Setup for working at the underside

Just for documentation purposes; someone may find this usefull.

my dilemma was the following:

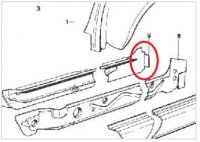

- I want to clean the underside from old undercoating and some rust spots & and have good acces to my sills.

- I have only a small lift available, going up about 90 centimeters; 3 foot or so. This lift however has a centre frame that covers the whole center axis of the car; from drain plug to drainplug. It leaves no acces to exhaust, drive shaft bearings, large parts of the floor sections etc.

- My engine is still in as i don't have the space to park it....

Now to replace the sills, I reinforced the body with an internal frame as the standard practise to keep the rigidity; It turned into half a roll cage.

Now the ensure this was done right and level, I constructed 4 steel 'blocks' that support the wheels, they are just over 60cm (2 foot) high. I levelled the 'blocks' with a laser so that each wheel is on a level surface.

Turned out my garage floor is more then 3 cm off from horizontal.

Hopefully all the effort will pay off in doors that will show a good fit without endless 'adjustments' later on.

The pictures had to be made in the dark, because it just a crappy 30 euro laser and the red line doesn't show on a photo unless the lights were switched off.....

Erik

Just for documentation purposes; someone may find this usefull.

my dilemma was the following:

- I want to clean the underside from old undercoating and some rust spots & and have good acces to my sills.

- I have only a small lift available, going up about 90 centimeters; 3 foot or so. This lift however has a centre frame that covers the whole center axis of the car; from drain plug to drainplug. It leaves no acces to exhaust, drive shaft bearings, large parts of the floor sections etc.

- My engine is still in as i don't have the space to park it....

Now to replace the sills, I reinforced the body with an internal frame as the standard practise to keep the rigidity; It turned into half a roll cage.

Now the ensure this was done right and level, I constructed 4 steel 'blocks' that support the wheels, they are just over 60cm (2 foot) high. I levelled the 'blocks' with a laser so that each wheel is on a level surface.

Turned out my garage floor is more then 3 cm off from horizontal.

Hopefully all the effort will pay off in doors that will show a good fit without endless 'adjustments' later on.

The pictures had to be made in the dark, because it just a crappy 30 euro laser and the red line doesn't show on a photo unless the lights were switched off.....

Erik