Looks awesome, it is kind of fun isn’t it?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine rebuild and engine bay resto thread - 2240284 '72 CS

- Thread starter Stevehose

- Start date

Yes it is, and very rewarding, especially when I am forced by extraneous circumstances to slow down and take my time. Otherwise, my lack of patience for this sort of thing can get the better of me.Looks awesome, it is kind of fun isn’t it?

Very nice to see how you are mixing new stuff while still preserving it's original elements.

How did you get the original labels of the fenders and reapply them? Heat gun?

How did you get the original labels of the fenders and reapply them? Heat gun?

Thanks, I keep what original stuff I can that still looks good. The decals are quite strong, I only slightly warmed them with a hair dryer because the tar underneath gets very gooey when warm (this is actually helpful when installing the deep-well tar mat that is just left of the blower motor which I heated to 175 degrees on a cookie sheet to soften it up and comply with the compound curves when pressing in, but I digress). I was able to grab a corner with tweezers and gradually pull up while helping the underside with a thin metal paint scraper - stiff but not sharp. Then once I could get my fingers to grip I continued the procedure until it was off, going very slowly to avoid tearing it. I re-applied using JB Weld clear 5 min epoxy spread thinly on the entire backside, positioned, and the excess wiped off. Small window of time before the glue sets.Very nice to see how you are mixing new stuff while still preserving it's original elements.

How did you get the original labels of the fenders and reapply them? Heat gun?

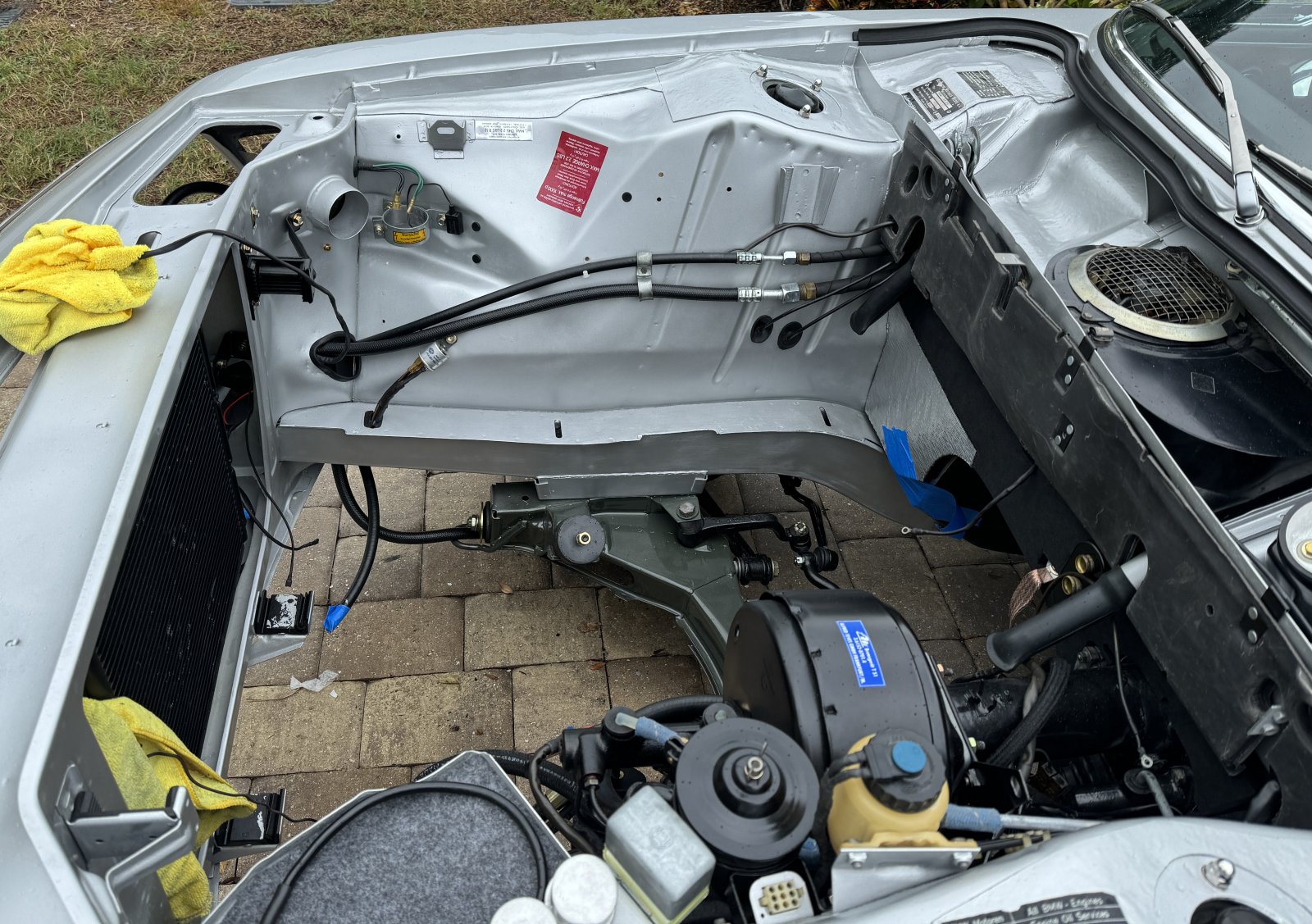

Quite the day today, the garage door repairman finally made it so I have been busting ass to get my car ready to get off the jack stands and push it out so he could have room. Today the car saw the light of day for the first time since May. And of course, it rained for the first time since then also but small price to pay. It’s ready for the engine which I will do after Thanksgiving.

Hotter than a wet t-shirt competition:

Hello daylight my old friend:

Quick pics during a break in the rain:

Still some loose ends in there but the light is at the end of the tunnel.

Hotter than a wet t-shirt competition:

Hello daylight my old friend:

Quick pics during a break in the rain:

Still some loose ends in there but the light is at the end of the tunnel.

Attachments

Last edited:

Looks amazing Steve, nerves will be on edge while the engine is going in, but that new engine will look great in the jewelry box of an engine bay!

I’ll be posting some things for the record if anyone is interested for their own car. First is a stainless clutch pivot with a grease fitting. This will never wear out or deform. I got it here:

A high quality item.

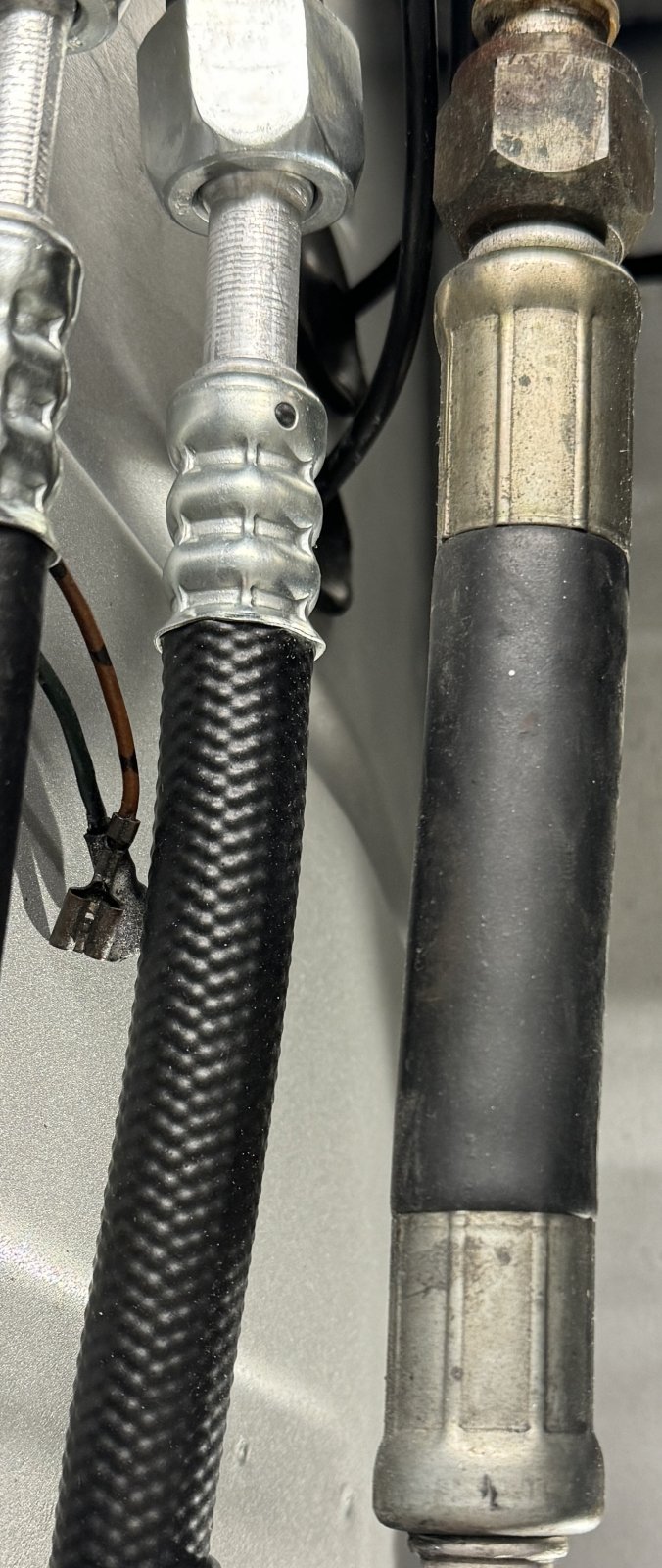

Here are pics of reduced-barrier a/c hoses vs regular size. Not only are they much smaller in diameter, they are very flexible which allows for more routing options. The large low pressure lines:

