Almost forgot another topic. I also removed the rear seat riser and left side gusset. This will make patching the speaker holes and any corrosion patches much easier and better. This assembly of three pieces (riser and gussets on each side) appear to provide some bracing/stability to the inner sill and B-pillar. But the sheet metal is thin and is not attached very robustly. In fact, there are two factory mig welds at the top of the tunnel to the riser, and one of mine had cracked, the other showed stress.

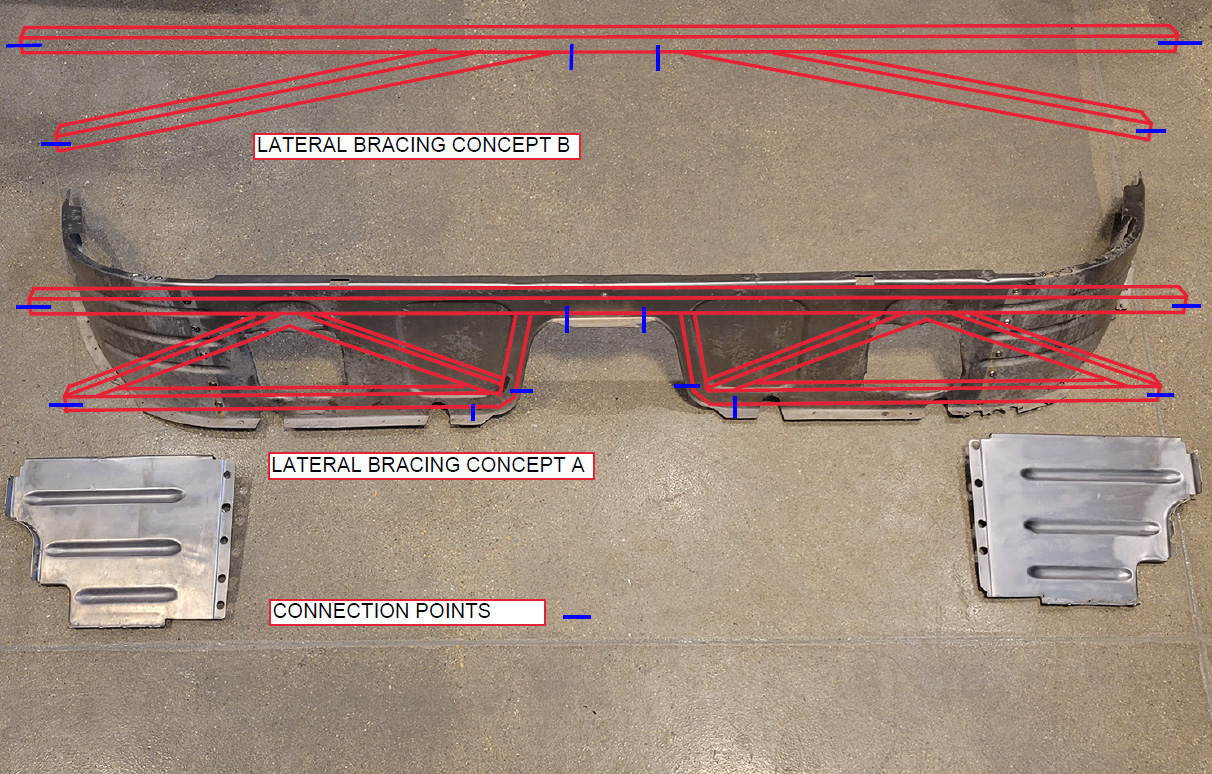

I don't want to add much weight, but I wonder if making a tube brace of some sort would add noticeable stiffness to the chassis. This would be entirely behind the sheet metal pieces and would not be visible in the car (unless you removed the rear seat). I am showing two versions in the following sketch. A third would be to tie this assembly back to the chassis points. Thoughts?

I don't want to add much weight, but I wonder if making a tube brace of some sort would add noticeable stiffness to the chassis. This would be entirely behind the sheet metal pieces and would not be visible in the car (unless you removed the rear seat). I am showing two versions in the following sketch. A third would be to tie this assembly back to the chassis points. Thoughts?