I am reviving this thread as I am now battling this issue. My theory (besides the crank pressure one as noted above) is high oil pressure and I am asking the experts to confirm or debunk this possibility.

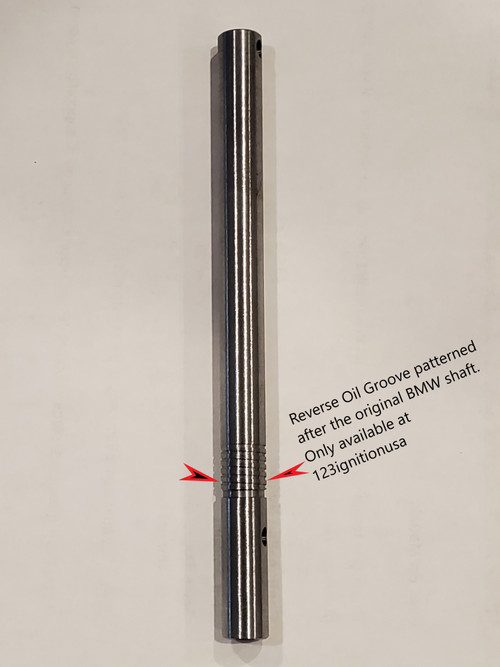

When I rebuilt my engine, the oil pump was also rebuilt and it works great. Hot oil pressure maxes out about 60psi at 4k rpm or so and 22 at idle. But after the engine had broken in and been running for a while, I noticed the dreaded oil seepage between the sandwiched circuit boards and oozing out of the cap. I removed the 123, cleaned the circuitry, and installed a new seal and bronze bushing. I already have the helical groove "upgrade" shaft - which now obviously isn't enough to hold back the oil. Yesterday, 6 weeks later, I noticed the issue is back after only a thousand miles or so.

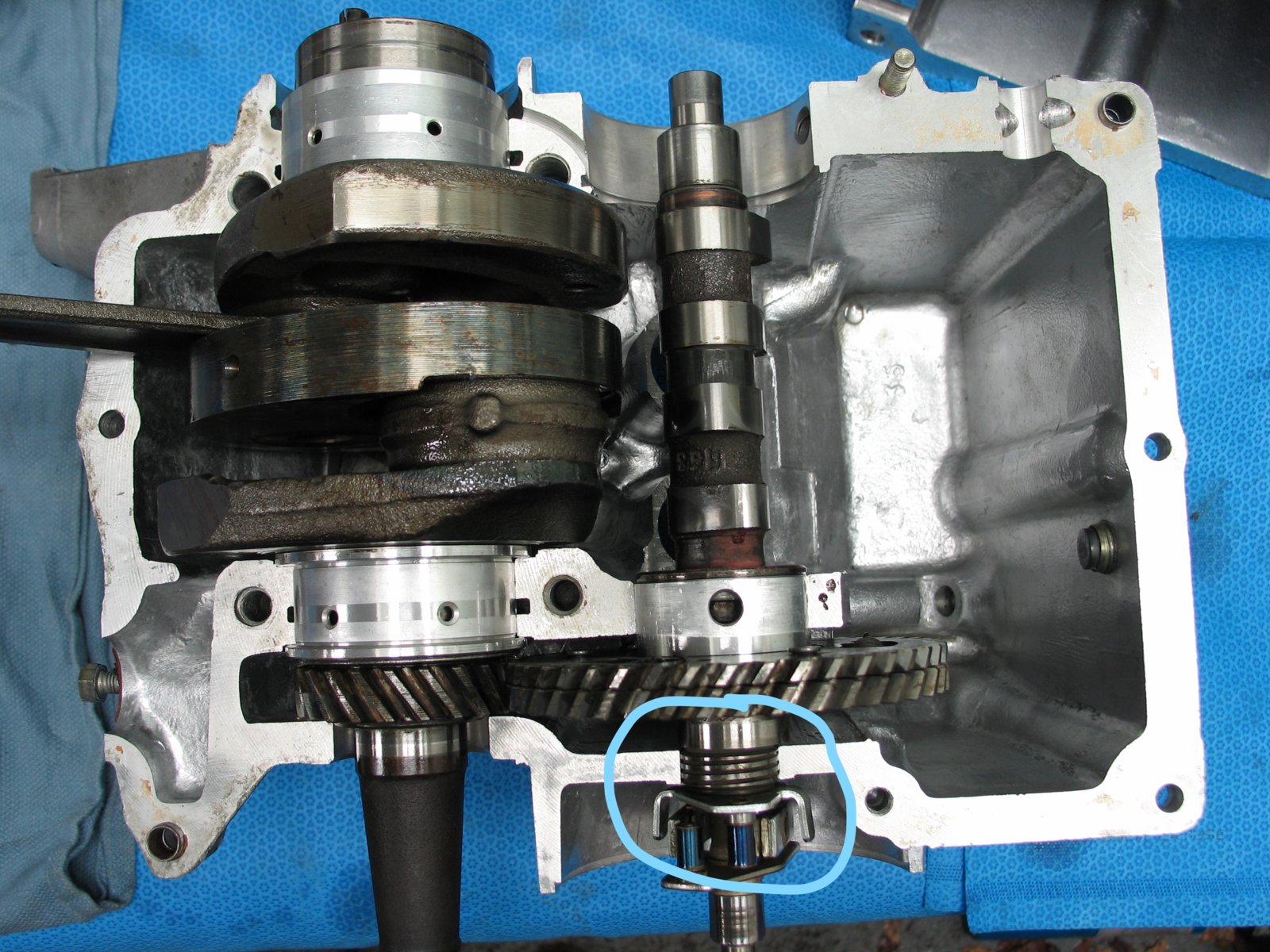

My suspiscion started after the engine rebuild and before starting for the first time. I spun the engine with the starter (no plugs) to see if I had any oil pressure and if so, build it up before the first real start. I did this without the distributor in place and when I cranked it, oil shot out of the dizzy hole across the garage - not a drizzle, a significant shot that cleared the fender. I noted back then that if I ever had 123 oil intrusion that this may be the source. So here we are.

In summary:

1. I have the grooved drive shaft

2. I have new a bronze bottom bushing and shaft seal (looks like a mini transmission selector rod seal)

3. I have oil seeping before and after the latest 123 rebuild.

4. I have the valve cover breather hole venting with no restriction (other than the diameter of the hose attached to the fitting - hmmmm.....).

5. The only thing that has changed is the engine rebuild with higher compression pistons (10:1) and oil pump rebuild

Therefore, if it is the crank pressure:

1. High revs and/or high compression pistons overpower the ability of the valve cover hole to vent, possibly with, certainly without vacuum from the stock air cleaner, thereby driving oil up the 123 shaft past the groove and seal. Interestingly enough, I have little to no condensed oil at the bottom of my valve cover vent tube so a large amount of blowby is not evident. I may try a larger diameter hose but I suspect this will not have any effect.

If oil pressure:

1. High oil pressure, especially cold 20W50, drives oil up the 123 shaft past the groove and seal

Any thoughts on the above? I love the tech of the 123, and given BMW is the only engine with this issue as far as I can tell (I've searched other forums), I'm not ready to fully blame the 123. Yet.

I'll be cleaning this again AND thinking of a possible fix.