The small high pressure lines:

I got them here:

More "lessons learned" to follow.

Greasable Stainless Steel Clutch Fork Pivot Pin

Quite a lot of BMW's come with plastic clutch pivot pins, these pins are more than adequate for stock clutches, but on high performance clutches with higher clamping pressures and during hot track conditions, this isn't the case. These stainless pins will handle whatever clutch you have, and...

leogranderacing.com

A high quality item.

Here are pics of reduced-barrier a/c hoses vs regular size. Not only are they much smaller in diameter, they are very flexible which allows for more routing options. The large low pressure lines:

The small high pressure lines:

I got them here:

More "lessons learned" to follow.

Last edited:

That looks like a gated community?Quite the day today,

View attachment 172027

What are your neighbors mind, you restoring a "old rusty car" in your driveway?

Honest question.

Breiti

A good question - I’d say 2/3 of the neighborhood is not here during the months of may-oct so it’s very quiet (they live in northern climates). I am careful not to do anything messy in the driveway and everything else has been done in the (very small) garage. The immediate neighbors are very casual and have looked on with a combination of amusement and bewilderment at my obsession. One lady said she didn’t recognize me standing upThat looks like a gated community?

What are your neighbors mind, you restoring a "old rusty car" in your driveway?

Honest question.

Breiti

I've also found that helping your neighbors with their maintenance issues is helpful in keeping good relationships. In my youth, I was quite messy with a number of VWs and upset several neighbors which caused some mild blowback. Now my house is in a neighborhood with an HOA, but fortunately, they are relatively casual about enforcement and I'm careful to not make a mess outside.

With that grease fitting, isn't there the possibility of putting in too much grease so that it could contaminate the clutch surface? I'm not sure I'd be confident in my ability to inject minute amounts of grease at a time. And that old grease has to go somewhere eventually.

With that grease fitting, isn't there the possibility of putting in too much grease so that it could contaminate the clutch surface? I'm not sure I'd be confident in my ability to inject minute amounts of grease at a time. And that old grease has to go somewhere eventually.

I suppose so, but I think there is a lot of room for expansion under the fork lever before it gets elsewhere. After the initial recommended greasing, I would not inject more unless it started to make noise in a few years, which my original one did and made me crazy.With that grease fitting, isn't there the possibility of putting in too much grease so that it could contaminate the clutch surface?

I also bought it more for the stainless steel than the ability to grease it

Last edited:

Mike Goble

Well-Known Member

Never had a problem with loose rubbers...Leave the motor mounts and rubber as loose as possible

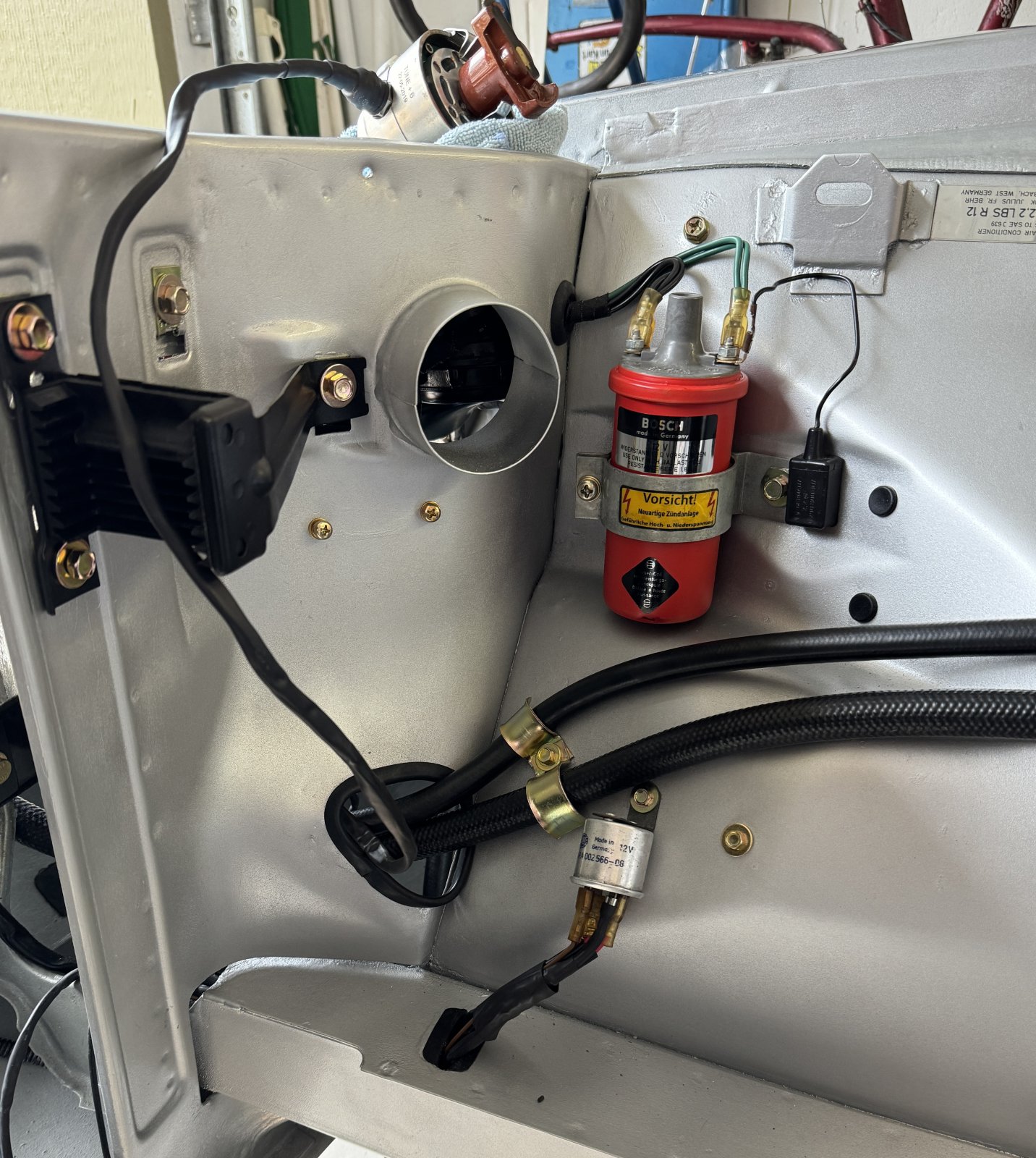

Finished up a few details before the engine install, hopefully next weekend. I cleaned up and installed the original radio suppression doohickey under the voltage regulator for the old school look, both are non-functional.

Installed the new a/c hose bracket assembly generously sent to me by a member here, and also installed a new in box Bosch red coil that I found in Japan (these things are getting very hard to find).

Next up, the big event with the engine install attempt.

Installed the new a/c hose bracket assembly generously sent to me by a member here, and also installed a new in box Bosch red coil that I found in Japan (these things are getting very hard to find).

Next up, the big event with the engine install attempt.

Today I hoisted the engine off the stand and installed the clutch and crank nut. A friend of mine made me a very nice nut lockplate which I installed. Torqued as close to 325 as I could estimate, loctite, and this lockplate ought to hold it securely enough

The engine goes in tomorrow am! Then a few weeks of attaching the peripherals and show time.

The engine goes in tomorrow am! Then a few weeks of attaching the peripherals and show time.

You need a job?

Good timing, could be a nice primer for my upcoming engine install. Take lots of pictures.Today I hoisted the engine off the stand and installed the clutch and crank nut. A friend of mine made me a very nice nut lockplate which I installed. Torqued as close to 325 as I could estimate, loctite, and this lockplate ought to hold it securely enough

View attachment 174245

The engine goes in tomorrow am! Then a few weeks of attaching the peripherals and show time.

Been there done thatToday I hoisted the engine off the stand and installed the clutch and crank nut. A friend of mine made me a very nice nut lockplate which I installed. Torqued as close to 325 as I could estimate, loctite, and this lockplate ought to hold it securely enough

View attachment 174245

The engine goes in tomorrow am! Then a few weeks of attaching the peripherals and show time.

good luck Steve

Wow, look at these …

Don says not necessary if correct torque (and some loctite) are used, but I figured I have it so on it went. He may have a few extra if you’d like me to get a price.Steve, looking good!

Do we feel a lockplate to be necessary? If you or someone has the CAD file for that Sendcutsend could likely laser cut 20 of those for a few $$ each...