That copper manifold is a work of art.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Raven gets a new nest

- Thread starter autokunst

- Start date

Dohn

Well-Known Member

The Phantom of the Garage...

HonaloochieBoogie

Well-Known Member

A+ for cool factor. Wasn’t it Abraham Lincoln who said “ if it’s on the internet, it must be true.”?

Your compressor should be fine for a weekend warrior. I've had a similar one in my garage for about 30 years, minus the pipe organ.

You can give concerts! I suggest Bach as a starter.

Cabin is really beautiful, so is the car.

Amazing. Lots of expensive valves. Had you thought about doing it horizontally so you only need one drain valve?

I‘ve heard about using an application air conditioning condenser (tube & fin) with a drain valve soldered into the bottom.

www.garagejournal.com

www.garagejournal.com

And low end version

forum.langmuirsystems.com

forum.langmuirsystems.com

Why? Because they are compact and cheap. I’ve heard people mount these so the air flow from the compressor pulley vanes also flows across the condenser fins. The only challenge is adapting the fittings.

John

I‘ve heard about using an application air conditioning condenser (tube & fin) with a drain valve soldered into the bottom.

Compressor after cooler

If you already have an autodrain at the bottom of your tank, just run a copper line to the bottom ****** before the autodrain and let the tank drain get rid of the water. Save a couple bucks.

And low end version

Diy air compressor Aftercooler

Since using my plasma table and having a smaller air compressor, I have been constantly fighting water in my line. So after some research I found that guys are installing after coolers with their air compressors to bring down the temperature as close to ambient as possible, so that then you can...

forum.langmuirsystems.com

forum.langmuirsystems.com

Why? Because they are compact and cheap. I’ve heard people mount these so the air flow from the compressor pulley vanes also flows across the condenser fins. The only challenge is adapting the fittings.

John

Last edited:

Amazing. Lots of expensive valves. Had you thought about doing it horizontally so you only need one drain valve?

I‘ve heard about using an application air conditioning condenser (tube & fin) with a drain valve soldered into the bottom.

Compressor after cooler

If you already have an autodrain at the bottom of your tank, just run a copper line to the bottom ****** before the autodrain and let the tank drain get rid of the water. Save a couple bucks.www.garagejournal.com

And low end version

Diy air compressor Aftercooler

Since using my plasma table and having a smaller air compressor, I have been constantly fighting water in my line. So after some research I found that guys are installing after coolers with their air compressors to bring down the temperature as close to ambient as possible, so that then you can...forum.langmuirsystems.com

Why? Because they are compact and cheap. I’ve heard people mount these so the air flow from the compressor pulley vanes also flows across the condenser fins. The only challenge is adapting the fittings.

John

Nah... too pedestrian for him. Above all else, he's an aesthete...

Why would I spend my time and energy sourcing a used condenser, figuring out how to adapt the fittings, and live with the reduced air flow when I can craft a beautiful copper menagerie and achieve a theoretic 300CFM? Honestly, the parts for this cost about the same as a similar CFM, good quality commercially available dryer. It was an easy choice for me.

Amazing. Lots of expensive valves. Had you thought about doing it horizontally so you only need one drain valve?

I‘ve heard about using an application air conditioning condenser (tube & fin) with a drain valve soldered into the bottom.

Compressor after cooler

If you already have an autodrain at the bottom of your tank, just run a copper line to the bottom ****** before the autodrain and let the tank drain get rid of the water. Save a couple bucks.www.garagejournal.com

And low end version

Diy air compressor Aftercooler

Since using my plasma table and having a smaller air compressor, I have been constantly fighting water in my line. So after some research I found that guys are installing after coolers with their air compressors to bring down the temperature as close to ambient as possible, so that then you can...forum.langmuirsystems.com

Why? Because they are compact and cheap. I’ve heard people mount these so the air flow from the compressor pulley vanes also flows across the condenser fins. The only challenge is adapting the fittings.

John

Why would I spend my time and energy sourcing a used condenser, figuring out how to adapt the fittings, and live with the reduced air flow when I can craft a beautiful copper menagerie and achieve a theoretic 300CFM? Honestly, the parts for this cost about the same as a similar CFM, good quality commercially available dryer. It was an easy choice for me.

So, if that architect thing doesn't work out for you, I'll bet there is a market for these.

Last edited:

I bought that model compressor 20 years ago used and it is at home in the garage. At my shop I have an 80 Gallon, 5 HP 2 stage unit. While better, I did a reasonable amount of bead blasting with the old unit and didn't kill it. It is great for general purpose stuff.

