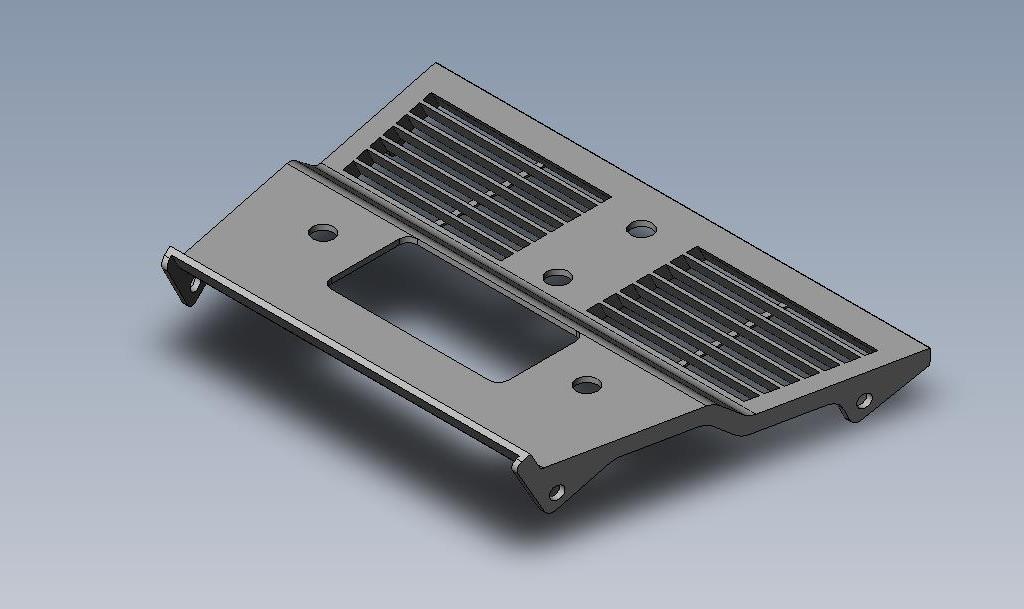

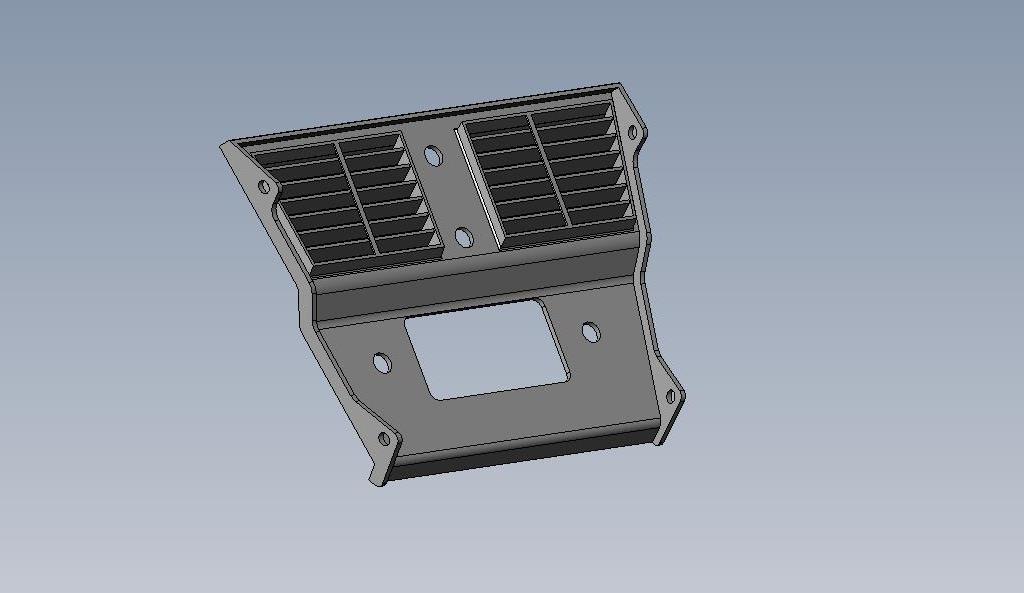

Before selling my AC Setup, I decided to send the E9 face plate out to a SolidWorks modeler to recreate. The part is in the mail and I should have a draft design by the end of next week.

I called for three designs. One with the standard radio opening, one that is blank, and one that has three gauge holes. The blank one may have lines in the back to facilitate the cut out of the radio on the future. I haven't checked if gauges will fit the space yet. My CSI was a rats nest of stereo wires in that area.

I intend to print with a professional 3D printer, and sell them with a markup to

cover the cost of the modeling. A BMW friend of mine runs a PolyJet printer, and has numerous printing contacts in the Seattle area. Technically they could be printed with powdered aluminum, perhaps for the concours crowd.

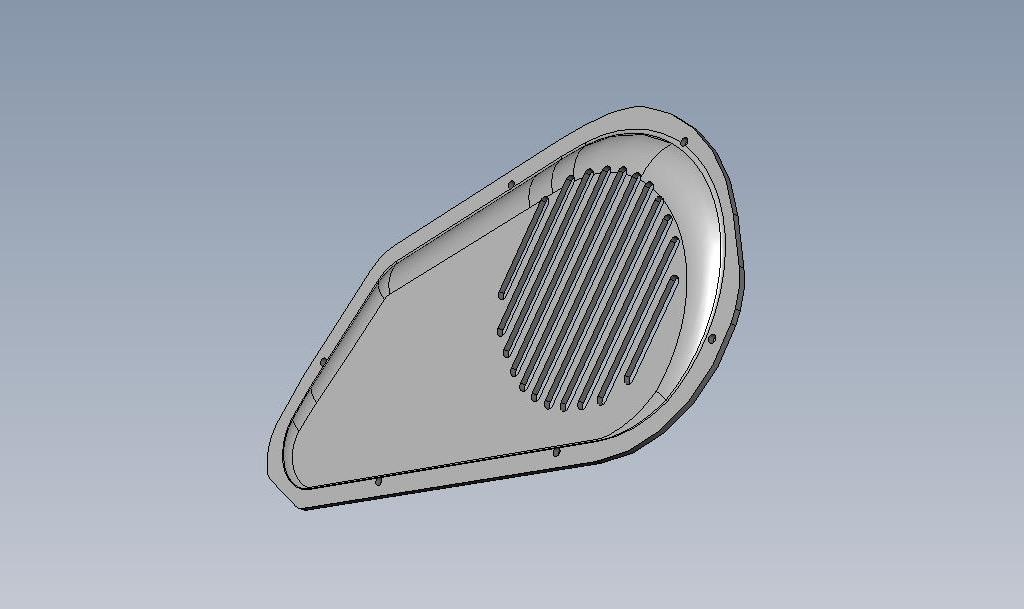

Oh - I also sent the AC grills. I haven't paid for those yet, but I will likely have them modeled also. I would imagine that those are much easier to sell.

Keep you posted!

I called for three designs. One with the standard radio opening, one that is blank, and one that has three gauge holes. The blank one may have lines in the back to facilitate the cut out of the radio on the future. I haven't checked if gauges will fit the space yet. My CSI was a rats nest of stereo wires in that area.

I intend to print with a professional 3D printer, and sell them with a markup to

cover the cost of the modeling. A BMW friend of mine runs a PolyJet printer, and has numerous printing contacts in the Seattle area. Technically they could be printed with powdered aluminum, perhaps for the concours crowd.

Oh - I also sent the AC grills. I haven't paid for those yet, but I will likely have them modeled also. I would imagine that those are much easier to sell.

Keep you posted!