I don't have the W&N bushings - I got the softer MTC ones as recommended in the install thread - my troubles appear to be from a lack of appropriate tool to get the job done (this is what I am working on) and the thickness of the powder coat adding to the difficulty. I'll post an update on that thread. Thanks.Hose- are you having trouble with the compliance bushings? By the tow hooks?

The ones from W&N?

If so- I can help with ones from an earlier production run.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine rebuild and engine bay resto thread - 2240284 '72 CS

- Thread starter Stevehose

- Start date

Love the A/C solenoid. I need to do that.It's been a while since I have updated this thread, I have been rolling around in my sweat under and in the engine bay in 95 degree heat and humidity hacking away at numerous resto and resto-mod projects for months now. Thanks to @sfdon the pieces I need to install my hi-flo oil pump are here so I have been able to shim the smaller chain & cog correctly and then proceed to assemble the remaining ancillary bits. At this point the block is de-rusted, primed, and painted with POR-15, that stuff is nasty in a good way - glossy, but some hours of heat will likely temper it. After installing the oil pump, I temporarily mounted the head to check the piston-head rotating clearance; this has kept me up at night worrying if the calculations for 10:1 pistons are correct. It has seemingly passed the test so onward to completely mounting the head with the last oem Goetze head gasket i could find (from Egypt). Also, the new Bosch SR444 850csi V12 starter is on (looks suitable for a B-52), the a/c solenoid, and a new German water pump. I have a new front lower timing cover crank seal coming - I ruined it despite having done this job a few times in the past. Duly noted not to try this again after the gummy kicks in...Once that is installed I will install both timing covers then the sump cover, all with appropriate amounts of Dirko sealant.

View attachment 170036

I also added an industrial petcock for the block coolant drain:

View attachment 170037

I got the chain tensioner from Maximillian, apparently they had some made specially for them (??) and of all the new crappy tensioners on the market (I've tried 'em all), this is the best. A friend made me a crank nut lock plate (he said Alpina made these back in the day??), Don says he's never seen a nut come off if properly installed but yours truly isn't going to ruin his streak!

View attachment 170038

In the resto-mod dept, I ran the a/c relay wires through the frame rail (accessed through the passenger floor pan hole), so the only stuff on the passenger fender from the firewall will be 2 reduced size barrier a/c hoses. I am sourcing a rubber seal to install on the perimeter edge of the front clip a/c hole, these were obviously hacked open by the dealer when installing a/c.

View attachment 170039

The engine bay is coming along slowly but surely, currently I am at war with the 2 lower subframe bushings, I hope to have a methodolgy to post on this soon if my latest install contraption/technique works. So far the bushings are winning 2-nil but there is still time on the clock...

Also like the Fumoto drain valve. I have these in the radiators on both of my BMWs - may add one like yours.

I've got one for the rad as well. The block needs a coupler to clear the vertical rib, I used this in M14 female to M14 male:Also like the Fumoto drain valve. I have these in the radiators on both of my BMWs - may add one like yours.

Steel Fitting, Female to Male, Multiple Size

Steel Fitting, M12 x 1.5 Female to M12x1.5 Male, HEX 22, L=43mm (1.7 inch) FTM523-M1215ST

autobahn88shop.com

Last edited:

This stuff works wonders with everything rubber. got it from Dick's thread I believe? The powder coating does make things tighter.

Linseed oil is very slippery also but not sure about long term effects.

Linseed oil is very slippery also but not sure about long term effects.

I use this stuff but it is probably the same ...

www.zoro.com

www.zoro.com

"Back in the day" (whatever that means?) we used it to shine up tires before Armor All.

Ags Ru-Glyde Tire Mounting and Rubber Lubricant, 1 Gallon Bottle RG-18 | Zoro

Order Ags Ru-Glyde Tire Mounting and Rubber Lubricant, 1 Gallon Bottle, RG-18 at Zoro.com. Great prices & free shipping on orders over $50 when you sign in or sign up for an account.

