Hey Stephen, It's looking good! It rained enough last night that you could have had a pool for a day...

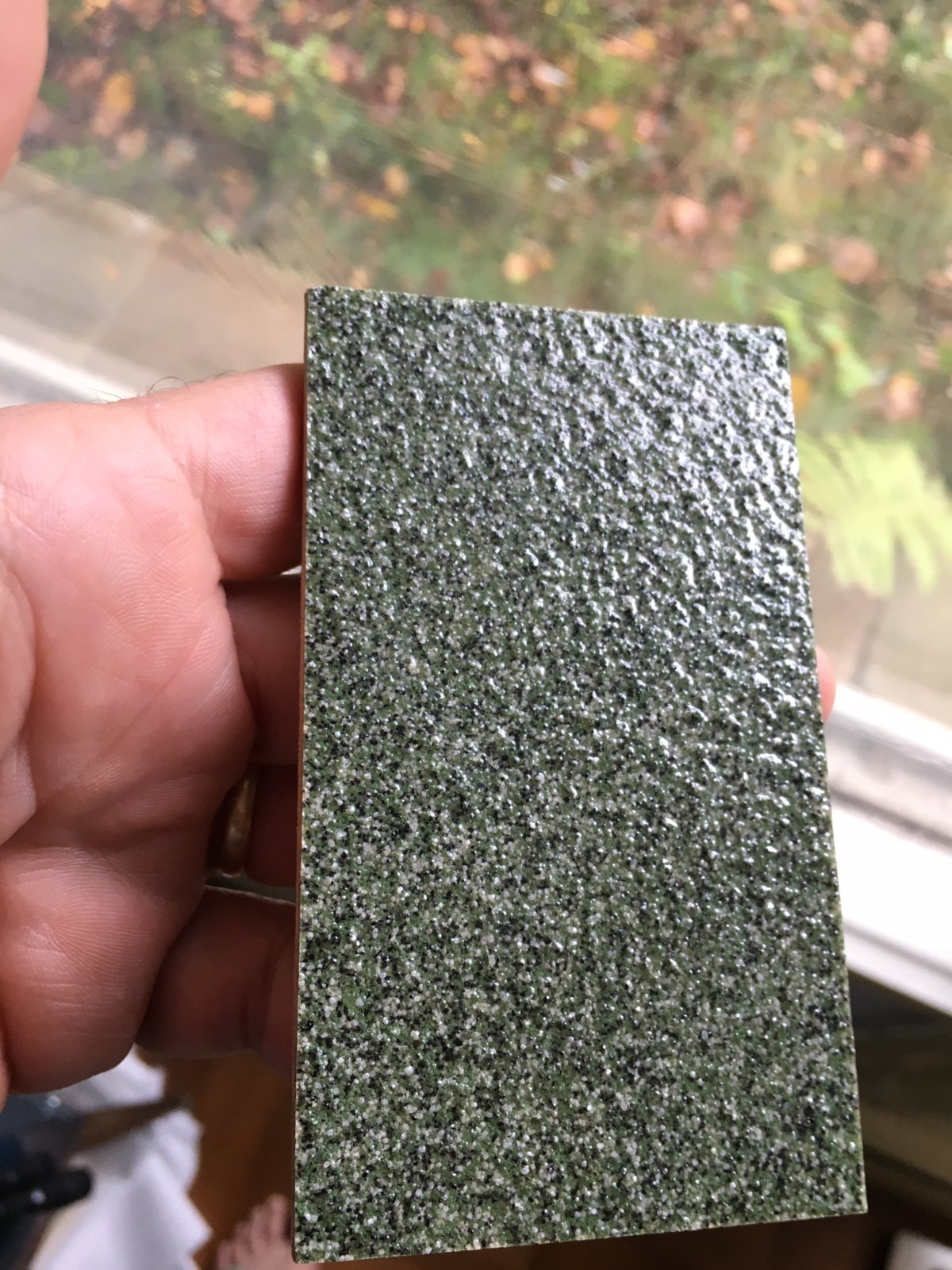

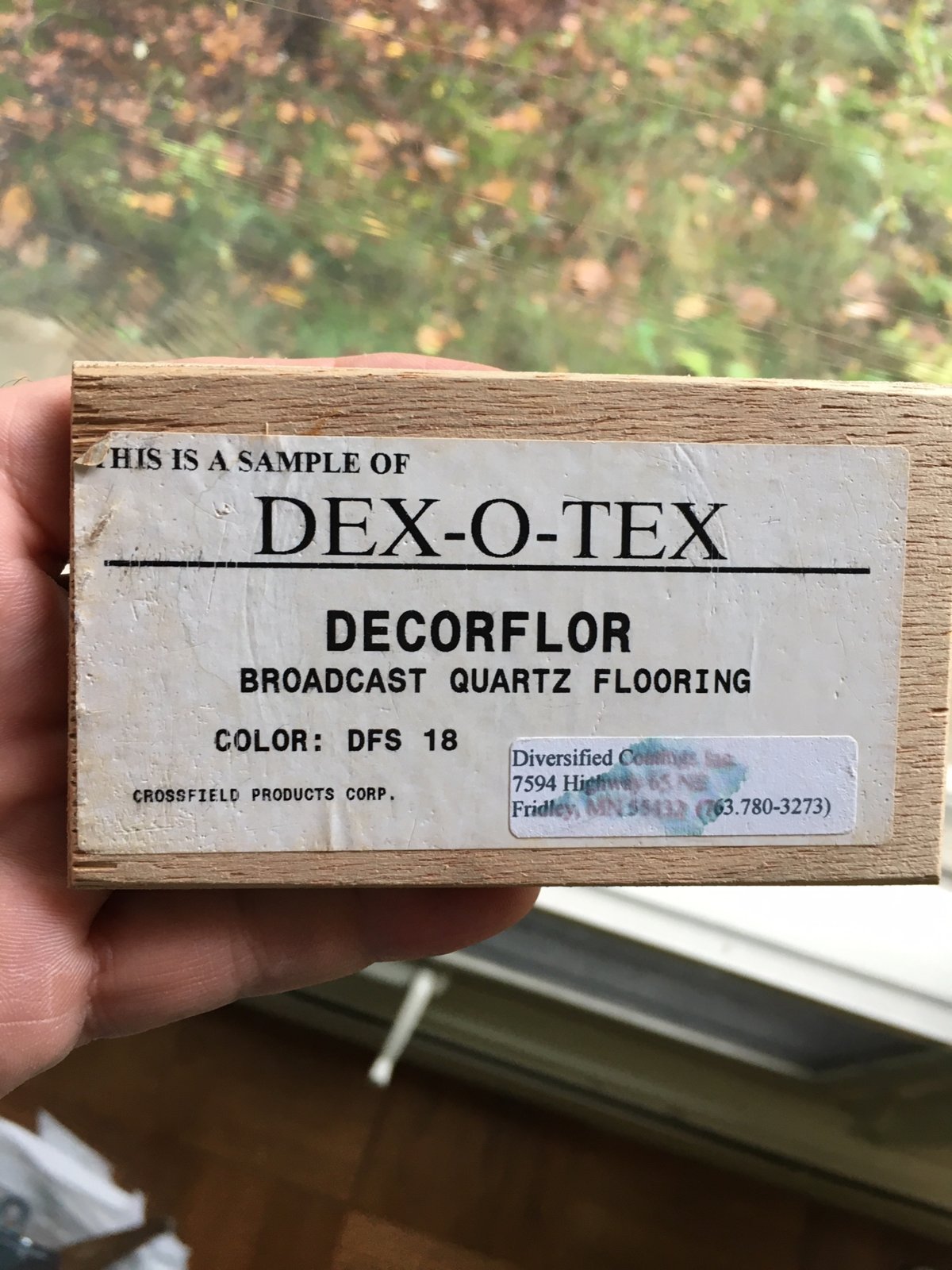

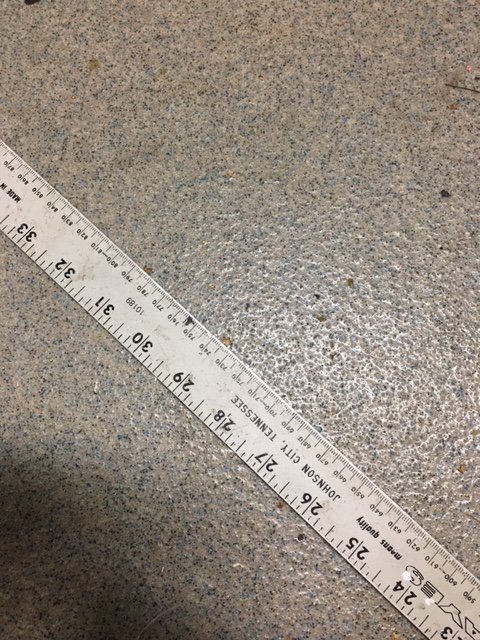

When I poured new concrete on our garage 12 years ago I used a an epoxy product with broadcast 3M quartz granules. It provides an attractive grippy and durable surface that can almost infinitely be varied in hue by the use of different color granules. Although I'm a consummate DIYer, this is one where I really felt it was worth having someone apply a better product than I could get and have had the experience of having done it 100s of times. It's a one-way trip and if it doesn't work out at first, difficult and spendy to unwind and re-do.

Pic of a sample below and the product on my floor 12 years later. The sample is NOT the same color mix I had applied.

I have the contact info of the guy who did it for me, if you're interested.

When I poured new concrete on our garage 12 years ago I used a an epoxy product with broadcast 3M quartz granules. It provides an attractive grippy and durable surface that can almost infinitely be varied in hue by the use of different color granules. Although I'm a consummate DIYer, this is one where I really felt it was worth having someone apply a better product than I could get and have had the experience of having done it 100s of times. It's a one-way trip and if it doesn't work out at first, difficult and spendy to unwind and re-do.

Pic of a sample below and the product on my floor 12 years later. The sample is NOT the same color mix I had applied.

I have the contact info of the guy who did it for me, if you're interested.