Marc-M

Well-Known Member

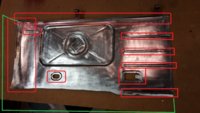

When the car was dipped the A post on the RHS was so bad I had to cut it out completely.

I braced the car up as best I could to stop it moving when chopping out such a large bit of structure.

It is now time to put the section back in, not an easy task to get spot on….

I started by getting my laser measure out and taking precise measurements from the LHS A post to the LHS B Post…

Put in the new A post and adjusted it to the same sizes as the other side…

But then I started worrying about the angles of the A post and had no way to check that they were right, as a spirt level is to vague.

So, a quick look at eBay and I found a cheap “Digital Box Gauge Angle Protractor Level Inclinometer with a Magnetic base”

Set to, taking angle measurements (after getting the car level) from the untouched side and then adjusting the new side to the same angles.

After a good few hours of small adjustments, checking, more checking I managed to get the New A post in the position…. But could not get every location totally spot on….

Every time you moved one spot all the other measurements and angles change… its out by 2mm out at the worst spot and within 0.5mm in its best spot – the angles are 0.5 degrees at its worst, but perfect at the best spots.

Welded it in – only when I put the wings and door on will I know its correct….

I don't fancy taking it out now its all welded in!

I braced the car up as best I could to stop it moving when chopping out such a large bit of structure.

It is now time to put the section back in, not an easy task to get spot on….

I started by getting my laser measure out and taking precise measurements from the LHS A post to the LHS B Post…

Put in the new A post and adjusted it to the same sizes as the other side…

But then I started worrying about the angles of the A post and had no way to check that they were right, as a spirt level is to vague.

So, a quick look at eBay and I found a cheap “Digital Box Gauge Angle Protractor Level Inclinometer with a Magnetic base”

Set to, taking angle measurements (after getting the car level) from the untouched side and then adjusting the new side to the same angles.

After a good few hours of small adjustments, checking, more checking I managed to get the New A post in the position…. But could not get every location totally spot on….

Every time you moved one spot all the other measurements and angles change… its out by 2mm out at the worst spot and within 0.5mm in its best spot – the angles are 0.5 degrees at its worst, but perfect at the best spots.

Welded it in – only when I put the wings and door on will I know its correct….

I don't fancy taking it out now its all welded in!