part getting welded back in after 4 years....

Sometimes things are rewarding...

I learn along the way; its easy to cut out stuff, but its a 100 times more difficult to put them back in and be satisfied with the endresult.

today was one day to be satisfied, parts are being put back in the car where they belong. En route to ressurection!

the first pic shows the steel internal frame (jig) that I use to locate the subframe mount exaclty in 3D back in the location where it came from

2nd pic shows the preparation, clean the weld area's.

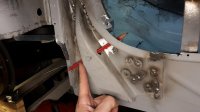

3rd pic shows the part trial fitted with Cleco's. exact alignment during welding was done with the steel frame (jig)

4rth pic shows the welding, wherre I tried to reproduce weld type, size and location from original situation.

Pic 5 shows the view from inside the rear wheelarch, looking towards the front. here you see one modification that was made by me. Normally the inner Sill ends at the red line. I had to replace that section of the inner sill anyway (2,5 mm steelthickness), and decided to stretch it further around the corner. This allows me to weld the subframe mount to it, instead of welding it only to the 0,8mm thick wheel well sheet as in the original design.

last pic, 6, shows the endresult, welds cleaned where needed, epoxy painted and all.