Maybe post in the PARTS Section with the current price and re-state that it would likely go down with volume. Then ask who is in.Thanks Scott!

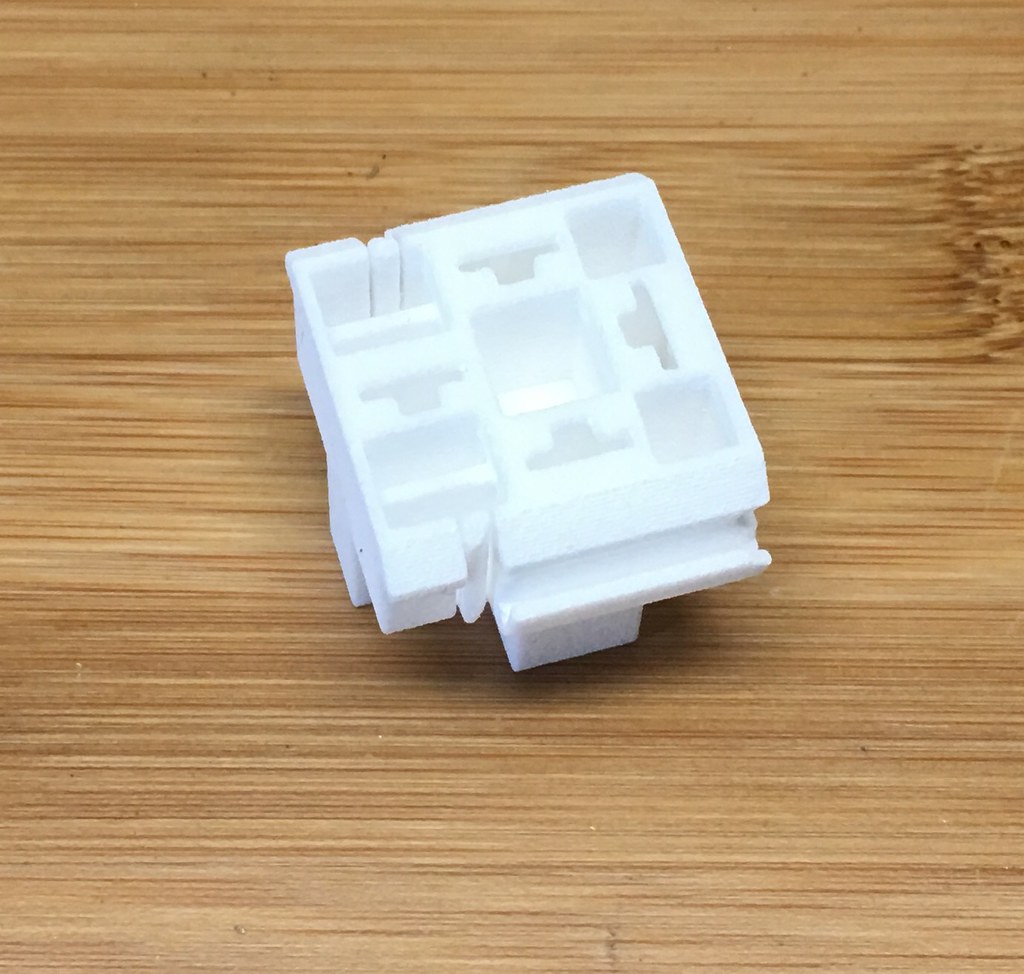

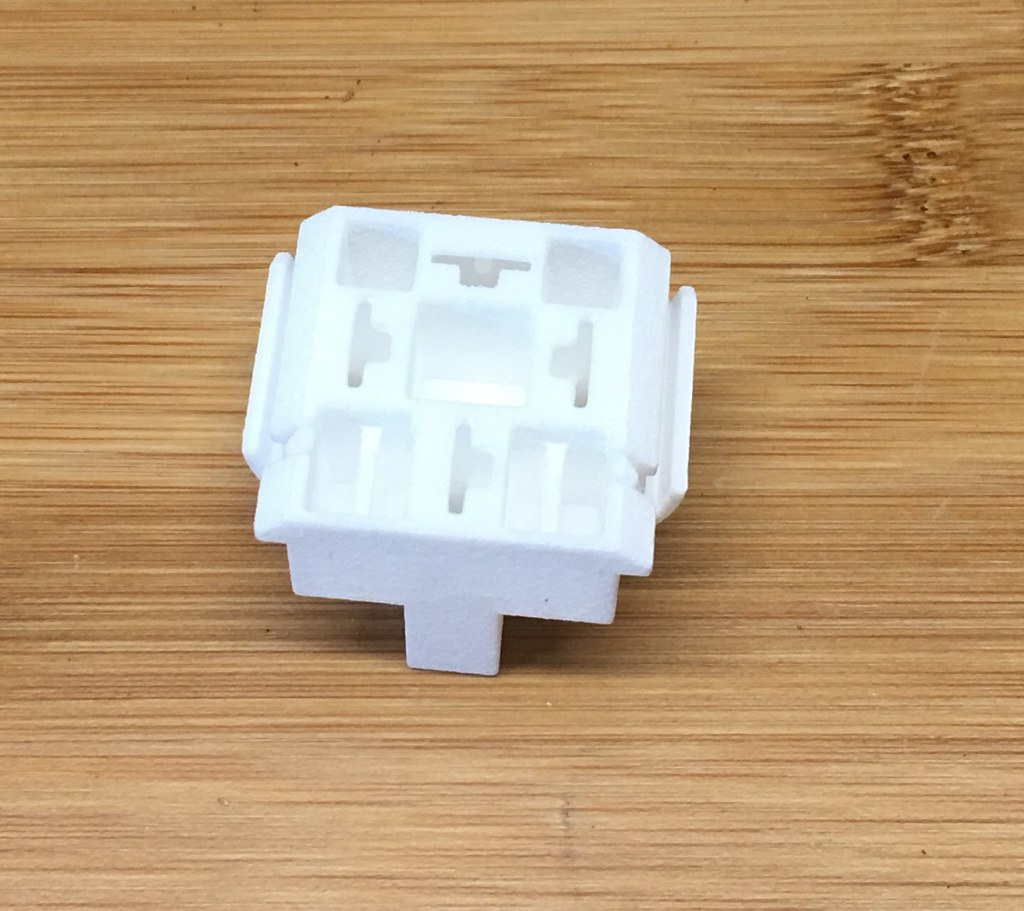

FYI - If I print these in bulk the price goes down. My modeler is on a plane right now so I probably won't have the Nylon version in hand for two weeks. I want to take a heat gun to a printed one (and an original) and soak printed one in water before I start selling them.

Worked with my tail light project.