I confirmed that with the e3 plate, the fan switch must be mounted with the plug facing the roof. There is no way to have it face the floor without interfering with the radio. It makes sense that it fits this way because the e3 has seven grilles on the vent, and the knobs are spaced farther apart than that on the E9. There actually isn't that much interference with my face plate and the radio, I'd say about 4-5mm. I suspect that it is just a design flaw with my latest revisions (not the modeler's fault).

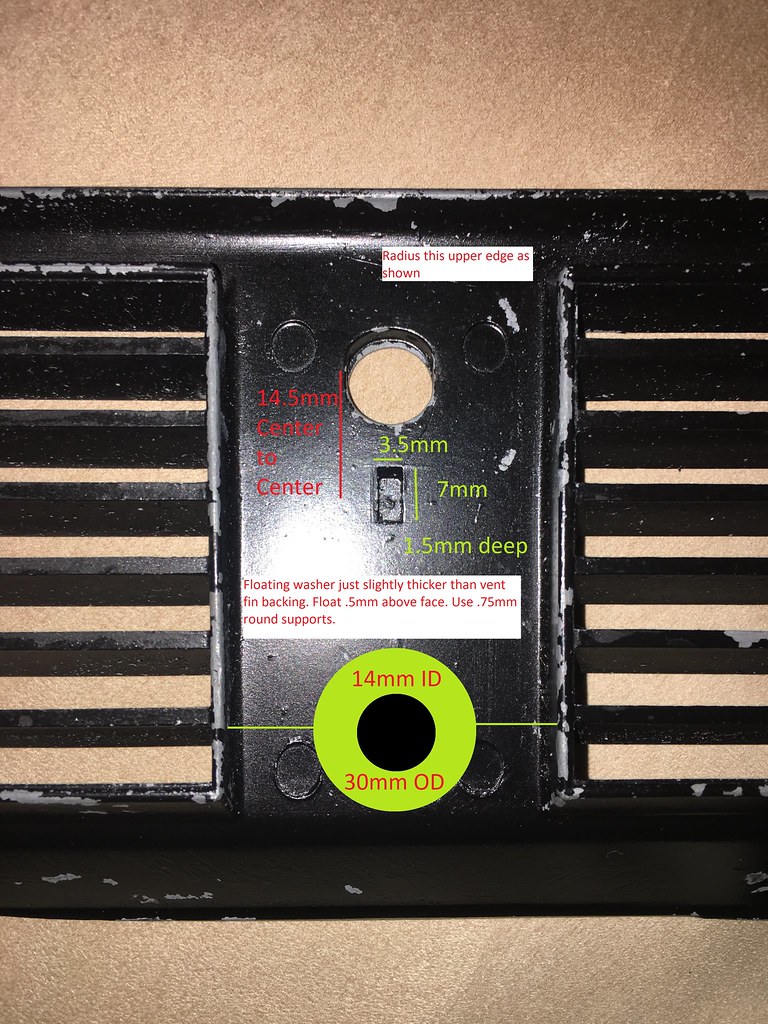

Here is the e3 plate with the switches oriented without interference. @mulberryworks - observe your future pigtail....

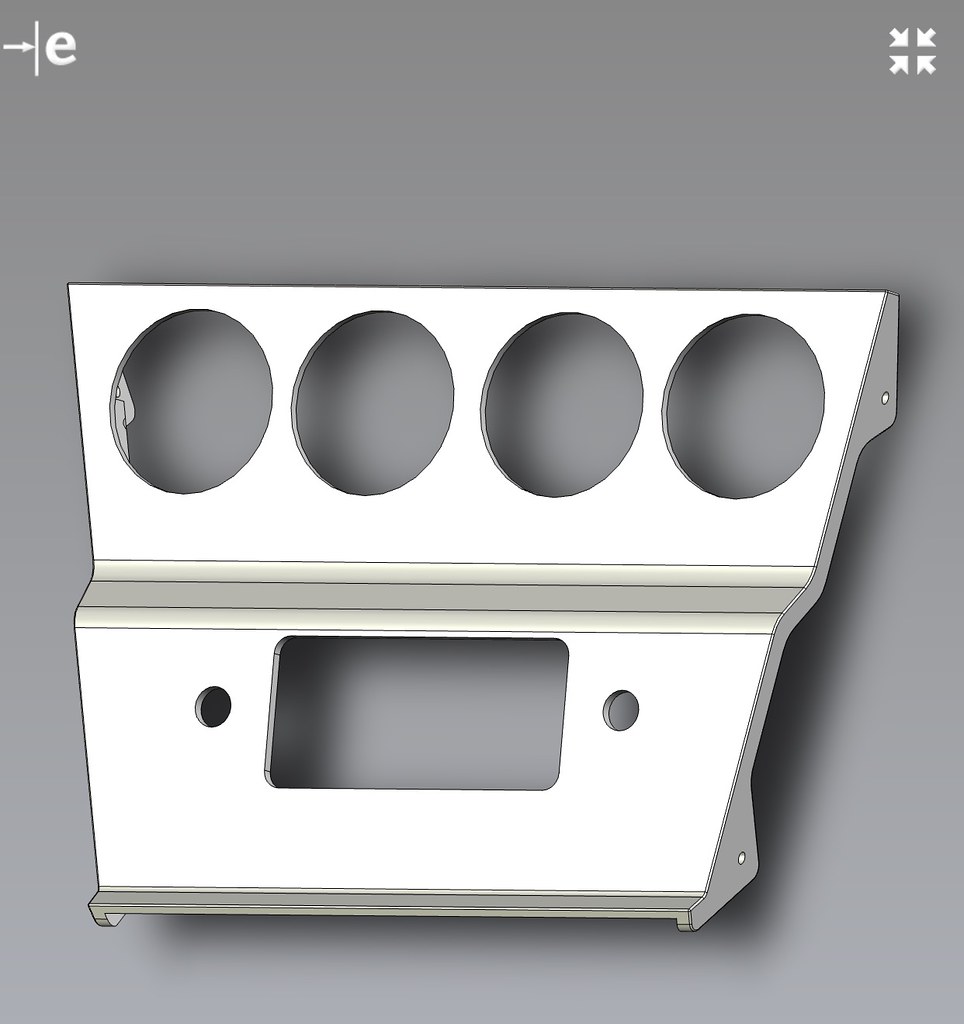

Here is my latest AC face plate print - the problem child:

More R&D this weekend between landscaping projects...

Here is the e3 plate with the switches oriented without interference. @mulberryworks - observe your future pigtail....

Here is my latest AC face plate print - the problem child:

More R&D this weekend between landscaping projects...