Very cool. Looks like it was designed by the Illuminati and Da Vinci’s secrets are inside.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

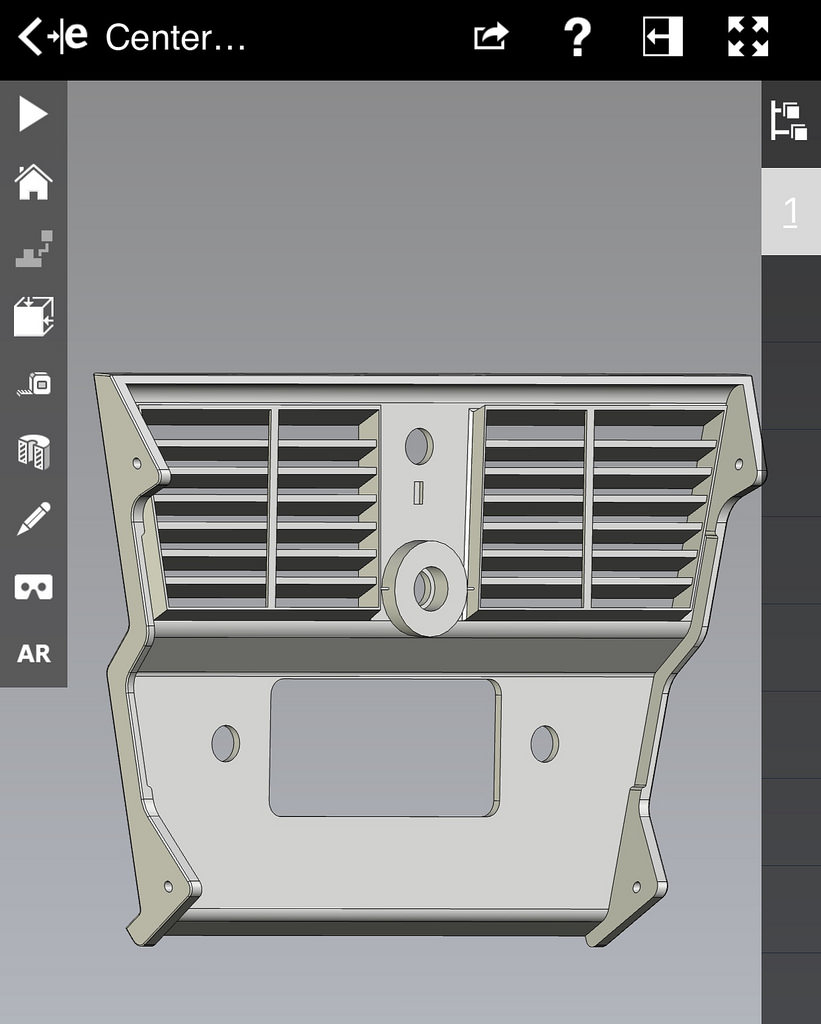

3D Printing: AC Face Plate & Console Vent Covers

- Thread starter Markos

- Start date

You mean all the strange markings? The software lets you manually align views if the auto align as issues

Having identifiable markings helps that process

Having identifiable markings helps that process

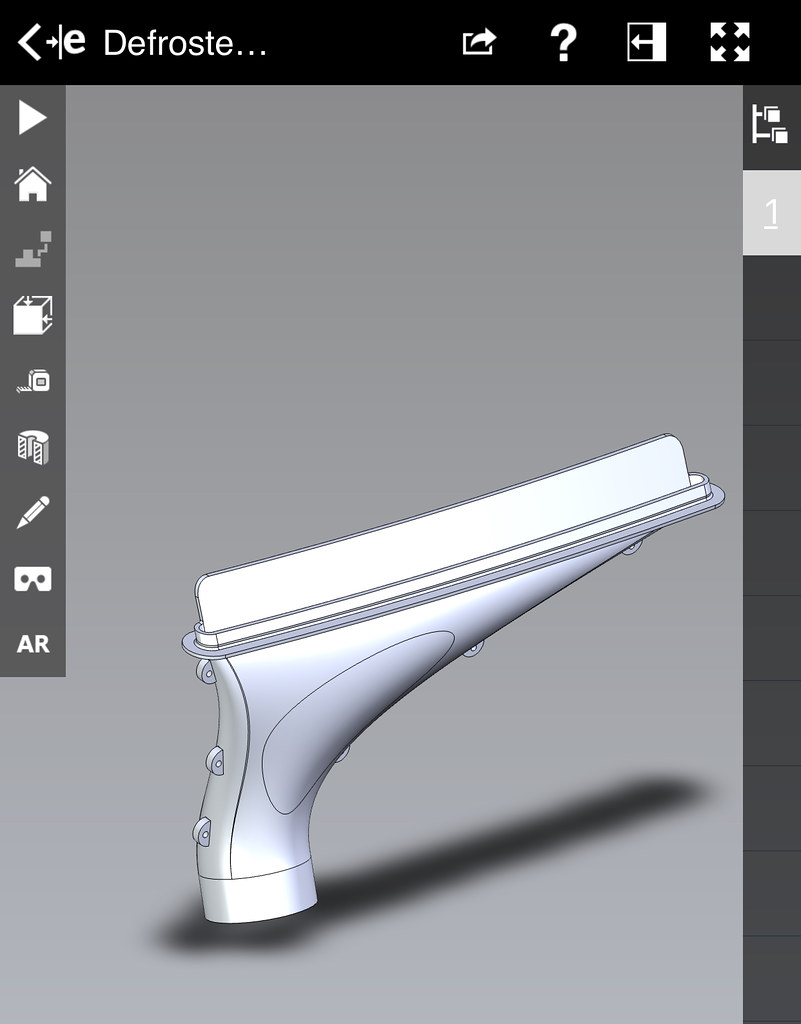

Update: Still waiting on the arrival of a reference AC face plate. My “block model” for the defroster vent looks a lot more like a rough draft. Now it is on me to dig my good vents out of storage and take some measurements. Work is very busy at the moment so hope to keep on top of this!

duplicate.

Slow and steady wins this race. One year in the making!

My modeler now has a pristine original face plate as well as a physical print of his V4 file. I have a conference call setup tomorrow to talk through the corrections.

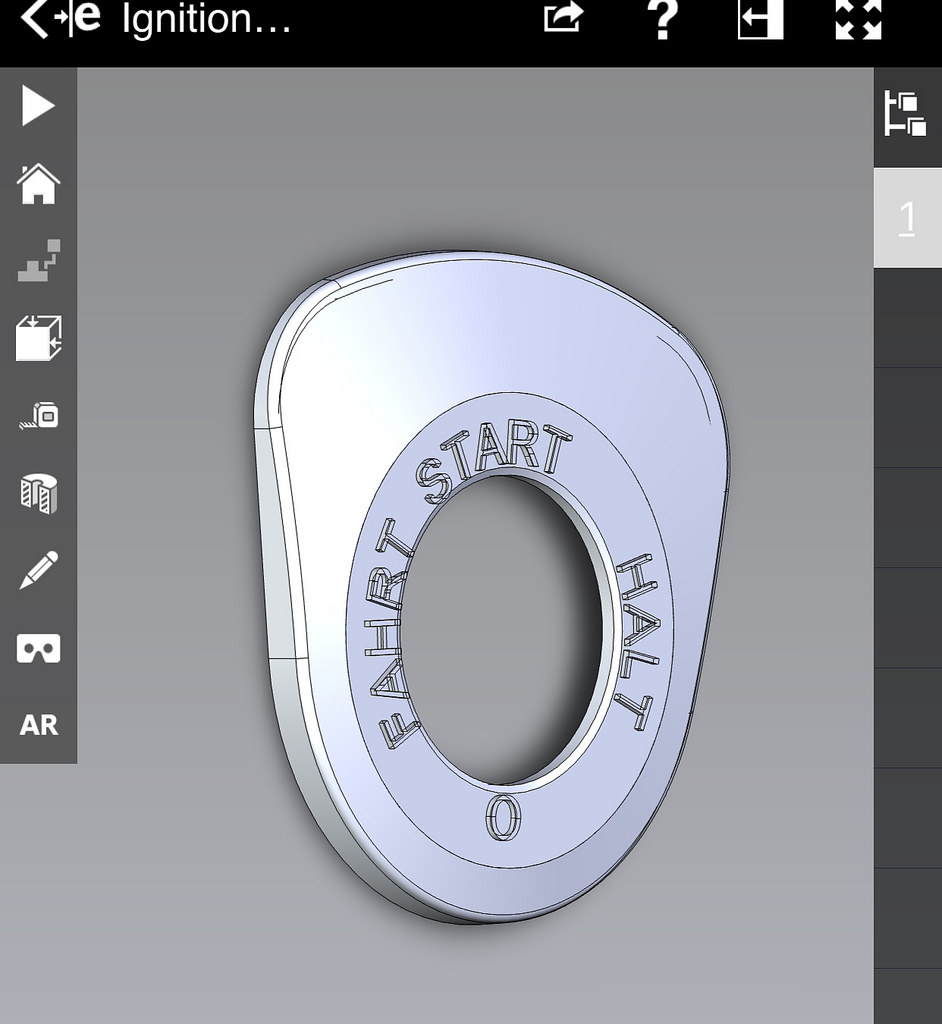

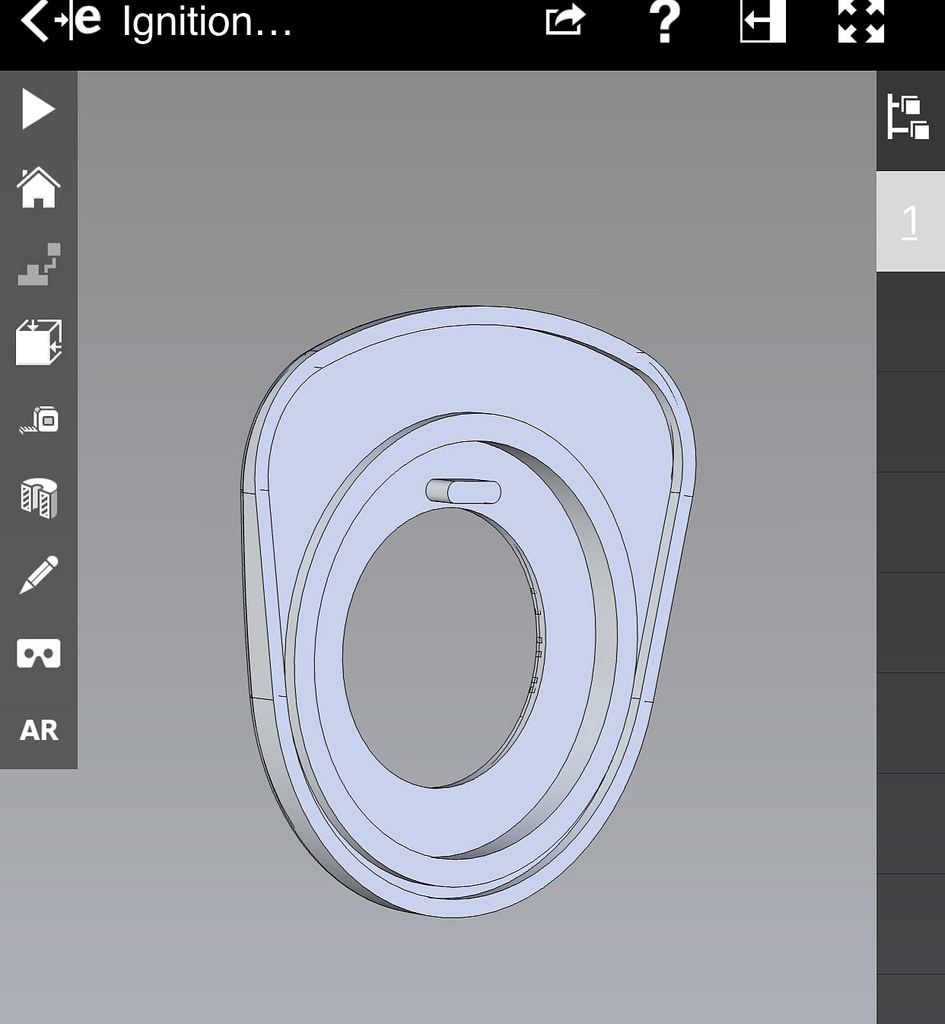

He also received an ignition switch cover with the raised German labels.

I still need to unpack my dashboard to measure the defroster vent.

More very soon!!!

My modeler now has a pristine original face plate as well as a physical print of his V4 file. I have a conference call setup tomorrow to talk through the corrections.

He also received an ignition switch cover with the raised German labels.

I still need to unpack my dashboard to measure the defroster vent.

More very soon!!!

Hey Mark, wondering (maybe you mentioned it in this long thread), but what are the UV characteristics of the plastic being used for all these parts?

Sturdy? SHouldn't warp, should it?

Sturdy? SHouldn't warp, should it?

Hey Mark, wondering (maybe you mentioned it in this long thread), but what are the UV characteristics of the plastic being used for all these parts?

Sturdy? SHouldn't warp, should it?

Good question. For the most part I am using SLS Nylon (PA2200 aka PA12). There aren't a lot of documented specs on the UV resistance. It can yellow over time. It is considered "UV Stable" and is more resistant than FDM printed ABS. I have all of my parts dyed black and they still need to be painted for an end-use finish. I need to do more research on the desired material for the ignition cylinder cover and most importantly, the defroster vents (which will see a lot of direct light). There is a UV resistant ABS option for printing also. As far as heat goes, the Nylon has a melting temp of about 350 degrees F.

http://s3.amazonaws.com/xometry.craft/files/specsheets/datasheet-pa-2200-balance-1-0.pdf

Minor update.

I'm a bit behind with this. I finally reached back out to Mark99 to update the diameter of the parking brake handle. I confirmed that Xometetry has ULTEM, which I will use for the relay bases. I still need to find what I did with my relay base.

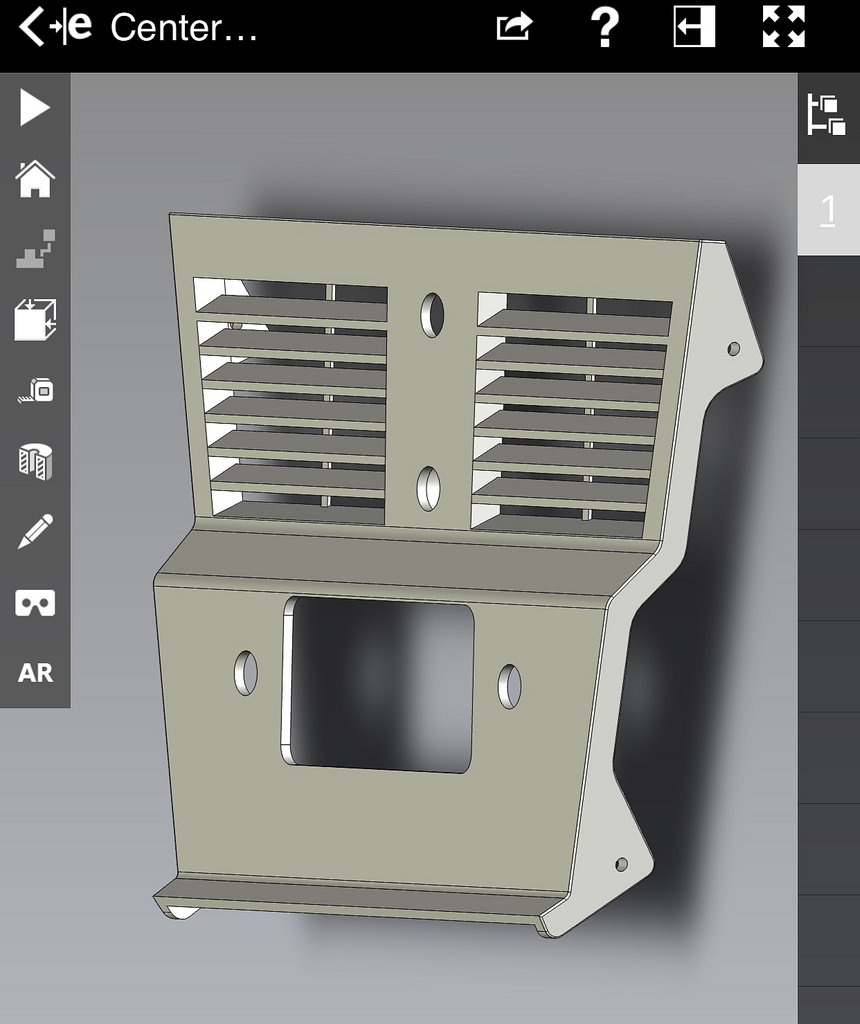

Today I ordered a set of AC side grilles from Xometry. I printed them in Nylon, using Selective Laser Sintering (SLS). It doesn't have stepping like FDM, but it does have a bumpy texture when finished. I opted to have these grilles media tumbled and dyed black. They should arrive next week, and the forum member offered to snap some photos.

Edit: Pic added. Old installed with new on top. He is going to paint with textured rustoleum, same as my radio face plate.

I'm wondering if you can paint the side grilles and while the paint is wet, rub on some elephant skin vinyl on it to give it texture?

https://www.ultrafabrics.com/product_p/3417-23.htm

Attachments

<snip> (double post)

I'm wondering if you can paint the side grilles and while the paint is wet, rub on some elephant skin vinyl on it to give it texture?

https://www.ultrafabrics.com/product_p/3417-23.htm

You could slather the grille with glue, lay the fabric over the part, then vacuum adhere it to the grille. This is how Sven did his wood veneer. He used a food saver. It is on my list of “tools”.

That would be a bit challenging w/the slats?

That would be a bit challenging w/the slats?

Well you would need to use an exacto knife to cut out the slots after the glue dried.

It's printing time!

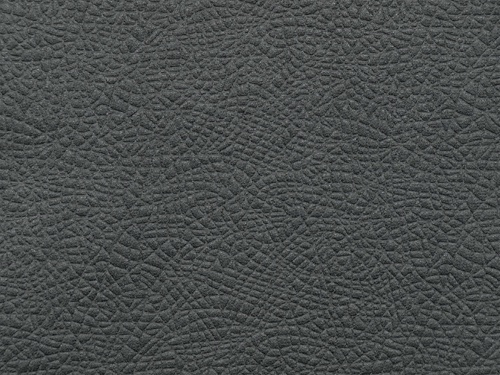

The face plate looks excellent. I'll kick off a print job later today.

I plan to print the ignition cover is UV resistant black ABS. It should be for sale for $20 shipped. That's about double the cost of the e12 version without the lettering. They seem to be out of stock quite a bit as well. This is the perfect candidate for 3D printing. Inexpensive to model, inexpensive to print. I'm going to print this one off and bench test on my spare steering column.

Mark,

In the link below you’ll find all the files for the ignition and the fixed Center Consol. I made quite a few adjustments, some dimensions that we hadn’t noticed as “wrong” were different with the metal one I was sent, so there are changes all over the file. I believe that this is now correct, and we shouldn’t have issues. The washer and indent are included.

The face plate looks excellent. I'll kick off a print job later today.

I plan to print the ignition cover is UV resistant black ABS. It should be for sale for $20 shipped. That's about double the cost of the e12 version without the lettering. They seem to be out of stock quite a bit as well. This is the perfect candidate for 3D printing. Inexpensive to model, inexpensive to print. I'm going to print this one off and bench test on my spare steering column.

Markos,

Put me down for an ignition cover.

Walter

Put me down for an ignition cover.

Walter

These models are looking really good, Mark. This is a promising avenue. How soon 'til we just 3D print the whole car?

Maybe 3d print the stainless strip pieces on the inside door cards and have them plastic-chromed?

Right. Not only does this replicate a hard to find/unavailable part, every metal piece we replace with this process makes the car lighter. That's not a terrible thing in most cases. Kinda why CSL's are so cool...teahead said:Maybe 3d print the stainless strip pieces on the inside door cards and have them plastic-chromed?

Maybe 3d print the stainless strip pieces on the inside door cards and have them plastic-chromed?

It is definitely possible. The bounding box of most 3D printers are typically about 18” or so. It would be tough to find a printer to do it. Also, you would want to print them in plastic or vinyl. Stainless would probably be $500 a strip.

I got a call from the printer. They are concerned about the font coming out on the ignition cover with ASA (UV resistant ABS). They suspect that post processing will cause it to deteriorate. I asked that they print anyway. I’m going to kick off another in Nylon but he suspects that it may still be an issue.

MAKE THEM INDENTED INSTEAD OF PROJECTING