this is simply extraordinary

thank you markos

thank you markos

Hi Patrick,

Similar to Stan's endeavor this isn't a money making effort for me. However, I am hoping to recover the investment costs I incurred having the parts designed.

I can load the models onto shapeways and cut myself out of the distribution process. I can also load them up to a similar site in Europe and Australia. These parts aren't "injection molded in China" inexpensive, so I'll have to keep the markup very low.

I'm checking on options and pricing to continue to print these locally. The printer used for the mockup is a very very nice unit. I may be able to print more with the same printer, which will save money and result in a better product.

the good news is that these guys respond quickly. but overall i am very impressed with the quality that both Stan + Mark have been able to have produced for us.It is a fun process isn't it :smile:

Markos,

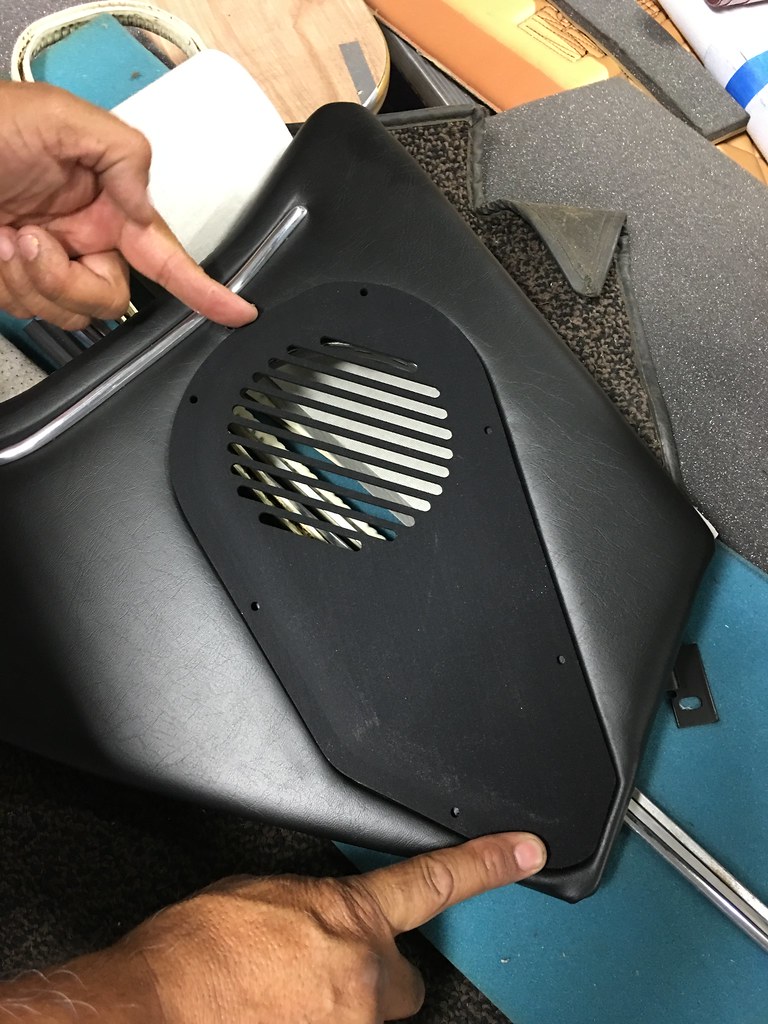

The e9 vent grille is chopped otherwise it extends beyond the side panel. The e3 side panels are longer and don't have the chop. I have both cars and have examined them closely.

Chris

Let me know if I can help out with adding the textures. I run a large digital design firm that loves these types of projects!