Damn that is nice work!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Raven e9 project

- Thread starter autokunst

- Start date

-

- Tags

- restoration list

Nice welding! Don’t forget to grease the casters again. When I welded casters the grease cooked out, but they were 1/5th the size of yours.

Last edited:

Impressively mad welding skills! Those beads look amazing.

Mark, thanks for the grease tip. I pumped them full of grease this afternoon after I read your suggestion. These are pretty large and the grease seemed fine. But better safe than sorry. I'd removed the paint in the areas I was actually welding, but additional paint burned off while I was attaching them and it smelled terrible. I also learned that the zerk fittings are junk on these casters. Hopefully I'll never have to grease them again.Nice welding! Don’t forget to grease the casters again.

Damn that is nice work!

Thank you! I do prefer if the beads look pretty. But I was at least as concerned about good penetration, no porosity, inclusions or undercutting. I don't know if my welds would pass a commercial test program, but I am quite certain this dolly is strong and will serve its intended purpose.Impressively mad welding skills! Those beads look amazing.

Very nice and clean welds and nice job on the fab work...

After just finishing a 5 year rebuild of my period correct hot rod, my suggestions without getting into all the nitty gritty details would be to:

Document everything you do or remove with photos. And don't get to close up (says the photographer) or you won't know what your looking at.

I took hundreds and hundreds of photos, many with a DSLR camera. While she was at the metal shop ( 1 year) I categorized the photos and went online and had 4x6 prints made and then put them in a box like a card index with each category labeled. Looking at photos on a computer is not great.

Actually try to get commitments from people on time for work. I had to really get on my metal guys case to even get it done in a year.

All kinds of ways to incentivise this process if you want it to get done in a reasonable time. I did all the disassembly and re-assembly myself. If you just hire someone to do it all they may get it done quicker to get paid. I was paying guys for metal and paint work as it went along. Probably better ways to do this.

Buy all the parts you need as quickly as possible. There are going up in price astronomically and inventory is going down quickly. Thank heaven for Walloth and Nesch in Germany.

Make an outline game plan. This helps keep you on track with each part and process. Multitasking is great too!

Actually one of the more intense difficult things I have ever done, except raising two boys.

Ask questions and don't feel stupid. I didn't ask enough because I thought I knew or could figure out.

Go rob a bank because you'll need it. LOL. $60k in mine and I did all the work.

Gary

Document everything you do or remove with photos. And don't get to close up (says the photographer) or you won't know what your looking at.

I took hundreds and hundreds of photos, many with a DSLR camera. While she was at the metal shop ( 1 year) I categorized the photos and went online and had 4x6 prints made and then put them in a box like a card index with each category labeled. Looking at photos on a computer is not great.

Actually try to get commitments from people on time for work. I had to really get on my metal guys case to even get it done in a year.

All kinds of ways to incentivise this process if you want it to get done in a reasonable time. I did all the disassembly and re-assembly myself. If you just hire someone to do it all they may get it done quicker to get paid. I was paying guys for metal and paint work as it went along. Probably better ways to do this.

Buy all the parts you need as quickly as possible. There are going up in price astronomically and inventory is going down quickly. Thank heaven for Walloth and Nesch in Germany.

Make an outline game plan. This helps keep you on track with each part and process. Multitasking is great too!

Actually one of the more intense difficult things I have ever done, except raising two boys.

Ask questions and don't feel stupid. I didn't ask enough because I thought I knew or could figure out.

Go rob a bank because you'll need it. LOL. $60k in mine and I did all the work.

Gary

I think that @autokunst and I subscribed to the same philosophy of learn as much as we can and hoard as many parts as possible to kick off the build. Being actievly engaged on the forum for the last (five!!!) years has really helped me understand many of the caveats of the car. @autokunst has been participating religiously as well. Stephen beat me to the punch on documenting hours. I intend to do this, and will continue to document spend as well. So far I'm all spend and no hours!

To add to what @m5bb mentioned about photos. I actually bought a amazon ripoff "go pro" with a headband mount and LED safety glasses. I intend to record the entire tear down process in HD. I purchased a bolt diameter/pitch/length gauge, and intend to narrate the size of every bolt quickly as I tear it down. The goal is to take no pics, and have the sizes for all bolts. I think this will help later when I ultimately hand stuff off to a zinc plating shop. I already have a very good handle on where everything belongs on the car, but particular things like the dash, doors and the motor have a number of bits to keep track off. I don't intend to publish the videos, but I'll cross that bridge when I get off my butt and perform the tear down. I did this recently with my camper restoration, and the thought of editing the content is a little overwhelming.

To add to what @m5bb mentioned about photos. I actually bought a amazon ripoff "go pro" with a headband mount and LED safety glasses. I intend to record the entire tear down process in HD. I purchased a bolt diameter/pitch/length gauge, and intend to narrate the size of every bolt quickly as I tear it down. The goal is to take no pics, and have the sizes for all bolts. I think this will help later when I ultimately hand stuff off to a zinc plating shop. I already have a very good handle on where everything belongs on the car, but particular things like the dash, doors and the motor have a number of bits to keep track off. I don't intend to publish the videos, but I'll cross that bridge when I get off my butt and perform the tear down. I did this recently with my camper restoration, and the thought of editing the content is a little overwhelming.

As I type this, I have taken 911 photos, and I am at the tail end of "disassembly". I don't plan on printing them as I like to sort through them on the computer. But I take them in the order I disassembled, and they make sense (to me). Some are further back, but many are close up. We'll see how well I can connect the dots...Document everything you do or remove with photos.

This one is easy - I plan to do all the work myself (save probably for paint). So my commitment is only that I am enjoying the process. So far, that is a big YES!Actually try to get commitments from people on time for work.

Couldn't agree more. This forum has transformed my life in more than one way, and I plan to rely (pretty heavily) on the knowledge and kindness of the forum members to contribute to all aspects of "correctness" - whether that is correct E9 details, and even correct ways to do various tasks that I am stuck on. Love this forum!Ask questions and don't feel stupid.

Interesting. I do not plan to do that - ha ha. But will be very interested in seeing how well it works for you. Instead, in addition to my photos I have parts and fasteners sealed in labeled bags - hundreds of them. Then the bags and parts are sorted loosely in labeled bins. If an item was attached with (4) bolts, the item and the (4) bolts are in a bag and labeled. Now, finding the right bag will be another story...I intend to record the entire tear down process in HD. I purchased a bolt diameter/pitch/length gauge, and intend to narrate the size of every bolt quickly as I tear it down.