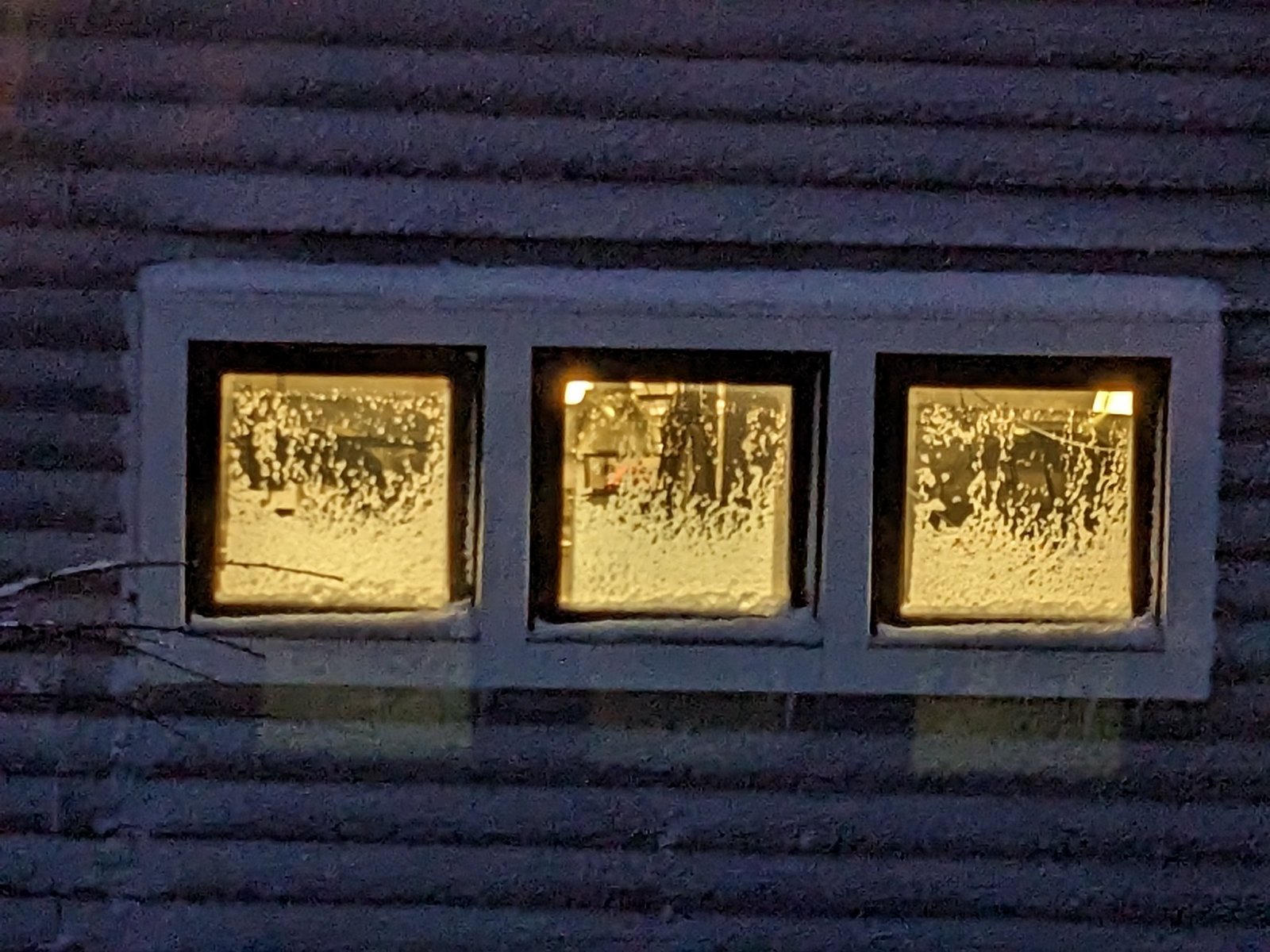

Just to give all of you California, Florida, and Atlanta folks (fill in the rest of the warm weather locations as you will) a dose of wonderful midwest weather (and I am being sincere), here is a shot of Raven's nest that Amy took this morning on our way out to shovel the neighborhood this morning. In our neighborhood we probably only got about 6" to 8", but there was a lot of drifting that created some deeper zones.

If you look real close, you might be able to make out an e9 chassis through the windows.

If you look real close, you might be able to make out an e9 chassis through the windows.

I grew up in central Wisconsin. A perfect place, summer and winter...when I was a kid.

I think I see a roof line and a wing window frame. Really not sure. The street light is still on and the sun is not up yet. Here is Solebury, Bucks County PA today's high was 57. It will dive into the low 40s tomorrow before recovring for the next 10 days mostly into the 50s. Bizarre winter we are having here. A bit unnerving.