Scott -- I had a variation on the blue wire problem Chris mentioned. The blue wire in my car had broken and been repaired with a solder joint. Over time the solder joint deteriorated increasing the resistance in the wire. Because of this increased resistance, the voltage flowing to the alternator was decreased and the alternator pumped out more juice in response to this erroneous signal. Fried both my battery and the diodes in my alternator, but thankfully nothing else in the car.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Baby is done... Thanks for all your help!!!!

- Thread starter scottevest

- Start date

-

- Tags

- restoration list

I can’t believe how complicated this all is. Thank you so very much. I will confer with Carrie on Monday unless you guys think I should have a mechanic do this work. Just can’t wait to get the car on the roadScott -- I had a variation on the blue wire problem Chris mentioned. The blue wire in my car had broken and been repaired with a solder joint. Over time the solder joint deteriorated increasing the resistance in the wire. Because of this increased resistance, the voltage flowing to the alternator was decreased and the alternator pumped out more juice in response to this erroneous signal. Fried both my battery and the diodes in my alternator, but thankfully nothing else in the car.

This is actually dual exhaust all the way from the frontTalking about twin tips, if I'm not wrong this is Paul C's car, this looks better since the body is modified to accept two tips, but would be even better if they came up 1 - 1½" more.

View attachment 49936 View attachment 49937 View attachment 49938

Getting closer.... Just talked to Benny and he agrees that subject to below, I will be on the road this week. I shared with him the information from here the alternator issues. I have a longer list but not bother Benny with the small stuff, e.g. fixing the BBS wheels, etc.

Benny,

I hope you had a great weekend.

Other than minor items, e.g. re-attaching numbers, it seems that we are near the end, subject to the list below. I think this list represents the remaining items:

I am super excited. Please let me know your thoughts on this.

Benny,

I hope you had a great weekend.

Other than minor items, e.g. re-attaching numbers, it seems that we are near the end, subject to the list below. I think this list represents the remaining items:

- Hood is not closing/opening properly, causing the paint to scrap on the front leading edge, drivers side. I believe adjustments are needed and then paint repair on leading edge.

- Windows not closing properly - first attach to charger to see if issue is not enough power or requires adjustments to ensure going up all the way and properly closing.

- finish painting/buffing on passenger door, and reattaching the trim, where new paint is

- Any additional work needed for fisheyes, etc.

- alternator issues: I have someone standing by today that can advise Gary on likely issues on the phone. It is likely something super simple.

- Drain Test - soak with water to ensure nothing leaks in

- final detail and review

I am super excited. Please let me know your thoughts on this.

UPDATE:

The ebay seller walked Gary through things and was able to get power directly to the dash with alternator producing power, so the alternator works fine, and likely the other one did too. Whew.... He was VERY helpful, and I highly recommend him.

He thinks it had something to do with the type of lightbulbs used, which although were not LED, may have been different, thus causing the issue. I am hoping Gary can track this down as I am now more certain than before that the problem was caused by switching lights or removing the dash and disturbing a wire or something. I hope and trust that the added costs for chasing this down will not be significant. Not sure if I should be responsible for paying these costs, but not going to argue at this point. I just want to get on the road. This is a microcosm of what a restoration can be like....

Gary got the passenger window working fast, but now has a bit of a gap. He is going to address, then deal with the driver's side, then the hood, then I'm on the road....by hopefully Wednesday.

I can't wait.

The ebay seller walked Gary through things and was able to get power directly to the dash with alternator producing power, so the alternator works fine, and likely the other one did too. Whew.... He was VERY helpful, and I highly recommend him.

He thinks it had something to do with the type of lightbulbs used, which although were not LED, may have been different, thus causing the issue. I am hoping Gary can track this down as I am now more certain than before that the problem was caused by switching lights or removing the dash and disturbing a wire or something. I hope and trust that the added costs for chasing this down will not be significant. Not sure if I should be responsible for paying these costs, but not going to argue at this point. I just want to get on the road. This is a microcosm of what a restoration can be like....

Gary got the passenger window working fast, but now has a bit of a gap. He is going to address, then deal with the driver's side, then the hood, then I'm on the road....by hopefully Wednesday.

I can't wait.

Benny just called. They found the issue. There was a loose wire behind the dash. They had to take the instruments out to track it down. I'm hoping this won't cost much, but fear that is wishful thinking. Benny said I will be on the road by Thur or Friday, assuming no other issues.

No matter what it costs, at this point you must get everything right. As my dad said "you ate the whole pig, might as well eat the tail"Benny just called. They found the issue. There was a loose wire behind the dash. They had to take the instruments out to track it down. I'm hoping this won't cost much, but fear that is wishful thinking. Benny said I will be on the road by Thur or Friday, assuming no other issues.

Now I understand where the expression, "it's like watching paint dry" comes from.... Painting/restoring a car takes forever. I recall in April being asked to overnight misc seals etc. in with the hope/expectation of it being done then. Down to a very very short list, but still not quite done. Apparently, lots of time working on getting the windows to close without gaps took a bit if time this week, and now the switches are screwed up a bit.... You guys were right about knowledge of these cars being helpful in the reassembly process especially. The windows and doors were perfect before we started, thanks to Bill Arnold in SF, but apparently getting them back together is not simple.

Fingers crossed it will be ready today, but not holding my breath.....

It will almost be Fall by the time it is done.

Fingers crossed it will be ready today, but not holding my breath.....

It will almost be Fall by the time it is done.

OMG... SOOOO EXCITED. Benny called me up shortly after I posted this and asked me to come down to take a look. WOW!!! Looks amazing!!!! He is making EVERYTHING right. The paint looks incredible.

Some minor things to take care off, but I am confident all will be done to my satisfaction and his. The next coupe is on the way to him, and it will be frame off restoration. I assume that some of the lessons learned on my coupe will be applied to the next one.

Do you want me to document that one, not to the degree of mine but a bit. I know Benny appreciated all your help, and has told me so.

Here's a live video done when I first got there:

Hi-res walk around:

Need to deal with the BBS wheels leaking. I will refer above to the suggestions.

Some minor things to take care off, but I am confident all will be done to my satisfaction and his. The next coupe is on the way to him, and it will be frame off restoration. I assume that some of the lessons learned on my coupe will be applied to the next one.

Do you want me to document that one, not to the degree of mine but a bit. I know Benny appreciated all your help, and has told me so.

Here's a live video done when I first got there:

Hi-res walk around:

Need to deal with the BBS wheels leaking. I will refer above to the suggestions.

Wow, great walk around. Beautiful! I could look at this car all day long.

Scott, I need a better look at that front spoiler when you get a chance.....

But maybe that's the point. It doesn't make itself too obvious. I like how it is "hidden", and it definitely accentuates the shark nose. Good choice!

But maybe that's the point. It doesn't make itself too obvious. I like how it is "hidden", and it definitely accentuates the shark nose. Good choice!

I agree. I bought the spoiler from CoupeKing without really researching, and was nervous I wouldn't like it, but I love it. The only thing I'm not sure of is the rectangular holes. Rectangular Fog lights I think would look odd, and not sure if intended for airflow or ?? I may try to see what rectangular fog lights would look like by photoshopping them in. BTW, assuming Benny wants me to document the other coupe he is doing soon, I think I will do so on Facebook e9 groups instead of here. Seems that not everyone appreciates my videos. Open to your constructive opinions. I can post just technical questions here and occasional videos but share much more on Facebook, which seems a bit more about sharing than this forum.Scott, I need a better look at that front spoiler when you get a chance.....

But maybe that's the point. It doesn't make itself too obvious. I like how it is "hidden", and it definitely accentuates the shark nose. Good choice!

Open to your thoughts.

me too!Wow, great walk around. Beautiful! I could look at this car all day long.

Scott, I believe the holes are there to ventilate your front brake rotors. They are meant to stay open for that purpose. The car looks great.The only thing I'm not sure of is the rectangular holes.

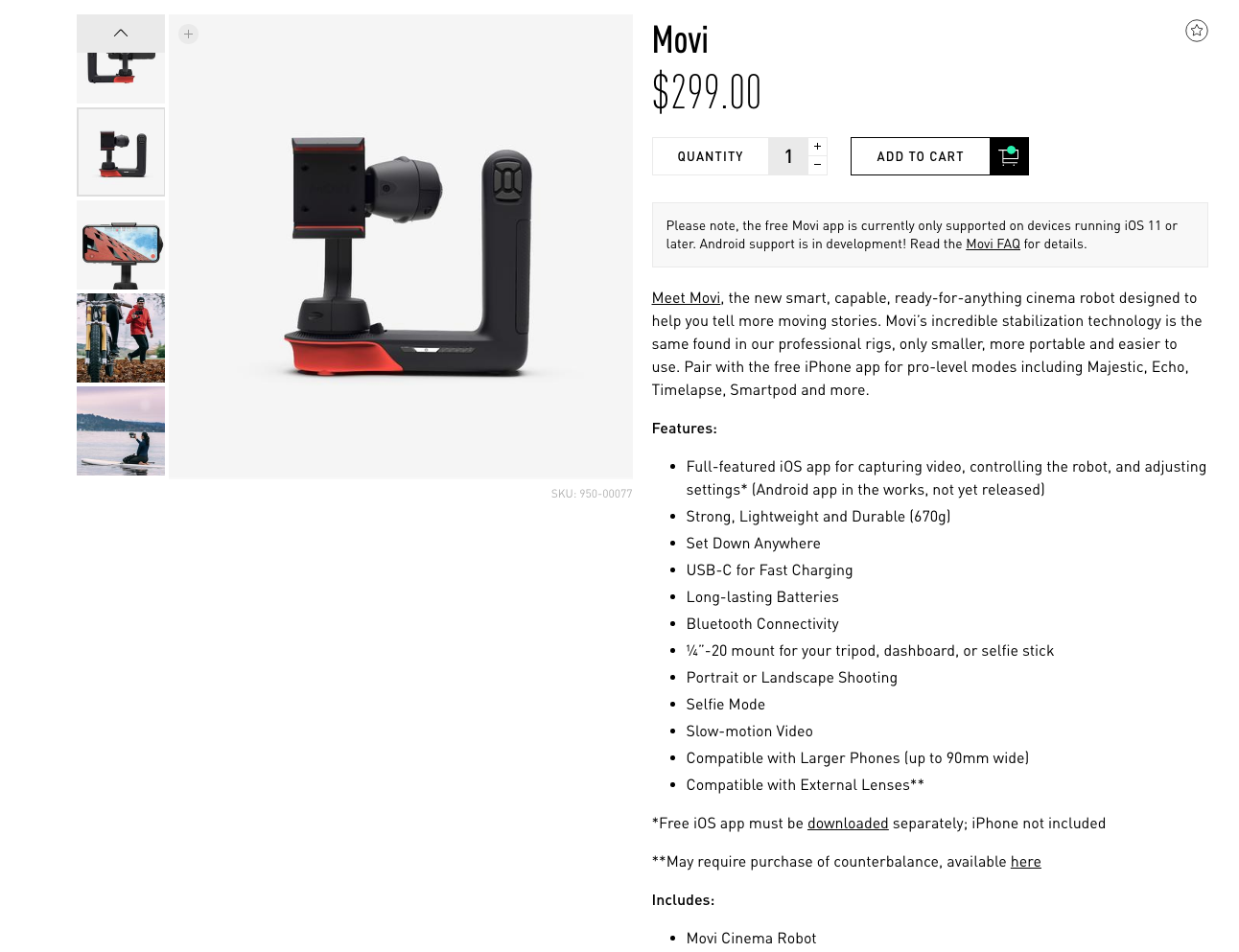

Scott, this should be your next purchase to take your video documenting to the next level!  insanely smooth walk arounds for really great vids.

insanely smooth walk arounds for really great vids.

https://store.freeflysystems.com/collections/movi/products/movi

https://store.freeflysystems.com/collections/movi/products/movi

I have something similar that I used to to be getting when I was filming but it is kind of unwieldy. I will use it for when the car is completed and detailedScott, this should be your next purchase to take your video documenting to the next level!insanely smooth walk arounds for really great vids.

https://store.freeflysystems.com/collections/movi/products/moviView attachment 50286

"frame off" is a bit of a misnomer for E9's

There is a front and rear subframe but no major chassis frame. Maybe better to call is a bare metal restoration.

In regards to your question of why it's so complicated when cars are all basically the same ...

(1) Many restoration shops are run by guys with passion and deep hands-on experience, but who are not good business/operation people. this leads to needless operational complexity. Things like detailed job specifications, change control process, and professional project management is what enables engineering companies to design and build tremendously complex new systems on time/budget. A small application of such principles (as you well know as a business owner), could make a big restoration shop much quicker and more efficient too.

(2) specialization: you've seen that while there are really NO E9 specific items when it comes to body and paint, there ARE a lot of E9 details regarding trim, mechanical, year on year changes etc. Plus there are period-specific specialties such as electrical systems, suspension, wood, trim, etc. For a shop to do everything efficiently and with high quality they generally have to have some specialization to a limited range of cars and periods, and subsystems.

John

There is a front and rear subframe but no major chassis frame. Maybe better to call is a bare metal restoration.

In regards to your question of why it's so complicated when cars are all basically the same ...

(1) Many restoration shops are run by guys with passion and deep hands-on experience, but who are not good business/operation people. this leads to needless operational complexity. Things like detailed job specifications, change control process, and professional project management is what enables engineering companies to design and build tremendously complex new systems on time/budget. A small application of such principles (as you well know as a business owner), could make a big restoration shop much quicker and more efficient too.

(2) specialization: you've seen that while there are really NO E9 specific items when it comes to body and paint, there ARE a lot of E9 details regarding trim, mechanical, year on year changes etc. Plus there are period-specific specialties such as electrical systems, suspension, wood, trim, etc. For a shop to do everything efficiently and with high quality they generally have to have some specialization to a limited range of cars and periods, and subsystems.

John

"frame off" is a bit of a misnomer for E9's

There is a front and rear subframe but no major chassis frame. Maybe better to call is a bare metal restoration.

In regards to your question of why it's so complicated when cars are all basically the same ...

(1) Many restoration shops are run by guys with passion and deep hands-on experience, but who are not good business/operation people. this leads to needless operational complexity. Things like detailed job specifications, change control process, and professional project management is what enables engineering companies to design and build tremendously complex new systems on time/budget. A small application of such principles (as you well know as a business owner), could make a big restoration shop much quicker and more efficient too.

(2) specialization: you've seen that while there are really NO E9 specific items when it comes to body and paint, there ARE a lot of E9 details regarding trim, mechanical, year on year changes etc. Plus there are period-specific specialties such as electrical systems, suspension, wood, trim, etc. For a shop to do everything efficiently and with high quality they generally have to have some specialization to a limited range of cars and periods, and subsystems.

John

John, that is my assessment too, without any real prior knowledge. Makes a ton of sense. Benny and team love what they do and are good at it, but could benefit from project management, as could most businesses I encounter. Ultimately, I am very happy with the end results or so I hope to see later this week once the final bits gets sorted out.

Things like getting windows operating properly would benefit from experience. As things stand, if they can't sort out getting the gaps etc out of the windows, I am inclined to find a shop in SLC or SF to address this so I can get on the road. Other than that along with the repainting on the passenger door and some minor fisheyes that can only be seen when you look at certain angles now, vs. before when they were very apparent on most angles, everything is done.

Need to sort out the BBS wheel leaks too, but otherwise I'm on the road by Thursday I believe, finally.

Scott

This is what you should get as your next toy.

http://race-cars.com/carsales/bmw/1533841904/1533841904lf.htm

This is what you should get as your next toy.

http://race-cars.com/carsales/bmw/1533841904/1533841904lf.htm

Regarding the BBS barrel air leaks. May have to, I hate to say it, have them rebuilt at a wheels shop. When I bought my 16" BBS RSs one wheel had a cracked rear barrel. I was able to just buy the rear barrel and have the wheels rebuilt by a wheel shop.