Wladek

Well-Known Member

Finally in June i started main bodywork.

Previous owner in his bodywork didn't treated e9 as it should be.

Someone welded parts like... i don't know how to call that .

.

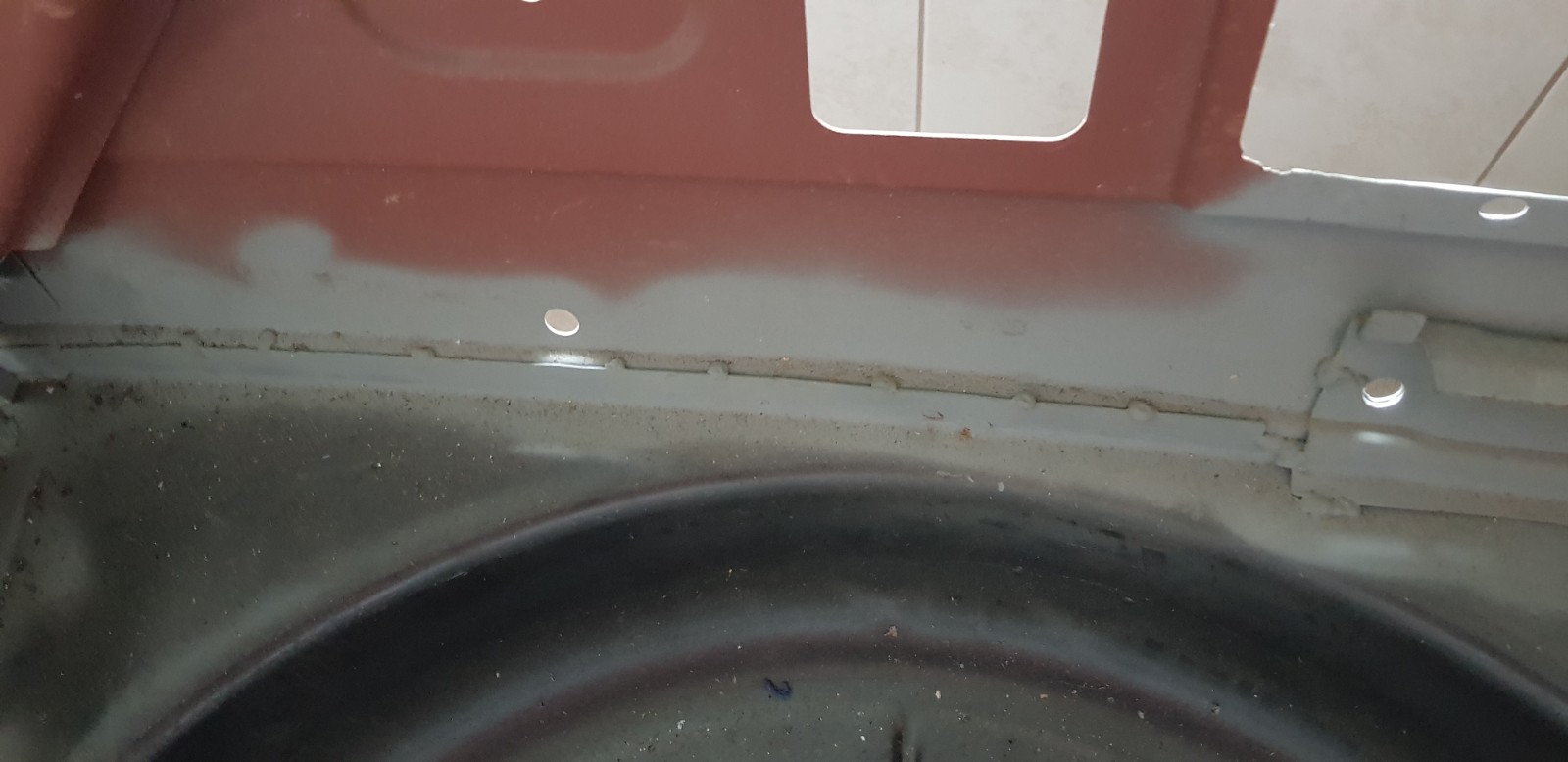

At this photo you can see that wheel arch have proper flat edge.... take at next photo below....

Previous welder/owner because of too short rear right quarter couldn't fit trunk floor on the length, so he deciced to bend the arch & cut new floor panel instead of doing that proper way now i have to remove his ugly welds partially destroying new floor panel

now i have to remove his ugly welds partially destroying new floor panel

Previous owner in his bodywork didn't treated e9 as it should be.

Someone welded parts like... i don't know how to call that

At this photo you can see that wheel arch have proper flat edge.... take at next photo below....

Previous welder/owner because of too short rear right quarter couldn't fit trunk floor on the length, so he deciced to bend the arch & cut new floor panel instead of doing that proper way

Last edited: