Project 38: Install the original hex pattern sound deadener in the inner front fenders. This was not a task I was looking forward to.

The PO had chosen to not reinstall the hex patterned sound deadener after the body restoration. It is clear he did an exemplary job in sealing off the the new inner fender joiner panels. I get it - to always 'show your work' when it comes to rust repair and prevention. Well, now that we all know that that fine work is there, I prefer the original look of the hex patterned material.

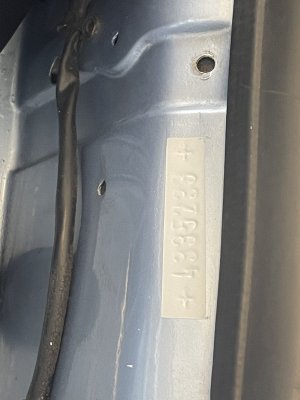

Image 9516 is a catalyzed high build primer that went on tonight. Hex material is from Chris at CS Werks with some light trimming. Like all painting projects it was 2 1/2 hours of prep and masking with about 4 minutes of paint application. Tomorrow its on to the Fjord base coat and then two coats of clear.

The PO had chosen to not reinstall the hex patterned sound deadener after the body restoration. It is clear he did an exemplary job in sealing off the the new inner fender joiner panels. I get it - to always 'show your work' when it comes to rust repair and prevention. Well, now that we all know that that fine work is there, I prefer the original look of the hex patterned material.

Image 9516 is a catalyzed high build primer that went on tonight. Hex material is from Chris at CS Werks with some light trimming. Like all painting projects it was 2 1/2 hours of prep and masking with about 4 minutes of paint application. Tomorrow its on to the Fjord base coat and then two coats of clear.

Attachments

Last edited: