Well it’s been while since I have done anything major to the CSL – but now I’m back from holidays I’m ready to get stuck back in.

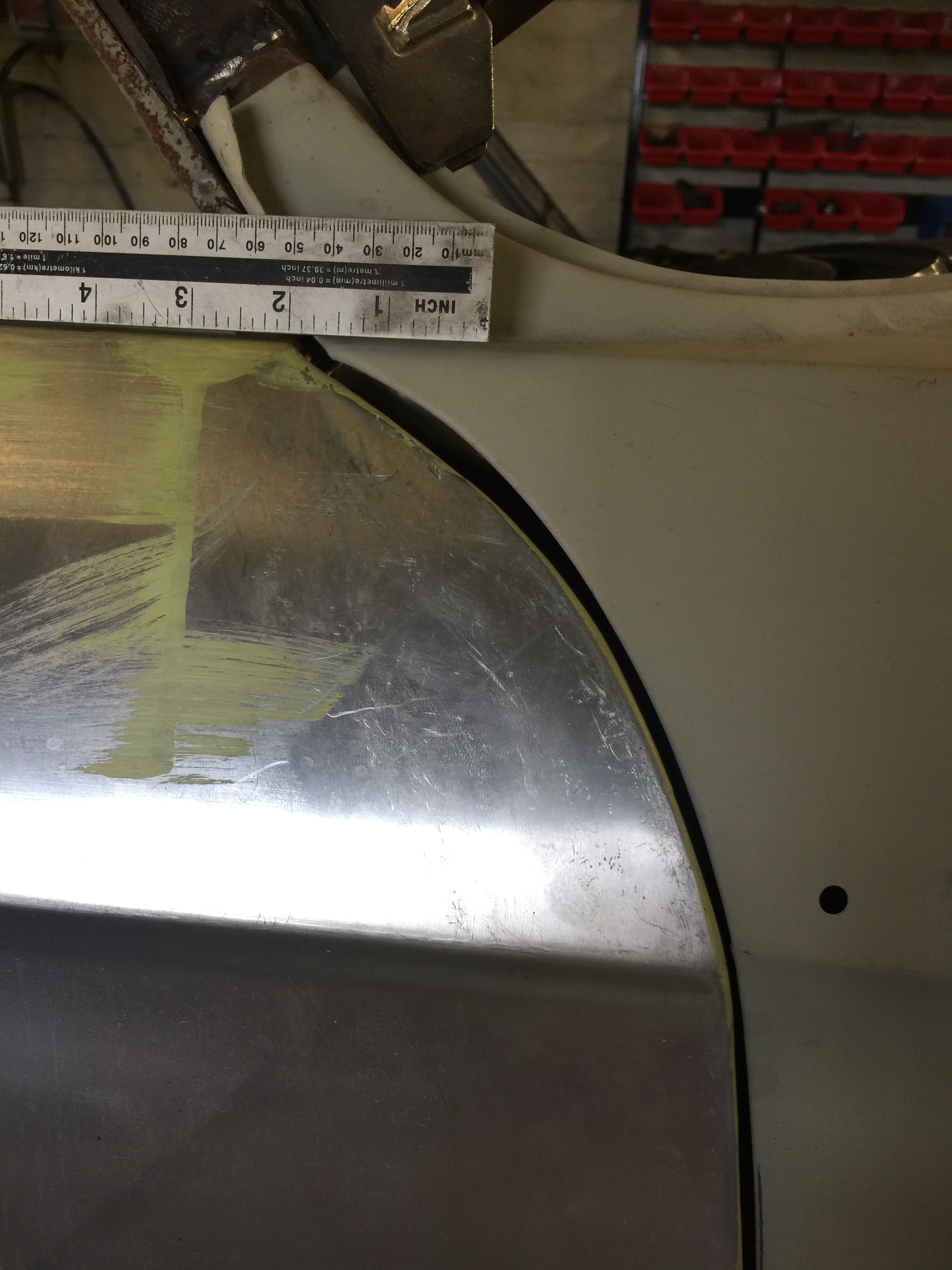

I had temporarily mounted the RHS outer panels Inc. the sills to ensure that my panel gaps were something like, and with a bit of jiggling I got them something like, not perfect, but that will come later.

I have decided not to fix any of the outside panels until all of the inside work is done, and only then shall I fix all the wings, bonnet, trunk and sills in one big outer skinning exercise, I think this will give me better gaps.

I think this way I will get the best results.

I will be trial fitting the panels as I go along, just like I have with the windscreen, just to keep a good check.

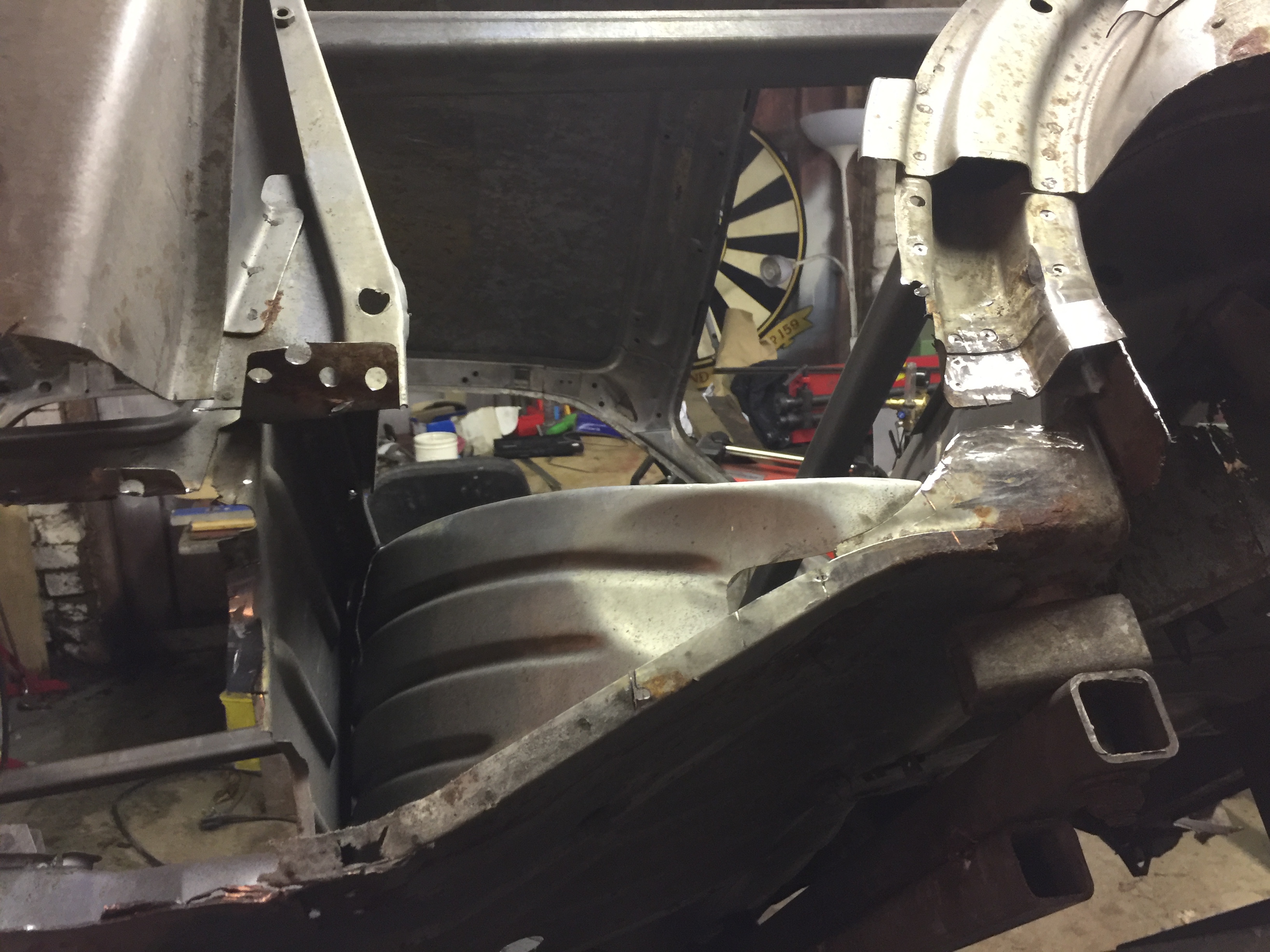

Last night it was time to start on the other side, so took the front inner wing off and the nose section.

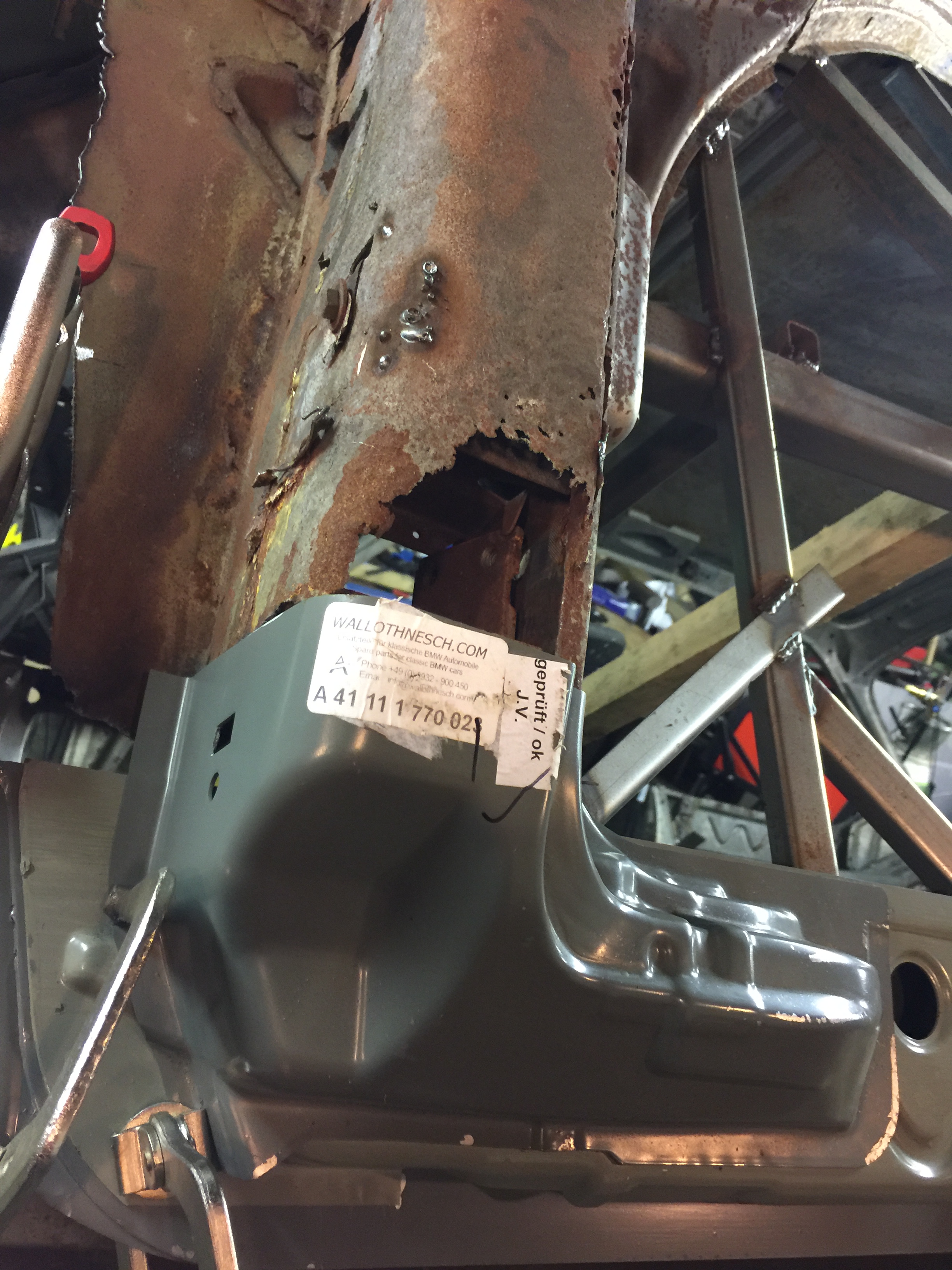

These are in really bad shape; however, I have most of the panes for the front, I’m think I’m going to have to buy a new inner wheel arch – (shite – these are not cheap) as there has been so much botching done on it, as I’m not sure I can get it looking factory looking.

Same story as the other side, Tin worm has worked its way through most of the structure and with a little help from the Plasma cutter, I have started nibbling my way through the Tin.

I need to do some more re enforcements and some extra cross bracing, so today I will get some box section.

Now that's what I call a botch up welding/ brazing job....must be 20 patches on it..

Just a little bit of work to do on the bulkhead! -