Day 81

79.25 hours

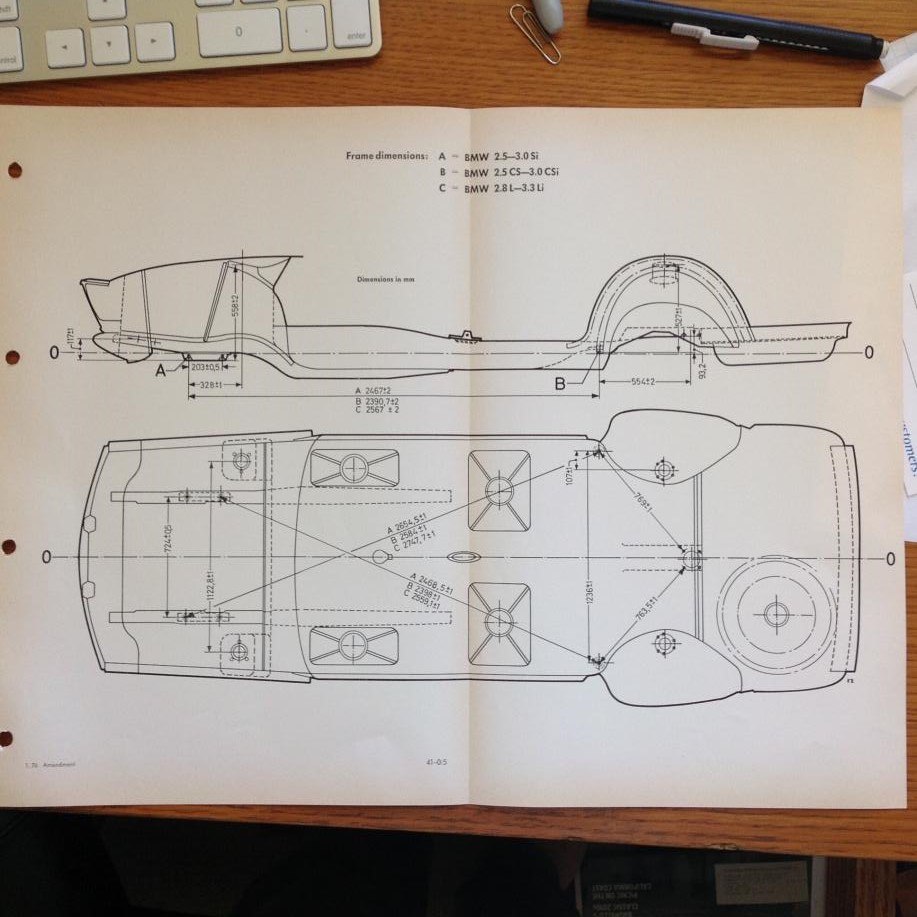

While laying out the precise holes in the dolly, I had forgotten my reference sheet (and computer) in the house. So I opened up my blue book and flipped to the fold out chassis dimension page. But I discovered that the chart in my blue book is different than the one I have digitally. Does anyone know what else might be "wrong" in my blue book? At the end, I might end up building the wrong car.

Digital chassis diagram that matches my car:

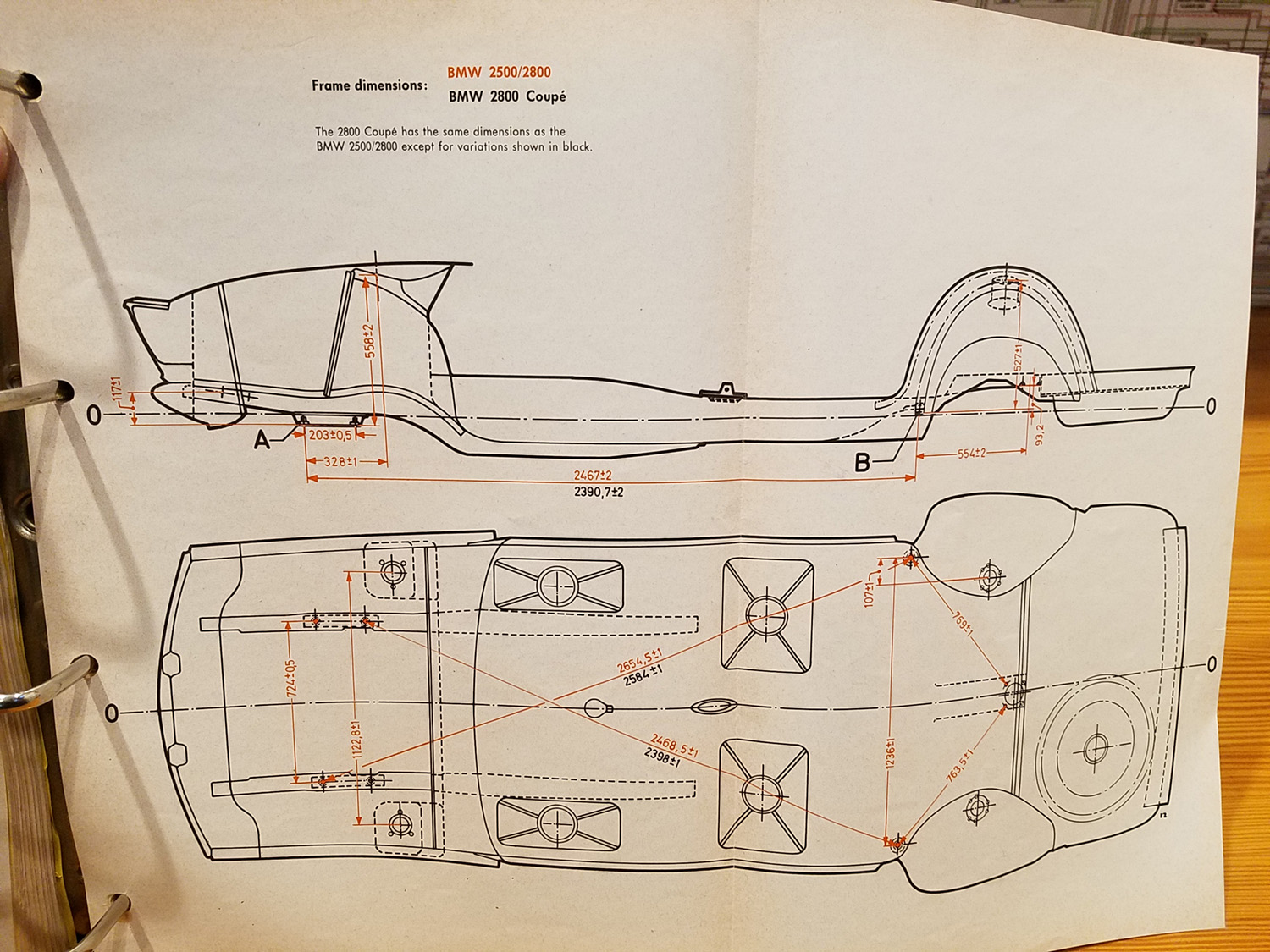

Diagram in the blue service manual I have:

My blue book cover/label:

79.25 hours

While laying out the precise holes in the dolly, I had forgotten my reference sheet (and computer) in the house. So I opened up my blue book and flipped to the fold out chassis dimension page. But I discovered that the chart in my blue book is different than the one I have digitally. Does anyone know what else might be "wrong" in my blue book? At the end, I might end up building the wrong car.

Digital chassis diagram that matches my car:

Diagram in the blue service manual I have:

My blue book cover/label:

I think your blue book has been hacked. Not cool!

I think that @autokunst and I subscribed to the same philosophy of learn as much as we can and hoard as many parts as possible to kick off the build. Being actievly engaged on the forum for the last (five!!!) years has really helped me understand many of the caveats of the car. @autokunst has been participating religiously as well. Stephen beat me to the punch on documenting hours. I intend to do this, and will continue to document spend as well. So far I'm all spend and no hours!

To add to what @m5bb mentioned about photos. I actually bought a amazon ripoff "go pro" with a headband mount and LED safety glasses. I intend to record the entire tear down process in HD. I purchased a bolt diameter/pitch/length gauge, and intend to narrate the size of every bolt quickly as I tear it down. The goal is to take no pics, and have the sizes for all bolts. I think this will help later when I ultimately hand stuff off to a zinc plating shop. I already have a very good handle on where everything belongs on the car, but particular things like the dash, doors and the motor have a number of bits to keep track off. I don't intend to publish the videos, but I'll cross that bridge when I get off my butt and perform the tear down. I did this recently with my camper restoration, and the thought of editing the content is a little overwhelming.

OCDOCDOCD.

OCDOCDOCD.

I’d feel more comfortable if you repeated once more. I struggle with odd numbers.

I am starting to wonder if I have an earlier publication of the book? Else, it would seem someone put the wrong cover cards in an old/different book and deceived me. I am too comfortable inside with a cocktail (Boulevardier) right now - but tomorrow I'll page through the book more thoroughly...I think your blue book has been hacked. Not cool!

Someone mentioned hours......

I have over 4000 hours in my coupe build reassembly from a rotisserie car to driveable. No detail was left unturned.

Many more hours scattered out tweaking things.

That does not include building the engine in 2014, removing it, doing improvements and re installing.

A labor of love or is it madness...

I have over 4000 hours in my coupe build reassembly from a rotisserie car to driveable. No detail was left unturned.

Many more hours scattered out tweaking things.

That does not include building the engine in 2014, removing it, doing improvements and re installing.

A labor of love or is it madness...

Last edited:

Ah, the Boulevardier, really means "Man about town" and you have just the correct car that deserves this moniker. Well chosen refreshment Stephen, enjoy!I am starting to wonder if I have an earlier publication of the book? Else, it would seem someone put the wrong cover cards in an old/different book and deceived me. I am too comfortable inside with a cocktail (Boulevardier) right now - but tomorrow I'll page through the book more thoroughly...

First diagram use ‘B’ the e9 measures, same as second diagram with Black measures.

Yes, I have the information need (and fortunately I've built the dolly to the correct measurements). It just startled me when it appeared my blue "bibles" may not be as relevant to my particular car model as I'd thought they were.First diagram use ‘B’ the e9 measures, same as second diagram with Black measures.

I feel this post is a bit incremental. But I've been super stressed about a) if the car will fit on the precise (blueprint) dolly points, and b) how dropping off the car at the dipping place works. So for the dipping place, I drove down there today. Turns out all I have to do is get the chassis there, and they will help be get it off the trailer, etc. I was worried I'd need to bring a "team". (I don't have a team).

There were some pretty cool cars there. An Alfa, a ZZ top looking car, and a few other american muscle hot rod cars that I didn't photograph.

But the better news is, the chassis slid down directly over the "blueprint" dolly points perfectly! She's rolling.

I still haven't solved the trailer. I was going to rent a U-Haul flat bed trailer, but I don't think it is big enough. It is only 12' long and has a front "railing" and the ramp folds up in the rear - limiting the length to a concise 12'. The car is every bit of 15' long, so I don't think this will work. I might try to call a flat bed, but worried that will be spendy. The place is about 16 miles away.

There were some pretty cool cars there. An Alfa, a ZZ top looking car, and a few other american muscle hot rod cars that I didn't photograph.

But the better news is, the chassis slid down directly over the "blueprint" dolly points perfectly! She's rolling.

I still haven't solved the trailer. I was going to rent a U-Haul flat bed trailer, but I don't think it is big enough. It is only 12' long and has a front "railing" and the ramp folds up in the rear - limiting the length to a concise 12'. The car is every bit of 15' long, so I don't think this will work. I might try to call a flat bed, but worried that will be spendy. The place is about 16 miles away.

I still haven't solved the trailer. I was going to rent a U-Haul flat bed trailer, but I don't think it is big enough. It is only 12' long and has a front "railing" and the ramp folds up in the rear - limiting the length to a concise 12'. The car is every bit of 15' long, so I don't think this will work. I might try to call a flat bed, but worried that will be spendy. The place is about 16 miles away.

Fantastic job on the dolly! I think you can use a 6x12 Uhaul utility trailer. The car is less than 6’ wide. The trailer code is “RO”, and has a short fold down door that you can leave open. You don’t want the ramp trailer (HO). The RO bed is corrugated steep so the dolly wheels will want to pick a channel and the car likely won’t shift much if the wheels align with the channels. The chassis only weighs about 550lbs or so. You can use your lift with some chains or (gasp) even the roof to drop it in the trailer. The trailer has sides about 30” tall.

I rent a LOT of uhaul trailers.

I vote flat bed. Experienced drivers, lash everything down, let you watch and comment. Gets there. What are you really saving?