Things are going quite smoothly, and progressing quickly (well my quick that is)

The rear wheel arch is 90% done and I must say the Wallis and Gromit repair section was close on prefect fit.

Its contours fitted the existing outer section with a small amount of dolly work and the inner section that fits into the rear wing return was perfect…

As you can see from the pictures (the before and after) I was thinking the section would not cover all the corrosion, but apart from the small section I had to put in at the top, it did – so a result….

Shame that BMW now are running out of full sections and that E9s are now becoming harder to find original body parts for than say a 1930s Bentley or any Jaguar etc…

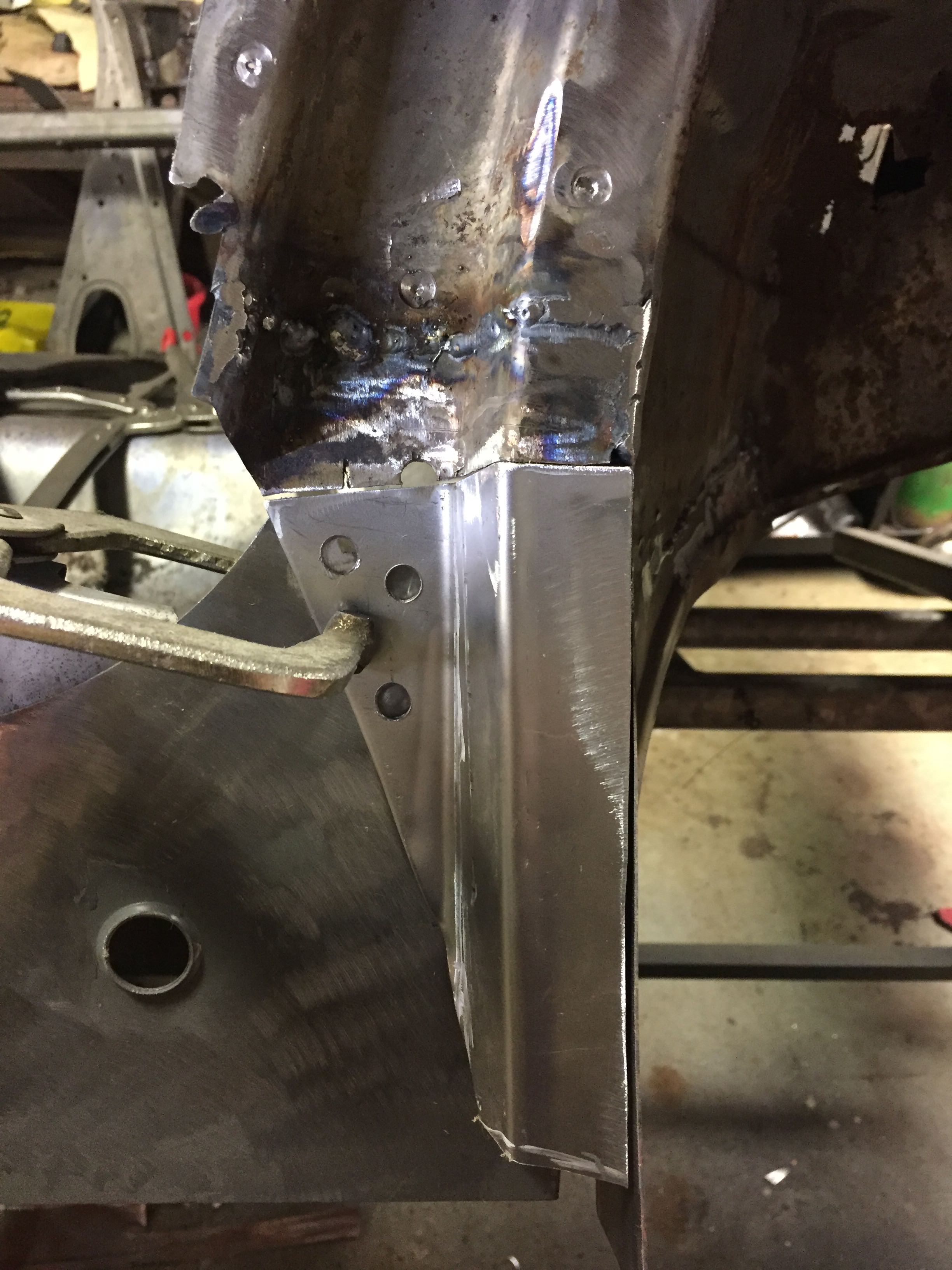

I think it great that there is an industry replicating the repair sections but in my case. a British car that has existed in wet damp, shitty weather has become a so corroded – the sections that the repair section butts up to are getting so thin, that you have to make more sections for them to work.

Then when you weld these in, you blow through the seam with your MiG set on ultra-low setting due to all the car getting thin steel…. I don’t mind, and its therapeutic, but the guy who has a little less experience with welding would find this car a hard one to restore.

In my eagerness to grind off the weld on the wheel arch repair section, I managed to grind off too much in one place and so I will need to make another repair… what a plonker I am…

Still more cleaning up the weld and a bit of dolly work, but the wheel arch is now looking solid.

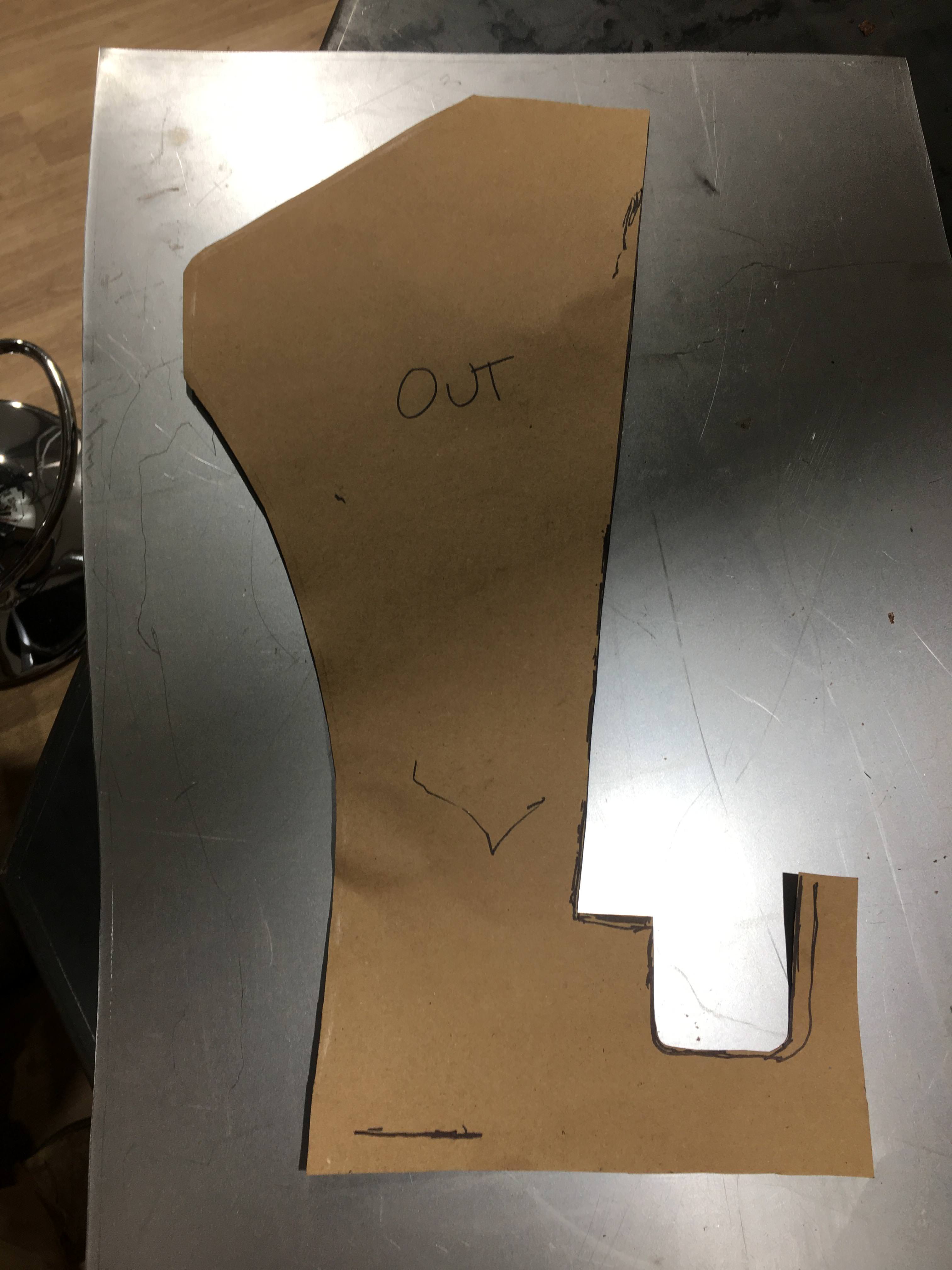

I decided to then replace the floor section… so one night this week was dedicated to take out all the old repairs, carefully trying to take out the shoddy sections, but keeping as much of the good steel as possible.

In my case the old repairs were tacked over the old rusty bits and then overlapped some 6 inches onto good steel. so, I had to grind off each tack, cut the old repair sections out bit by bit to reveal the full extent of the good steel.

The new Wallis and Gromit floor section was rolled and shrunk to get the contour to the front and then fitted to the car…

Aligned up the swage marks with the existing floor and marked the new swage lines positions… put in the new swage lines only to find one was 5 mm off one of them ---- so had to re do it due to my marking it wrong – I put it down to parallax error!

On a plus note I have now installed a mini fridge in the garage so now I can have a nice cold beer.

I try so hard to only have one beer a night as its all too easy to drink many more and it being a school night as well!

I think this new addition could turn into an addiction, I’m getting the taste of Moretti beer….