"Back in the day" (whatever that means?) we used it to shine up tires before Armor All.

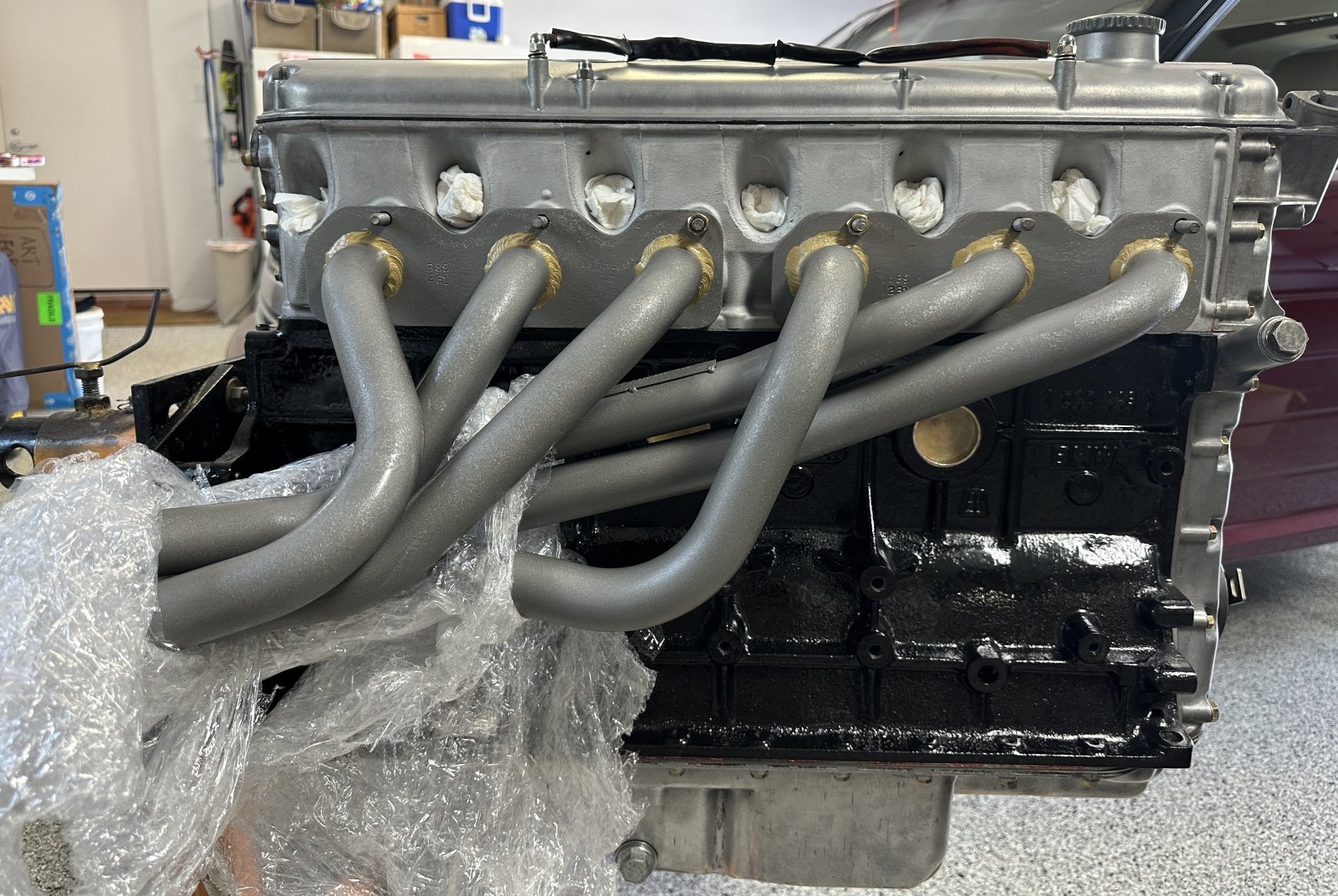

Subframe front tension bushings are in - never again. Test fitted the Stahls to ensure block drain valve clearance - looks ok.

