I read a white paper that talked about the proper RH to store classic cars. It stated that you have to keep it below 20% to halt oxidation. That is my goal.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Raven e9 project

- Thread starter autokunst

- Start date

-

- Tags

- restoration list

Seems pretty good considering you live on the beach.That number is simply unreal. With two dehumidifier running 24 seven in my garage. I am lucky to stay at around 43 or 44%.

Willing to part with it, Chris?

Yes, I dug it out for you after seeing this thread. Will send it off shortly to the address we used for the tension strut transaction.

Consider it a thank you present for your help with my holophane project.

Consider it a thank you present for your help with my holophane project.

Eeeeee. < expression of joy.

Thank you Chris! You are very welcome and, of course, this is not necessary. But I'll gladly accept this cover.

Thank you Chris! You are very welcome and, of course, this is not necessary. But I'll gladly accept this cover.

I have been far too busy at work. Also, Stuart, the 1600, has been continuing to be a distraction. But I'm posting today to demonstrate proof of life. I have been inching forward on Raven.

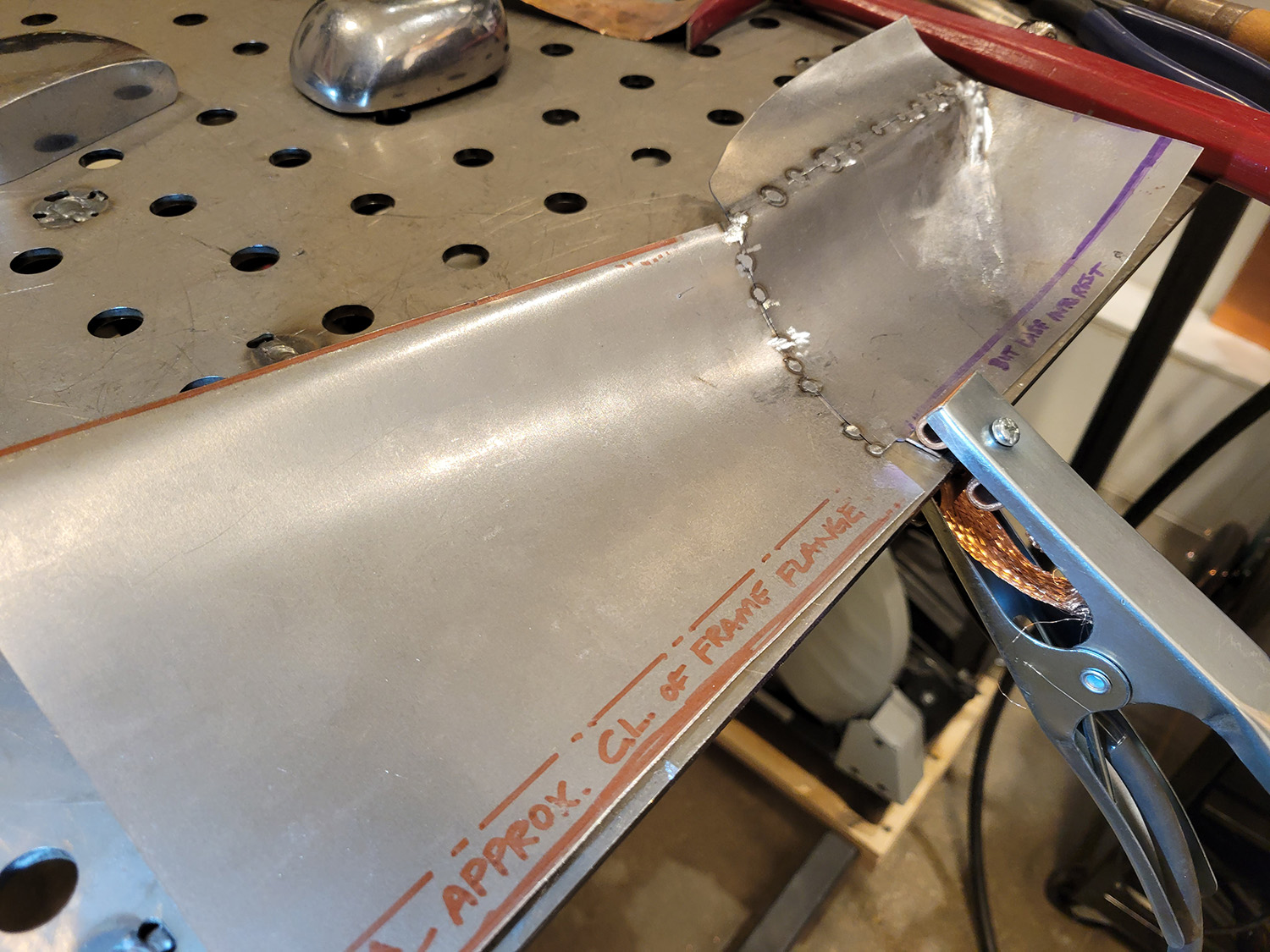

As previously discussed, none of the manufactured floor pans have all of the correct details. It seems the Polish panels are the most complete. But even those do not include the very complex shapes and compound curves that occur at the front left corner of the front right floor where the tunnel and floor meet. This is where there is a raised transmission mount on the underside and also additional clearance for the exhaust. Perhaps most floors are in good shape in this area, but mine had some corrosion that I wanted to address. This complex little shape had me baffled for a while. After a few attempts at trying to shape it out of one piece, I came to the conclusion that the shaping in one continuous piece off sheet metal was too complex for my skill level. I resorted to making it in a few pieces and welding it together. I realize it doesn't look like much yet, but it is a perfect fit and allows me to finally more forward on the front floor area.

I've decided that it is not worth spending the extra time to work these to a perfect metal finish. The top will be covered with padding and carpet, and the bottom will be covered with schutz. But I think the shaping came out well.

As previously discussed, none of the manufactured floor pans have all of the correct details. It seems the Polish panels are the most complete. But even those do not include the very complex shapes and compound curves that occur at the front left corner of the front right floor where the tunnel and floor meet. This is where there is a raised transmission mount on the underside and also additional clearance for the exhaust. Perhaps most floors are in good shape in this area, but mine had some corrosion that I wanted to address. This complex little shape had me baffled for a while. After a few attempts at trying to shape it out of one piece, I came to the conclusion that the shaping in one continuous piece off sheet metal was too complex for my skill level. I resorted to making it in a few pieces and welding it together. I realize it doesn't look like much yet, but it is a perfect fit and allows me to finally more forward on the front floor area.

I've decided that it is not worth spending the extra time to work these to a perfect metal finish. The top will be covered with padding and carpet, and the bottom will be covered with schutz. But I think the shaping came out well.

Rust in that area can be caused by a plugged a/c drain as the water accumulates and then splashes out when turning corners, perhaps more when making spirited left hand turns?

I have been far too busy at work. Also, Stuart, the 1600, has been continuing to be a distraction. But I'm posting today to demonstrate proof of life. I have been inching forward on Raven.

You know I was making a point that timeline are irrelevant when I named dropped you. This is coming from the slowest guy on the forum. It’s not just with the e9. You should see my home plumbing pace!

Of course. Hey, this forum is the only thing that keeps me at my current pace. Without the ability to share here, I would be far slower.You know I was making a point that timeline are irrelevant when I named dropped you. This is coming from the slowest guy on the forum. It’s not just with the e9. You should see my home plumbing pace!

My "around the house" projects have been at a standstill for years. It would be a complete embarrassment if I actually let anyone in the house.

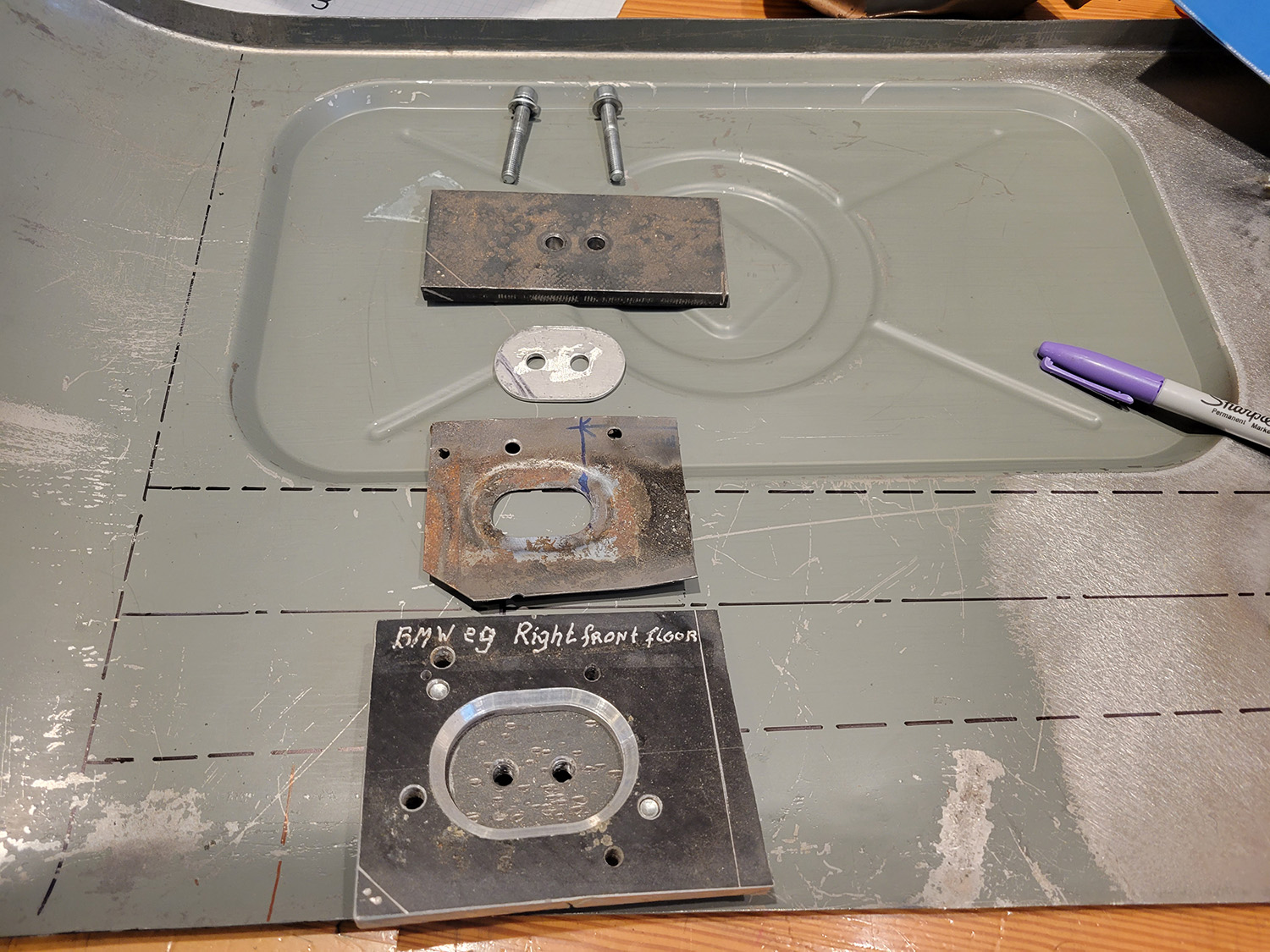

I'm continuing to work on the more complicated shapes where the floor meets the tunnel. But I wanted to share a detail and an offer from forum member @eriknetherlands

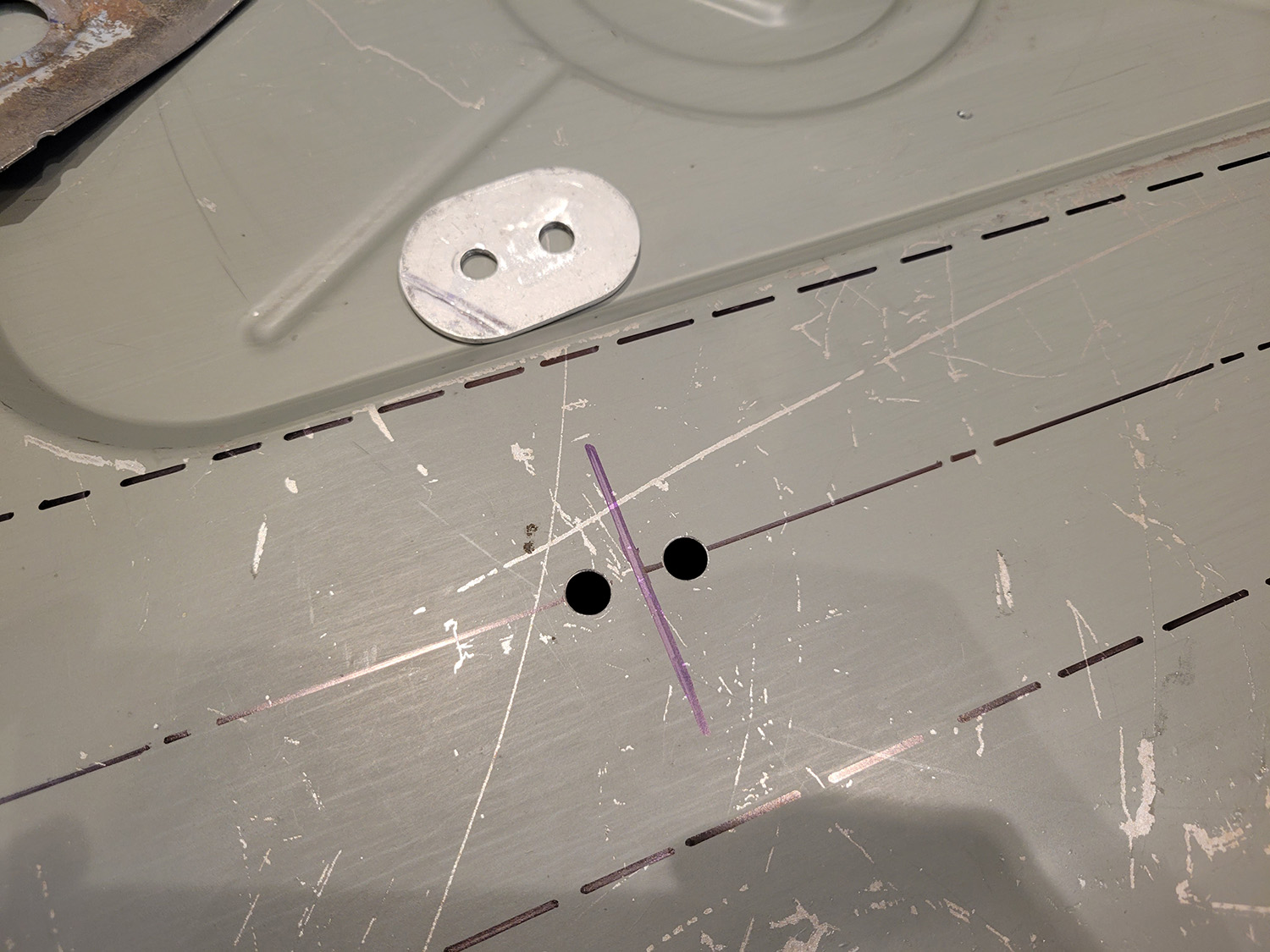

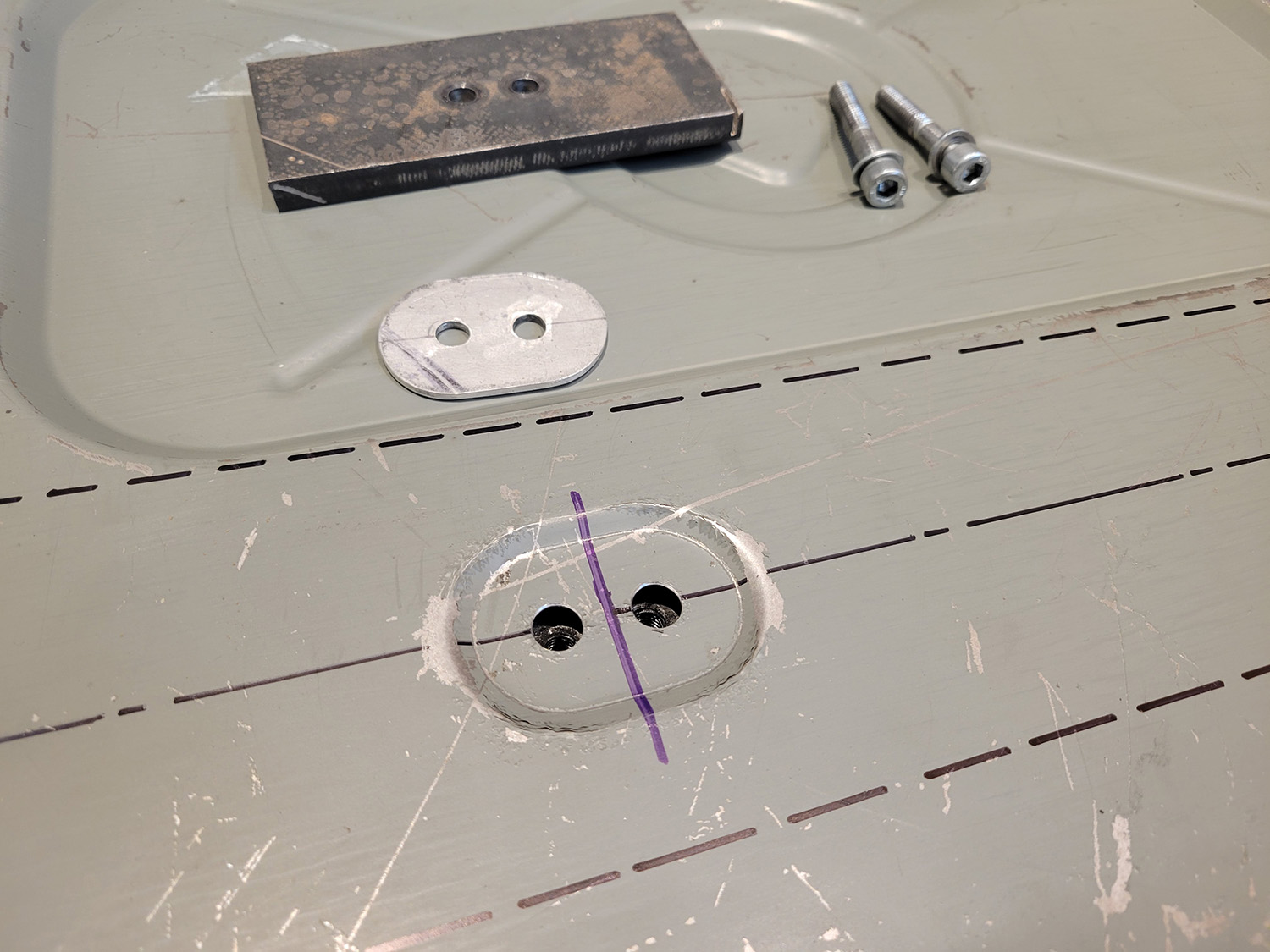

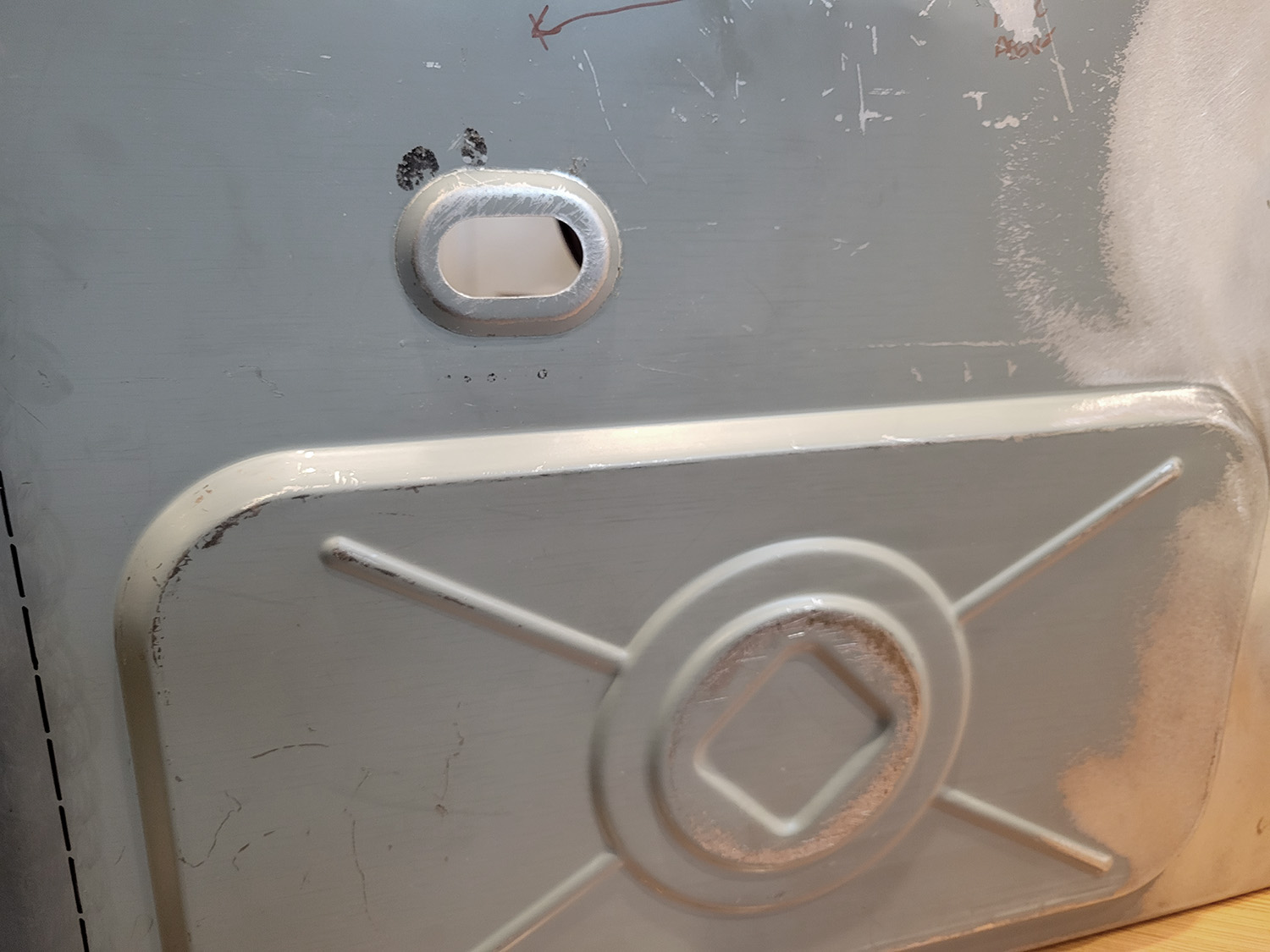

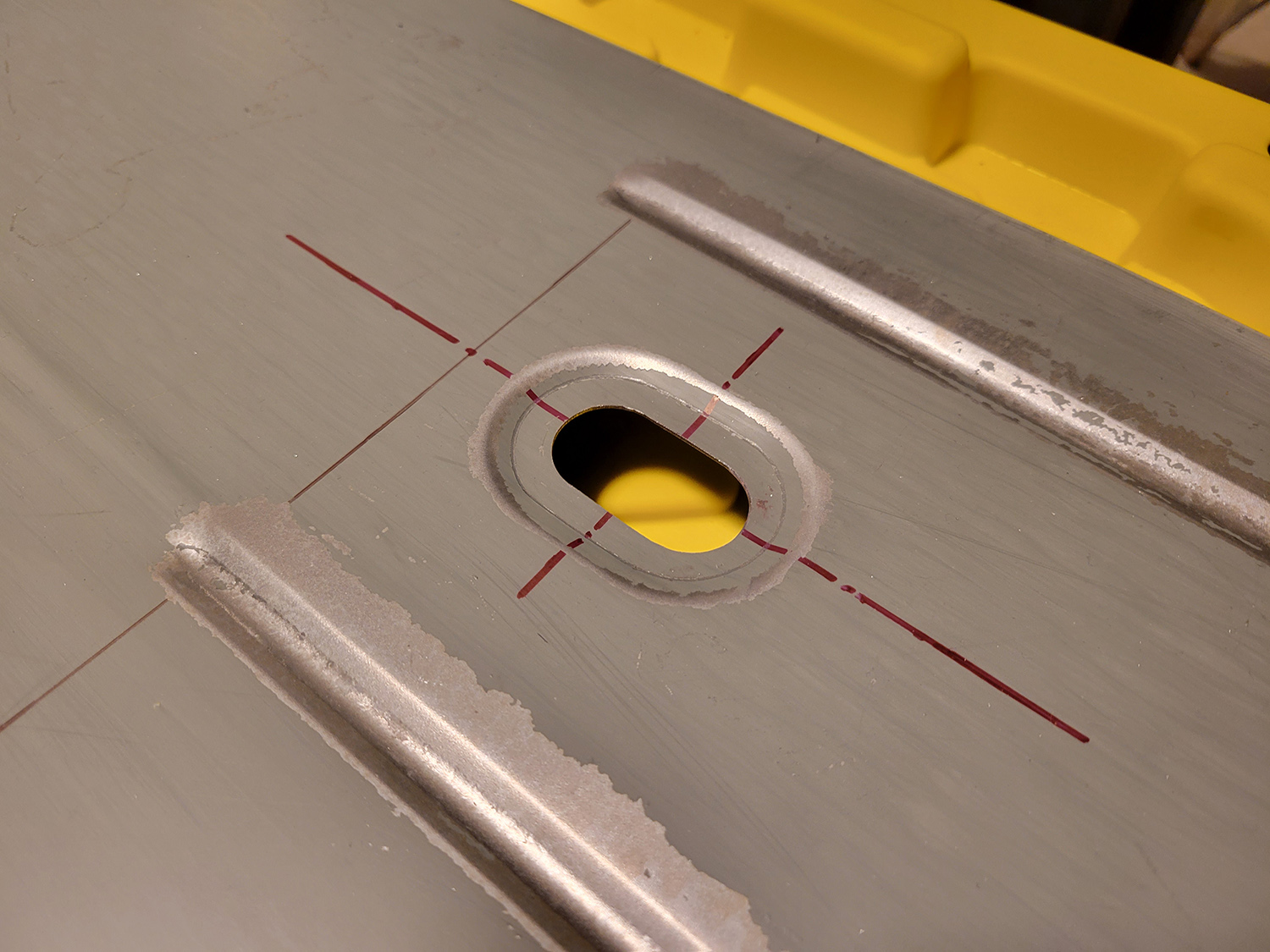

Erik was kind enough to send me his die for the oval plug dimples in the floor. These occur in three locations. The die worked very well, and I am pleased to have this small task behind me. When I told Erik I was ready to send them back, he suggested I make them available to anyone else in the US first. So feel free to let him or me know that you if you need to press some ovals.

Here is an overview of their use:

Erik was kind enough to send me his die for the oval plug dimples in the floor. These occur in three locations. The die worked very well, and I am pleased to have this small task behind me. When I told Erik I was ready to send them back, he suggested I make them available to anyone else in the US first. So feel free to let him or me know that you if you need to press some ovals.

Here is an overview of their use:

Nice work, nice tool. I will probably need something like that for my right side floor, but that's a long way in the future for now.

Nice to see the press tool being used!Nice work, nice tool. I will probably need something like that for my right side floor, but that's a long way in the future for now.

Honored that my diy attempts to make the tool are good enough for you guys; it's appreciated.

@mulberryworks; you could consider already purchasing the floor panel, and pressing in the oval depression. Then just chuck the panel in a corner of your garage untill the time comes to weld it in.

I think the location of the oval is fixed relative to the drain hole, so measuring out where it should go and pressing it in can be done "off-car".

Ah, the thought of having a free corner to store things for later inhabits my dreams, but not my reality. Our move to a slightly smaller house means that all available storage is used and things have to shuffled for access on a regular basis. The 2800CS is surrounded on all sides by containers & equipment with inches to spare but no room to work or even open the doors.@mulberryworks; you could consider already purchasing the floor panel, and pressing in the oval depression. Then just chuck the panel in a corner of your garage untill the time comes to weld it in.

I think the location of the oval is fixed relative to the drain hole, so measuring out where it should go and pressing it in can be done "off-car".

I've been delayed again on my new garage build as the one-man shop I chose to complete the required drawings was busy, then got COVID and though he has promised to deliver preliminary drawings "tomorrow" for over a month, he's stopped responding to inquiries. So two and half months of waiting are down the drain and a new company must be engaged with their own queue for service. Hence, my estimate that I won't need a dimple tool for quite some time.

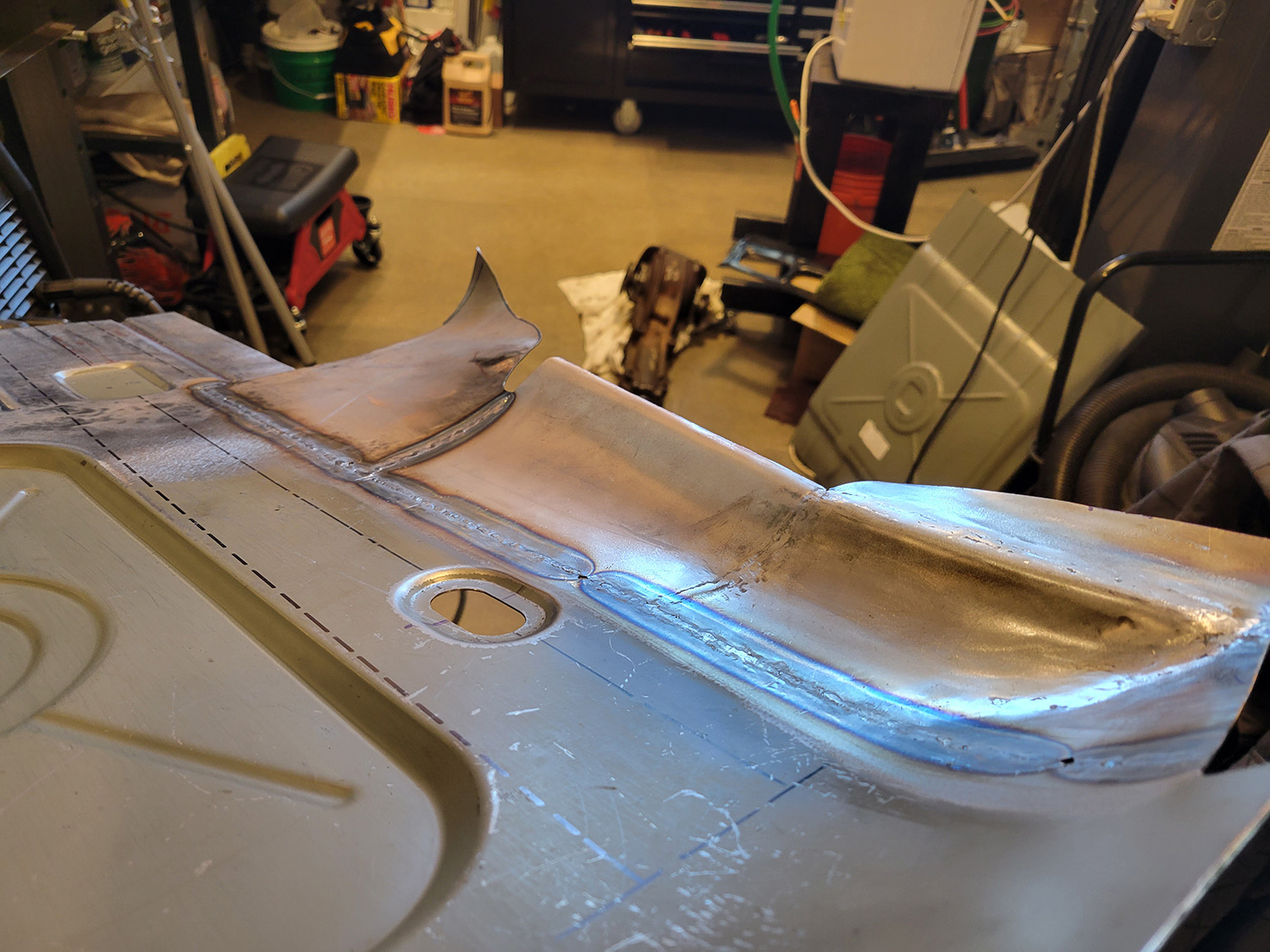

A little bit of welding on that complex floor area where it joins the tunnel. Getting closer...

One of the tricks with TIG welding thin sheet metal is to put a consistent amount of heat in it. It will always distort as it cools, but if the heat is consistent, it is relativly easy to hammer and dolly out the weld to stretch it back out to its original shape (whereas if you get it very hot in one area an not so much in another, the differential distortion is hard to chase back to the proper shape).

I am pretty pleased with the heat signature here.

And I love seeing this shape work with the floor.

One of the tricks with TIG welding thin sheet metal is to put a consistent amount of heat in it. It will always distort as it cools, but if the heat is consistent, it is relativly easy to hammer and dolly out the weld to stretch it back out to its original shape (whereas if you get it very hot in one area an not so much in another, the differential distortion is hard to chase back to the proper shape).

I am pretty pleased with the heat signature here.

And I love seeing this shape work with the floor.

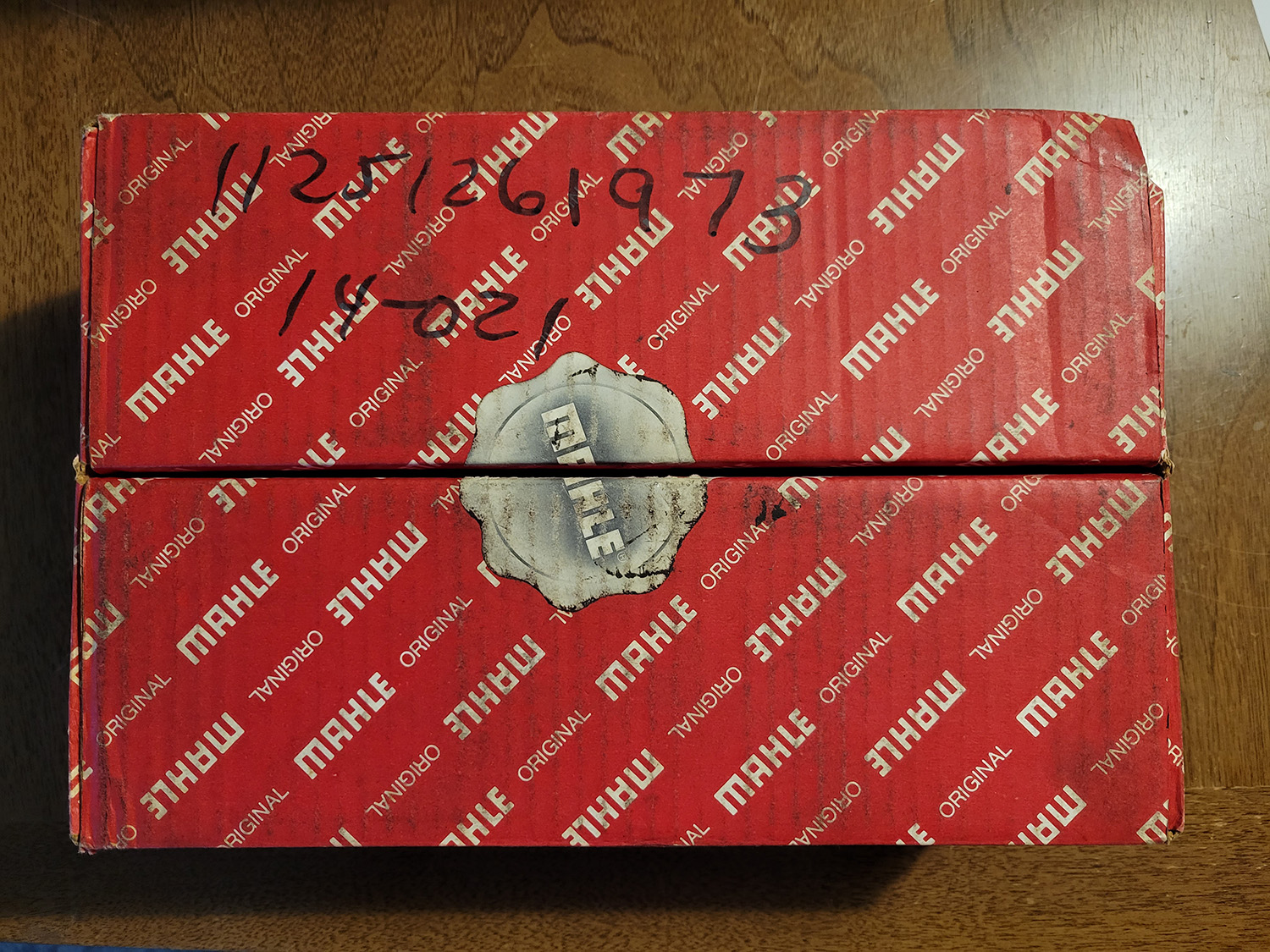

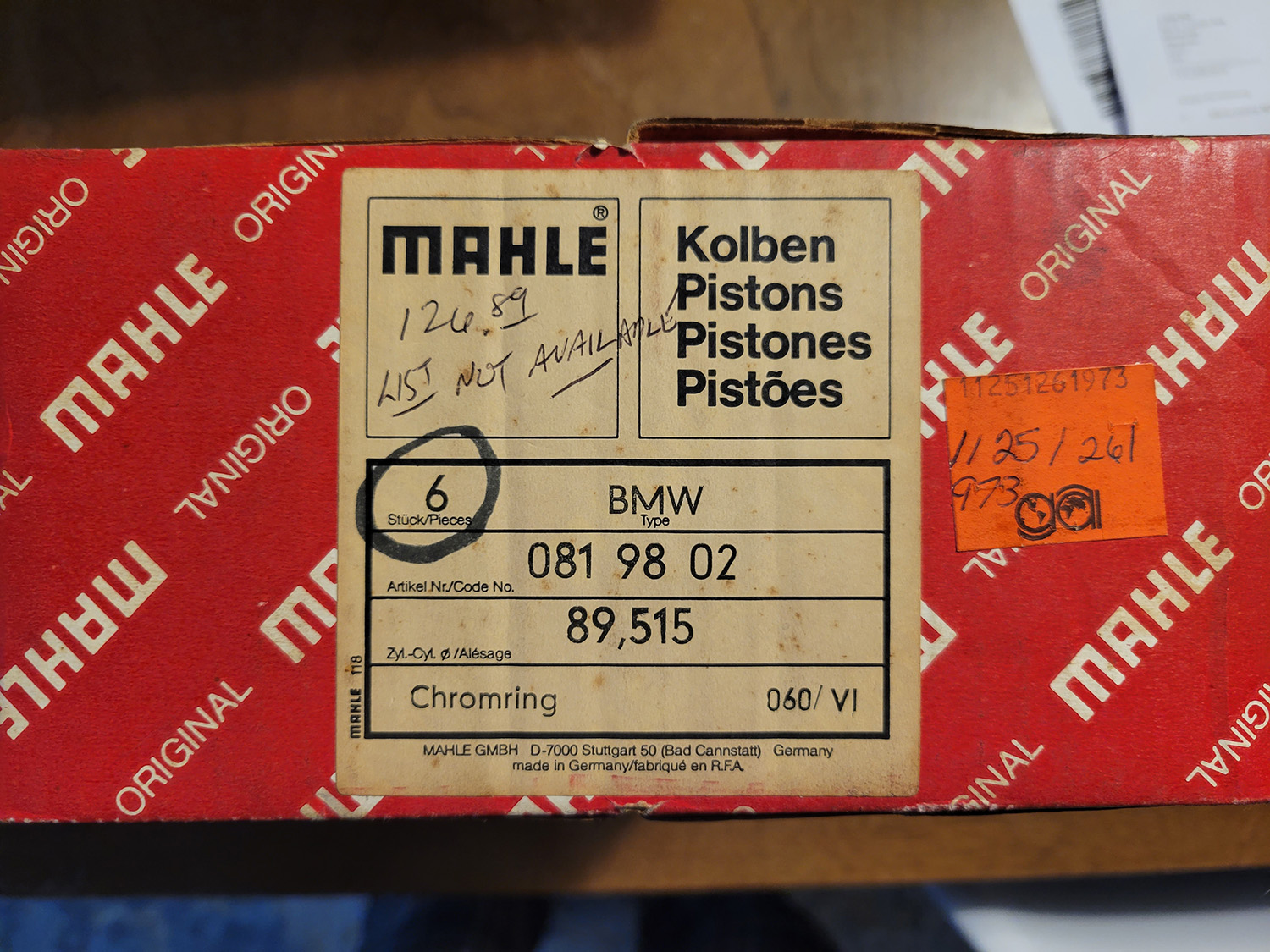

Writing today to share my newest purchase: "euro high compression pistons", or, piano top pistons. These are the second overbore diameter. The seller referred to these as 9.5:1 compression, although I think BMW referred to the associated engine as 9.2:1 (I'm no expert, so please feel free to educate me). Perhaps a slight shave of the head and/or a thinner head gasket would squeak a few tenths out.

Although I still have a mountain of chassis work before me, many of you know I love a distraction. I am thinking about starting the build the engine (on the side). This would include a running engine stand so I could test the engine and run it from time to time while I continue to work on the chassis. I call that motivation! If I go forward with this project I will start a separate engine build thread.

Look at that beautiful patina'd box.

Each wrapped in a heavy wax paper. It's better than a box of donuts!

The piano.

Is this a date code?

Although I still have a mountain of chassis work before me, many of you know I love a distraction. I am thinking about starting the build the engine (on the side). This would include a running engine stand so I could test the engine and run it from time to time while I continue to work on the chassis. I call that motivation! If I go forward with this project I will start a separate engine build thread.

Look at that beautiful patina'd box.

Each wrapped in a heavy wax paper. It's better than a box of donuts!

The piano.

Is this a date code?

Wow those look amazing!

If things on your engine don't turn out to be something simple (still hoping...), I wish we lived closer to each other. We could build engines side by side.Wow those look amazing!

I would just rebuild the motor and leave it on a stand, you could turn it over by hand every month or two. Just trying to help you keep your focus on your build!

I'm not sure if I'm the right guy to give tips on speedy resto's....

Nice find on the pistons!

I you ever come to the conclusion that you do not need them, can I take dibs?

Nice find on the pistons!

I you ever come to the conclusion that you do not need them, can I take dibs?