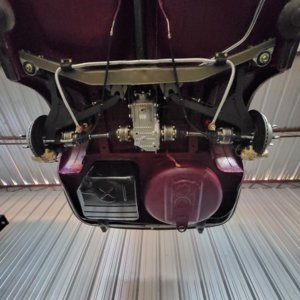

Only a few pics, as we only got a few hours in this afternoon. Here is the completed undercarriage.

Everything is in in the engine compartment. Most everything is hooked up. We added distilled water, P/S fluid and Oil. We attacked the clutch bleeding again after multiple failures on Saturday. One of the more consistently irritating processes on an E9. After pressurizing the reservoir and pulling vacuum on the slave, we still had air in the line. Its almost impossible to get an 8mm line wrench on that slave bleed screw as there no room to rotate the wrench as it hits the drive tunnel. I fab'd up this solution so we could open and close the valve more easily. It helped, but we still had some air in the line. The final fix was to remove the entire clutch slave cylinder, keeping the line attached. Then rotate the part so the bleed nipple is at 12 O'clock, then gently bleed it again and all the air will finally exit. So irritating. We now have a working clutch pedal.

Tomorrow we will try and start it and drive it.

Stay tuned for day 21.

Everything is in in the engine compartment. Most everything is hooked up. We added distilled water, P/S fluid and Oil. We attacked the clutch bleeding again after multiple failures on Saturday. One of the more consistently irritating processes on an E9. After pressurizing the reservoir and pulling vacuum on the slave, we still had air in the line. Its almost impossible to get an 8mm line wrench on that slave bleed screw as there no room to rotate the wrench as it hits the drive tunnel. I fab'd up this solution so we could open and close the valve more easily. It helped, but we still had some air in the line. The final fix was to remove the entire clutch slave cylinder, keeping the line attached. Then rotate the part so the bleed nipple is at 12 O'clock, then gently bleed it again and all the air will finally exit. So irritating. We now have a working clutch pedal.

Tomorrow we will try and start it and drive it.

Stay tuned for day 21.