Marc-M

Well-Known Member

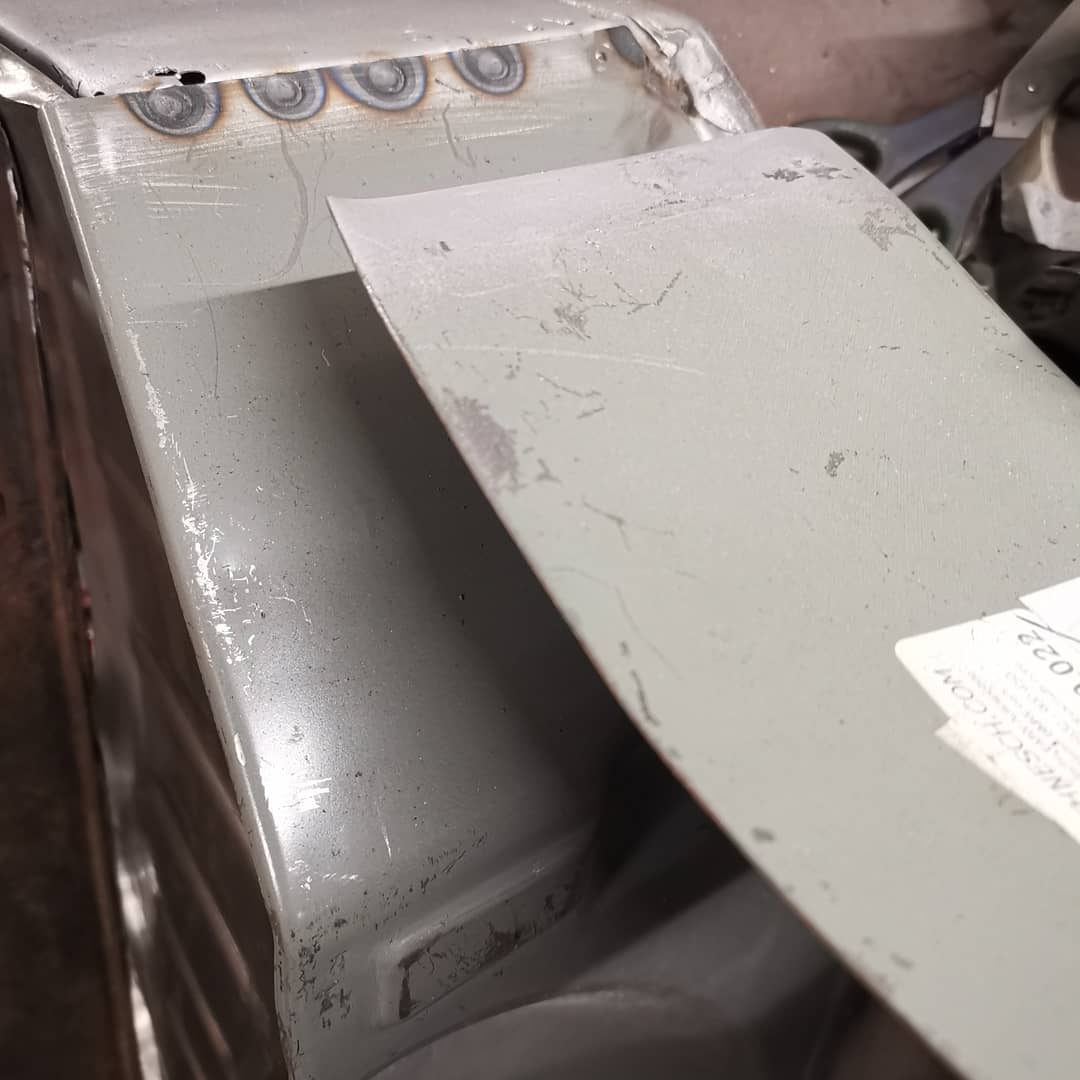

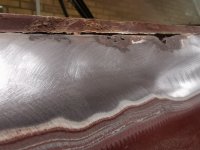

I have all the repair sections for the inner wing - I got them last year from WN - but I then came across new old stock complete inner wings for rhs and lhs , in fact I got the repair sections for both sides - will do a deal with you if you want them...im in Preston Lancashire and send them down next day via TNT..

Regards

Marc

Regards

Marc