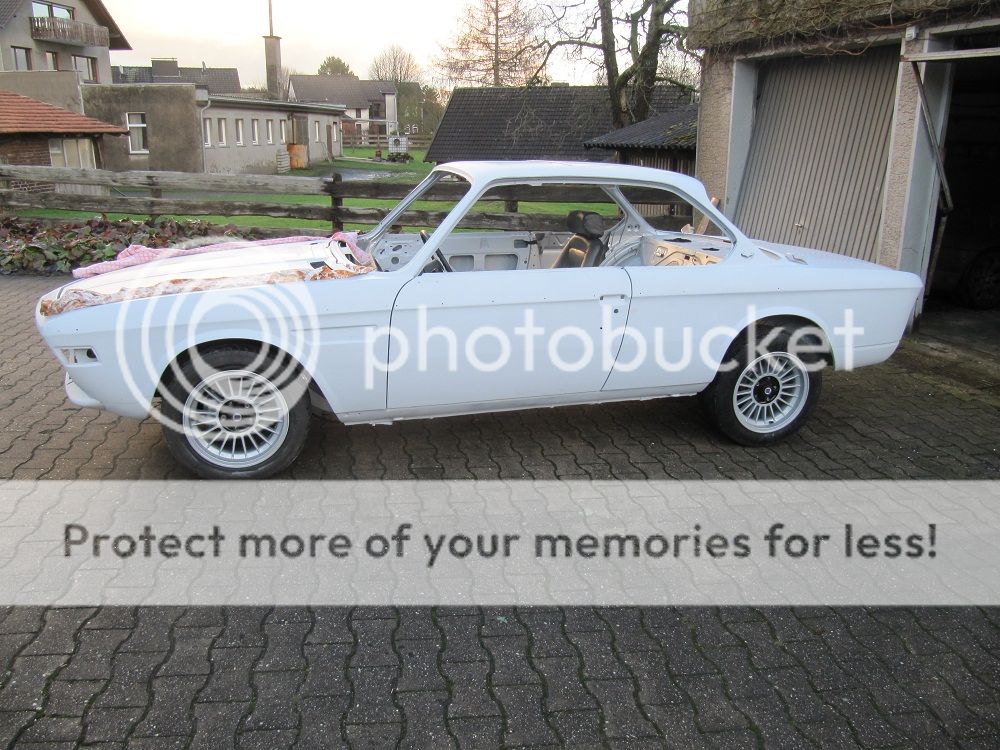

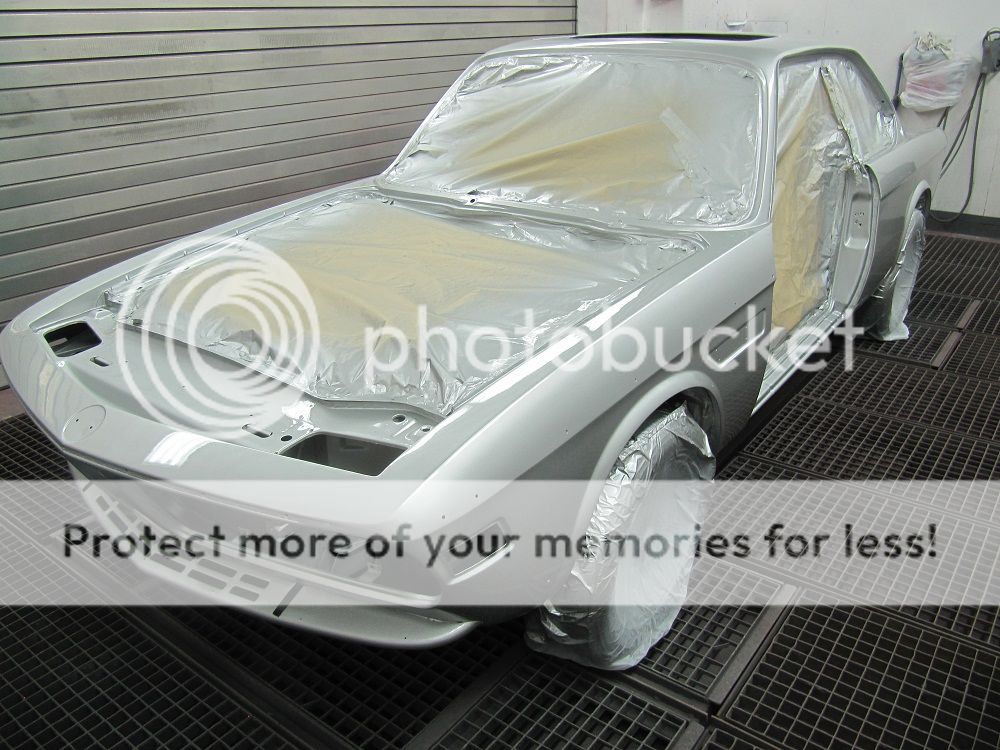

as next steps I decided in the meantime not only to close the remaining gaps and dents of the body with plastic filler. Prior to this I tried to tin the transitions and weldings as good as possible, because this was the first attempt for me.

It worked out very fine so far. Of course the majority of the 4 Kilos I needed was to tin the floor of my garage :-D but in fact there was luckily also some stuff remaining on the desired spots.

This process costs at least more than 10 hours work, but I find it worth at the end. The result is, that there's only a thin layer of filler needed and the spots are getting a good rigidity against twist or vibration, so that there's no higher risk of cracks in the paint later on - I hope so. :???:

In the meantime I also disassambled and sandblasted the complete suspension and transmission together with some engine parts.

I originally planned to have most of these parts powder coated, but decided to paint them instead by myself with 4 layers (Brantho Nitrofest, 2K-sprayfiller, black or aluminium colourlayer and clear coat). Should be sufficient resistent for everything and I had the complete process in my own hands.

Also in the meantime I started the exchange of the intake manifold from my motronic engine to the old and more original look.

Target was to keep as much as possible from the existing parts. I got a complete manifold of a 633 csi engine from a wrackyard for a good price and found out, that there's already an engine existing which is using the lower piece of the old manifold in combination with the motronic injectors. A buddy gave me this hint, that the Alpina B7 Turbo in an E28 chassis is doing like this. They just add their own upper manifold together with a specific fuelrail and pressure regulator.

There was also coming a lot of informations for this exchange from Don, special thanks again to him. It's absolutely unbelievable how helpful some of you guys out there are !!!

My final approach now is to modify just the fuel rail of my engine. The presure regulator had to be moved and the holders needed a certain change. The result is also shown in the attached pictures. The throttle has also to be a little bit modified, but wasn't also a big deal. Now I'm only in the need of some customized hoses for the idle valve and then I'm optimistic, that the machine's able to run when it goes back to the car.

So far for the moment

cheers

Ingo

It worked out very fine so far. Of course the majority of the 4 Kilos I needed was to tin the floor of my garage :-D but in fact there was luckily also some stuff remaining on the desired spots.

This process costs at least more than 10 hours work, but I find it worth at the end. The result is, that there's only a thin layer of filler needed and the spots are getting a good rigidity against twist or vibration, so that there's no higher risk of cracks in the paint later on - I hope so. :???:

In the meantime I also disassambled and sandblasted the complete suspension and transmission together with some engine parts.

I originally planned to have most of these parts powder coated, but decided to paint them instead by myself with 4 layers (Brantho Nitrofest, 2K-sprayfiller, black or aluminium colourlayer and clear coat). Should be sufficient resistent for everything and I had the complete process in my own hands.

Also in the meantime I started the exchange of the intake manifold from my motronic engine to the old and more original look.

Target was to keep as much as possible from the existing parts. I got a complete manifold of a 633 csi engine from a wrackyard for a good price and found out, that there's already an engine existing which is using the lower piece of the old manifold in combination with the motronic injectors. A buddy gave me this hint, that the Alpina B7 Turbo in an E28 chassis is doing like this. They just add their own upper manifold together with a specific fuelrail and pressure regulator.

There was also coming a lot of informations for this exchange from Don, special thanks again to him. It's absolutely unbelievable how helpful some of you guys out there are !!!

My final approach now is to modify just the fuel rail of my engine. The presure regulator had to be moved and the holders needed a certain change. The result is also shown in the attached pictures. The throttle has also to be a little bit modified, but wasn't also a big deal. Now I'm only in the need of some customized hoses for the idle valve and then I'm optimistic, that the machine's able to run when it goes back to the car.

So far for the moment

cheers

Ingo

Attachments

Last edited: