So here is a quick little one that was first mentioned by another forum member (in the UK IIRC) whose name I have sadly forgotten. But all credit goes to him for this one.

I found it! The originator of this idea was @Rek

Last edited:

So here is a quick little one that was first mentioned by another forum member (in the UK IIRC) whose name I have sadly forgotten. But all credit goes to him for this one.

Also commonly referred to as "backer rod". Brilliant idea.Correct. Round cross section. Size is labeled here as 1/4 inch. Matches actual measurement pretty good at 6.3 mm

View attachment 199911

Great to hear from you @Rek With the one I used (yes it is closed cell of course) I did not have to glue the ends. And I definitely did test them at high speedThank you for the credit. I used 10mm diameter but ensure it is closed cell meaning that water cannot penetrate. I trimmed the ends and glued them with contact adhesive, otherwise they fly off at higher speeds.

This is great.The countdown to Monterey 2025 has started. As such it is time to attend to a large number of seemingly small items on the list.

First I was faced with the dreaded broken horn pin syndrome. Those things were never that strong to begin with but being a tall skinny thing held by two screws at the bottom makes it a good candidate for beheading. Especiallyif you have to remove and reinstall the steering wheel frequently as you do when doing lots of work on and around the dash.

View attachment 206222

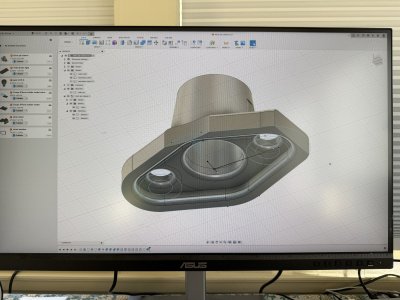

Instead of buying yet another new one, I decided to epoxy this one back together and then design and 3D print a little “exoskeleton” to beef it up

View attachment 206229View attachment 206229 View attachment 206224 View attachment 206225

This then slips over the existing pin and acts as a strong reinforcement

View attachment 206226 View attachment 206227 View attachment 206228

'