Once the engine is in I will test fit again to see if they align with the center muffler inputs, then send off to be ceramic coated - am thinking satin silver color. Although dark bronze is tempting. They are so badass looking and already make my car go faster.

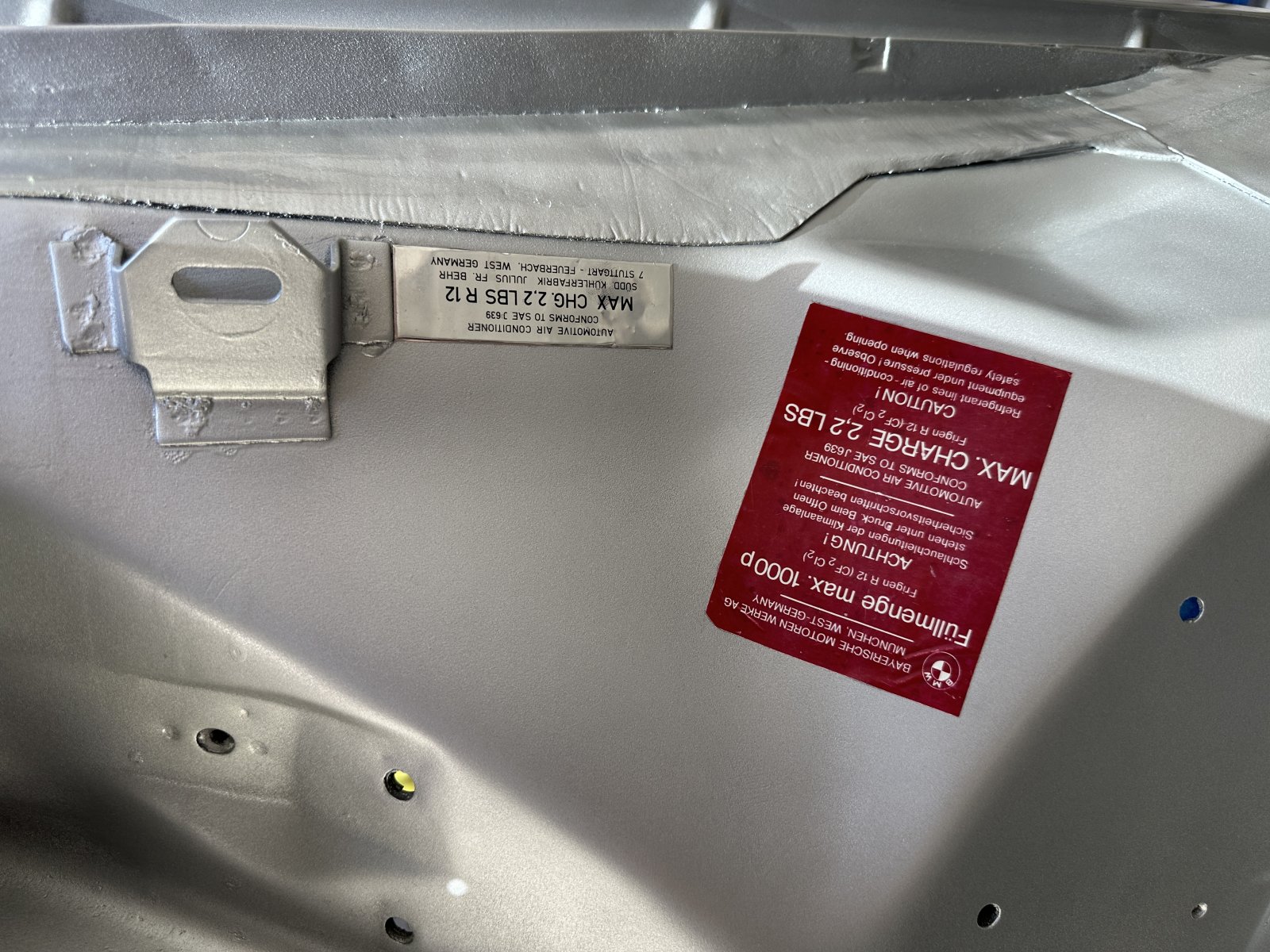

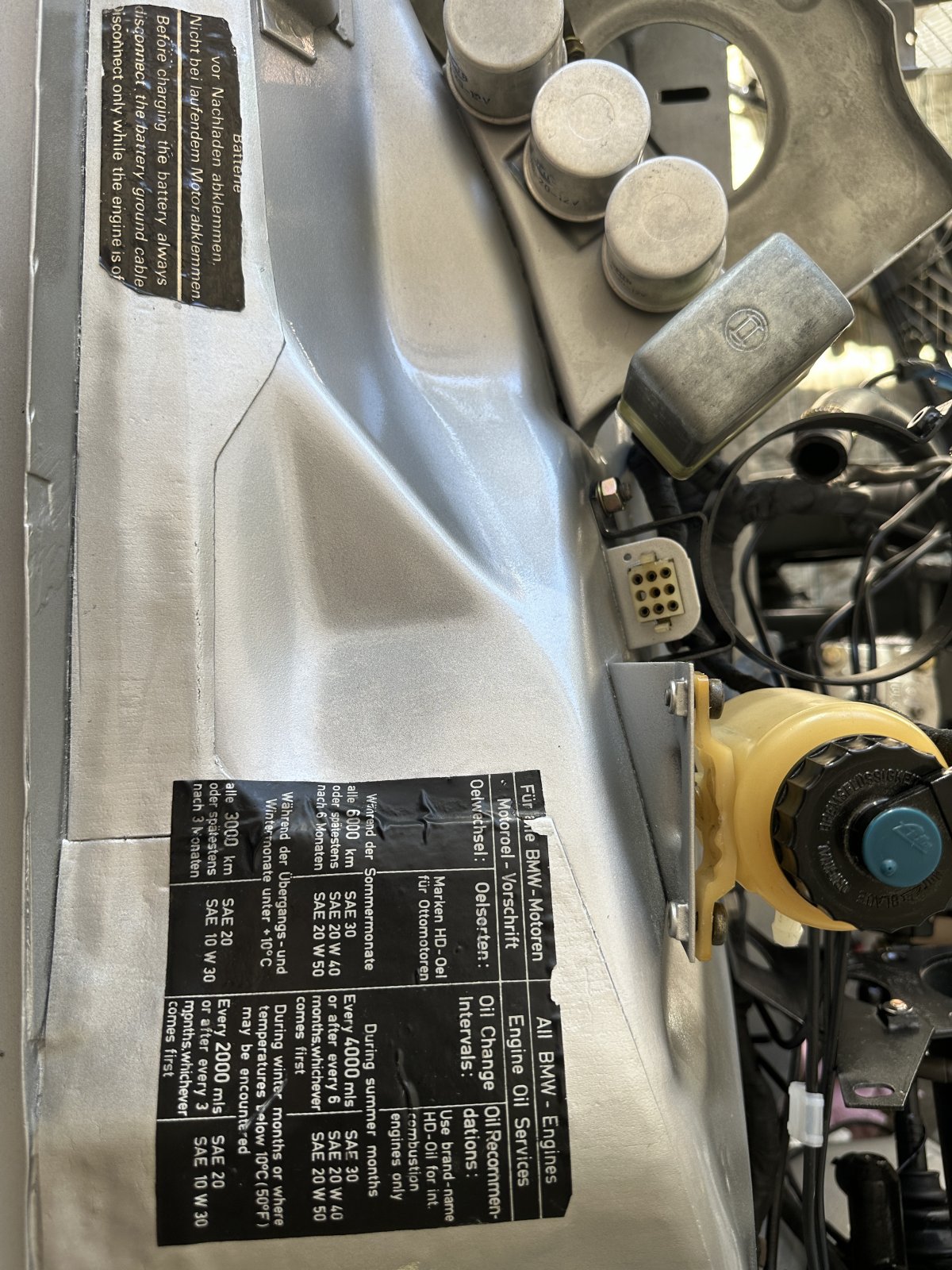

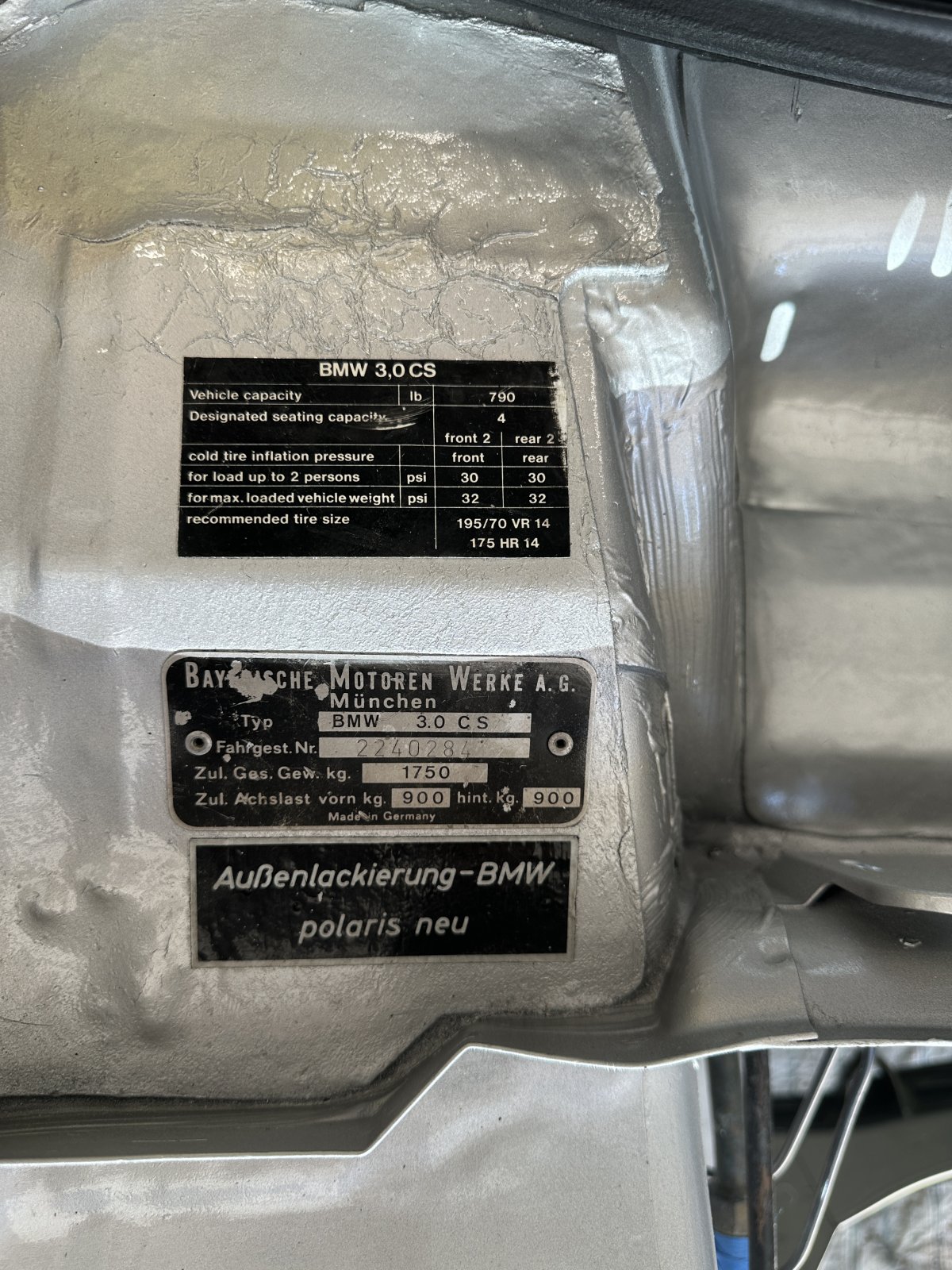

With engine bay painting complete (I went ahead and also repainted the area behind the firewall where the other 3 tar mats and the vent fan box are), I re-applied the original, somewhat worn and torn but pretty good considering, decals in exactly the same places, some still wrinkled and not exactly straight just as Franz did after his Weißbier break on the assembly line - I like the way it maintains the history of the car despite the refresh:

The VIN plate was obsessively masked and not removed, I protected what's left of the black ink by putting a piece of paper over that area so it wouldn't lift off when the tape was removed. Same for the DOT sticker on the driver side with the little self-destructing dots. The line across the top of the VIN plate is lighting, you can't tell it was masked nor is there any overspray. I hate overspray. The other 2 decals were reglued above and below it.

Waiting on new strut bearings, when painting the struts one fell over and landed on the bearing top plate, rendering it crunchy when rotating. Poof $$$ - doh. Then the struts go back in, the steering linkage attached, then brake lines secured. Then the engine goes in. Getting closer!

Once the engine is in I will test fit again to see if they align with the center muffler inputs, then send off to be ceramic coated - am thinking satin silver color. Although dark bronze is tempting. They are so badass looking and already make my car go faster.

With engine bay painting complete (I went ahead and also repainted the area behind the firewall where the other 3 tar mats and the vent fan box are), I re-applied the original, somewhat worn and torn but pretty good considering, decals in exactly the same places, some still wrinkled and not exactly straight just as Franz did after his Weißbier break on the assembly line - I like the way it maintains the history of the car despite the refresh:

The VIN plate was obsessively masked and not removed, I protected what's left of the black ink by putting a piece of paper over that area so it wouldn't lift off when the tape was removed. Same for the DOT sticker on the driver side with the little self-destructing dots. The line across the top of the VIN plate is lighting, you can't tell it was masked nor is there any overspray. I hate overspray. The other 2 decals were reglued above and below it.

Waiting on new strut bearings, when painting the struts one fell over and landed on the bearing top plate, rendering it crunchy when rotating. Poof $$$ - doh. Then the struts go back in, the steering linkage attached, then brake lines secured. Then the engine goes in. Getting closer!

Last edited:

72/E9

Member

Incredibly good stuff happening here - Congratulations!

And please keep posting updates!

And please keep posting updates!

Wow Steve! You are certainly turning an unfortunate incident into a genuine winning exercise. Absolutely love following your progress. A great template for anyone wishing to get in there and upgrade. Thanks for keeping us in the loop!

I had the chance of seeing his interpretation of a artform a couple of weeks ago. He didn't miss a brushstroke.

Thank you Steve.

Larry Louton

Thank you Steve.

Larry Louton

Very nice Steve. Alas, it is now time to polish up those relays. I suggest you consider the Mike Berger relay polishing technique: https://e9coupe.com/forum/threads/a-little-polish.42702/post-374336

Yeah, I've noticed, thanks for suggesting more work!Very nice Steve. Alas, it is now time to polish up those relays. I suggest you consider the Mike Berger relay polishing technique: https://e9coupe.com/forum/threads/a-little-polish.42702/post-374336

Steve, your great coupe is looking so much better. keep it up. on the relays, you could buy some new ones from @alprada70 ... they look so gooooooood

I used a wire wheel on the grinder. Took about a minute.Yeah, I've noticed, thanks for suggesting more work!

I used a wire wheel on the grinder. Took about a minute.

They're actually in pretty nice shape, the camera enhances flaws that the eye doesn't initially see. I like the ink stamped logos so I will likely keep them patinated. I will eventually get some from Alvaro once the coffers have been refilled. The regulator is NOS but is just there for looks.I used a wire wheel on the grinder. Took about a minute.

Steve, yours look fine. Mine didn’t look anything like that, and had no writing or ink stamp. They were quite battered.They're actually in pretty nice shape, the camera enhances flaws that the eye doesn't initially see. I like the ink stamped logos so I will likely keep them patinated. I will eventually get some from Alvaro once the coffers have been refilled. The regulator is NOS but is just there for looks.

View attachment 170883

That yours look ridiculously good, like the rest of your car did. I think the owner takes pretty good care of it.

If you are looking for a fresh relay base- let me know.

We have them 3D printed.

We have them 3D printed.

As fate would have it, my garage door counterbalance spring blew up last night and I can’t raise the door so I am dead in the water until the repairman can get here which won’t be for a week. Because the car is on stands 8 inches from the door, I can’t get any leverage to pull it up. Too bad because I was planning to drop the engine in this weekend but that must wait. In the meantime, I am getting my OCD on and cleaning up and hiding the modern accessory wires that have accumulated at the coil over the years. I previously did the same at the positive battery cable by installing a small vintage-looking fuse block on the firewall (same fuse style) and running the window relays, stereo amp, lights, etc through that. So now no accessories are bolted to the battery clamp. Clean.

The 123 distributor and fuel cutoff relay for the 3 Webers take power/signals from the coil but this was getting out of hand and looking too busy and aftermarket for me. So I replicated the 2 green and 3 black coil wires with fresh wire and put them into the original spade insulators I found on some original wiring harness pieces I bought from Murray a long time ago and now it’s finally been put into use. The yellowed plastic looks just right. Here is the test setup with my nos coil plug and orange diagnostic port harness wire. I’m keeping the radio interference suppressor for additional period goodness:

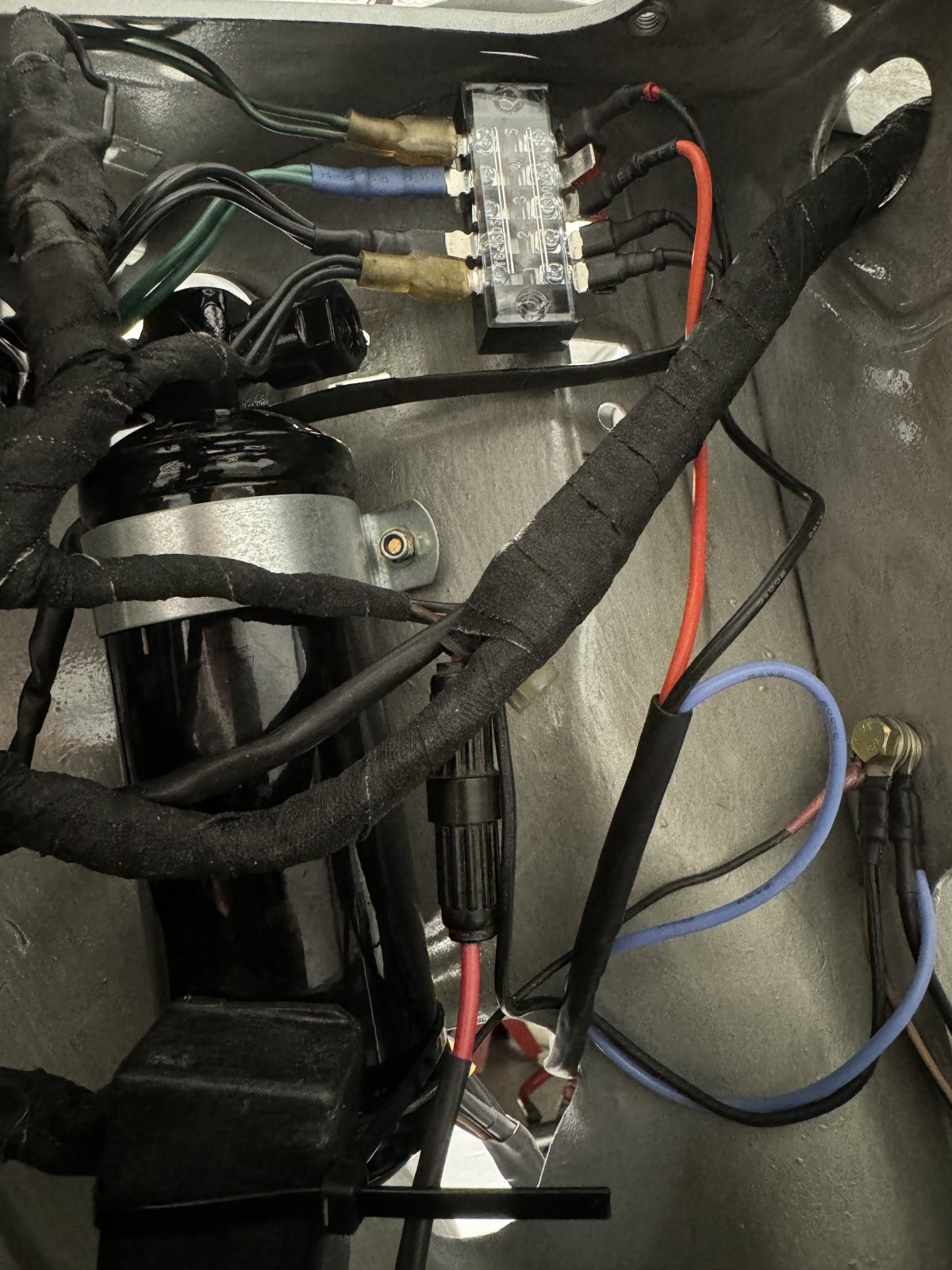

Then I made a junction box for all the other spade connections and mounted it behind the lights which is accessible through the light cover plate from above. I also re-taped the harnesses with fresh friction tape. And also relocated the grounds out of sight with an m6 bolt including a direct wire to the neg batt terminal. I don’t want half-assed grounding for my ignition and fuel systems:

Restored horn and relocated ac dryer yet to be hooked up.

Here’s the ac relay wired through the frame rail instead of all over the fender etc:

I will only have one ac hose going through the gash next to the relay, the reduced barrier hose is smaller and more flexible so the compressor to condenser hose will be routed through a hole in the clip from below - the only hose through the gash will be the thin condenser to evaporator hose. I have some rubber trim coming to line the perimeter of the hole. The car originally had some there to prevent chafing but it disintegrated when I removed it.

More obsession to follow!

The 123 distributor and fuel cutoff relay for the 3 Webers take power/signals from the coil but this was getting out of hand and looking too busy and aftermarket for me. So I replicated the 2 green and 3 black coil wires with fresh wire and put them into the original spade insulators I found on some original wiring harness pieces I bought from Murray a long time ago and now it’s finally been put into use. The yellowed plastic looks just right. Here is the test setup with my nos coil plug and orange diagnostic port harness wire. I’m keeping the radio interference suppressor for additional period goodness:

Then I made a junction box for all the other spade connections and mounted it behind the lights which is accessible through the light cover plate from above. I also re-taped the harnesses with fresh friction tape. And also relocated the grounds out of sight with an m6 bolt including a direct wire to the neg batt terminal. I don’t want half-assed grounding for my ignition and fuel systems:

Restored horn and relocated ac dryer yet to be hooked up.

Here’s the ac relay wired through the frame rail instead of all over the fender etc:

I will only have one ac hose going through the gash next to the relay, the reduced barrier hose is smaller and more flexible so the compressor to condenser hose will be routed through a hole in the clip from below - the only hose through the gash will be the thin condenser to evaporator hose. I have some rubber trim coming to line the perimeter of the hole. The car originally had some there to prevent chafing but it disintegrated when I removed it.

More obsession to follow!

Last edited:

The obsession is working out very nicely!