Definitely don't need the chokes as Barry mentions, but no matter what the temperature is you'll have to feather the idle with your foot until it warms up and holds idle speed on its own.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Raven e9 project

- Thread starter autokunst

- Start date

-

- Tags

- restoration list

Had a chance to cut and install the new foam piece for the cover, and I've placed the "refurbished" tool holder into the refurbished clam shell. I am not happy with the tool holder - it is actually two halves from different holders re-joined. It is not perfect, and I will have trouble sleeping with it like that. But it is not lost on my that I've spent an inordinate amount of time on this tool case and I have NO tools. :eek: I did see a complete tool kit on German eBay, but that is far too rich for my blood... And I still need to re-chrome the latch handle.

I may have to put this on a shelf for awhile and focus my energy elsewhere.

I may have to put this on a shelf for awhile and focus my energy elsewhere.

Last edited:

Just to show that I am making some progress (slow, methodical, but still progress), here are some shots of the rear fog light refurbishment part way through. I still need to tackle the metal parts, and either refresh or replace the gaskets. Anyone know if the gaskets are available separate from new assemblies?

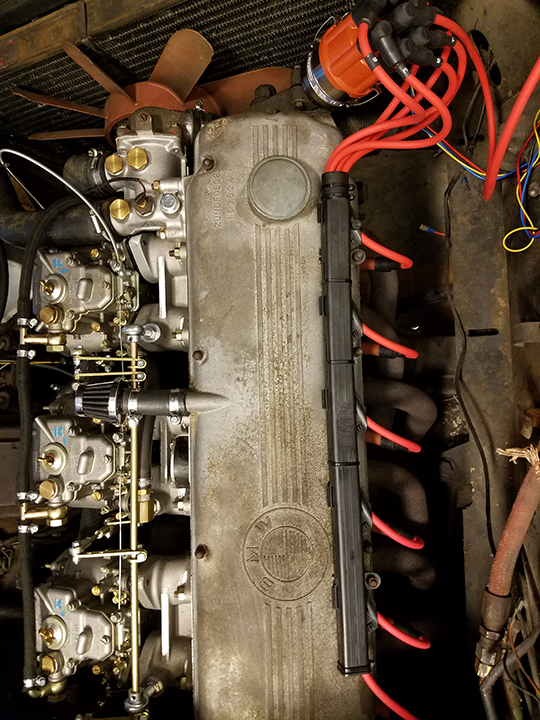

Slow and steady. I've been playing with the ignition and the carb tuning a little bit. That is the 123Ignition, and new Kingsborne wires.  Still have a long way to go, but it is getting better...

Still have a long way to go, but it is getting better...

Also, I discovered I still have the little orange port cover. It was just nestled between some bits behind the port itself. It is a miracle it didn't find its way to the road shoulder.

Also, I discovered I still have the little orange port cover. It was just nestled between some bits behind the port itself. It is a miracle it didn't find its way to the road shoulder.

Cleaned up the trunk bin. It is not perfect, but it will effectively hold items from sliding around the trunk.

Question: Were the bins attached to the floor panel to keep it in place? I see three holes in the bottom of the bin which could easily have been a way to attach it to the floor. Or did they just sit there by virtue of friction?

Question: Were the bins attached to the floor panel to keep it in place? I see three holes in the bottom of the bin which could easily have been a way to attach it to the floor. Or did they just sit there by virtue of friction?

Screwed to floor board, screws used a cup washer as well.

If you take the white trim pieces off and spray it inside and out with SEM storm grey it will look new(ish)

Stephen what did u use to fix the broken ears on the tool kit? The part on top with 2 screws that mount it into the trunk? Both of mine have the ears busted off. was going to try epoxy putty but yours looks clean.

I have to admit, I am a little frustrated in myself with this trunk bin project. I didn't have one, so I picked this one up from another member. We worked together on an acceptable price, but in reality I now believe I over paid for this bin. My frustration is NOT with the seller. I went into this heads up. Rather, it is mostly with BMW - this bin is nothing more than some chipboard cut into a shape and riveted together. That it lasted this long is a miracle. But once the "faux leather skin" on the chipboard gets scuffed, torn, or scratched, it is permanently damaged.If you take the white trim pieces off and spray it inside and out with SEM storm grey it will look new(ish)

The bin I show above has been cleaned up, white strips removed, thoroughly prepped and sprayed with SEM warm grey (rivets masked off before spraying), and then put back together. The paint just soaks into the exposed chipboard. After all of that work, it does not meet my own expectation of level of finish. So I now have a fair amount of $$ and time into what I feel is a decent template to make a new one of these from scratch. And all for an interior trunk detail that will help the car return to its original trim. :eek:

Hello Ajay,Stephen what did u use to fix the broken ears on the tool kit? The part on top with 2 screws that mount it into the trunk? Both of mine have the ears busted off. was going to try epoxy putty but yours looks clean.

I had to rebuild the two corners of the shell, and also repair a couple of other minor areas. I had a second clam shell that was in worse condition. I started by prepping the jagged edges of the corners by removing any loose or partially cracked sections. Then I cut filler pieces from the other shell that closely matched the missing pieces (almost like a puzzle) to bond into the target shell. I abraded the area well, and epoxied the repair pieces onto the shell, filling all voids and fairing out. Some of the areas took more than one application, always re-prepping the area for good bond. Once everything was bonded and built up, I sanded everything flat and smooth and prepped for the paintwork (SEM warm gray). I was/am concerned about the long term strength - after all, it is still 45 year old plastic. That's why I then bonded a layer of fiberglass cloth on the back side with epoxy. This is a boat building method, only I used a thicker epoxy here so the fiberglass didn't wet out like it does on a boat. But I think it is holding very well. Sorry, I don't have pics of the repairs in progress.

I do still have to drill for attachment to the deck lid. I plan to wait until I have the upper panels and deck lid all ready so everything aligns perfectly.

Thanks Stephen. Very helpful. I am doing a similar repair while using the powder +super glue then sanding and preparing to paint. I need to find a donor piece of plastic or some ears for the tool kit to do the surgery.

Belgiumbarry

Well-Known Member

that (was) is indeed a silly bin , not BMW worth . I hope they fired at least that engineer

I'd be happy to send you some pieces of the tool kit plastic for you to use if you'd like/need. I still have quite a bit of my donor shell. Let me know.Thanks Stephen. Very helpful. I am doing a similar repair while using the powder +super glue then sanding and preparing to paint. I need to find a donor piece of plastic or some ears for the tool kit to do the surgery.

Indeed! I was thinking about making one out of heavy leather. It sure would be rewarding after playing around with this chipboard piece for a while. My only hesitation is that I'd want to take apart/open up the original one to use as an accurate template. But I don't think that will be too much love loss.that (was) is indeed a silly bin , not BMW worth . I hope they fired at least that engineer

The repair made famous by Murray aka Blue Max was to cut small pieces of Aluminum and adhere with JBWeld on the backside, then fill in the missing plastic with more JB. When cured dremel and sand then paint.

Hi Chris,The repair made famous by Murray aka Blue Max was to cut small pieces of Aluminum and adhere with JBWeld on the backside, then fill in the missing plastic with more JB. When cured dremel and sand then paint.

That is not terribly dissimilar to my repair. Only instead of aluminum, I used fiberglass bedded in epoxy (JB Weld). It is great to know I'm not the only one that finds this method beneficial.

Speaking of JB Weld, have you ever read the verbiage on the packages? They are little example stories, like: "A farmer in Nebraska used JB Weld to fix his sheep shear." I have long wanted to get added to the package: "An architect in Wisconsin used JB Weld to repair his e9 clam shell."

Thanks Chris. I will try anything at this point. You may not remember but we met a few months back at Mike P's old place in Costa mesa when I was admiring your beautiful coupe. You & I have a common friend in the Los Alamitos area. That friend has helped me immensely on my car. Great guy.The repair made famous by Murray aka Blue Max was to cut small pieces of Aluminum and adhere with JBWeld on the backside, then fill in the missing plastic with more JB. When cured dremel and sand then paint.

... or repair a broken float tab on his Weber DCOE top cover plate.." I have long wanted to get added to the package: "An architect in Wisconsin used JB Weld to repair his e9 clam shell."

We should start a thread entitled "Stuff I've fixed on my e9 with JB Weld"