Taking a step back from my project, (which is hard if you can stand no further then 2 feet away from the car in my garage), I'm happy to see the rightside front and rear right floors are finished, and the sill is closed up again. All that's left to do is to weld the outer skins and fit the rocker covers. However I'm going to do that as a very last task, honing my welding skills until I feel confident enough, but I also want to do this having the doors in place to check the panel alignment. And as I welded half a roll cage temporarily in my car, the doors won't close until I cut the frame out again.

Which means I must fix the floors, sill, A & B-pillars and subframe mount on the left side before I'm able to remove the inner frame.

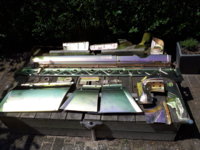

So I removed the rear axle (again) and chopped some metal and ended up with this:

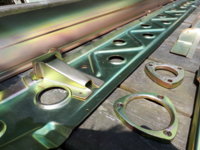

The rear floor has some punctures and rust holes near the sill, looks like it went wrong trying to lift the car at some point in it's life. The rectangular area around the drain plug is still quite good. (available for free should anyone want to replace just the drain plug area).

I'm replacing it entirely as I also want to fix all the rust that creeps up in the floor to sill joint.

I carefully measured and drawn the shape of the W&N replacement part on the floor (solid black line) and drawn cut marks (dashed line) inside it. I took care not grinding into the frame rails. I want to keep them intact to use as a height reference when installing the new floor. The inside of the frame rails is actually really solid. Most of the brown stuff you see in the pic is old wax; some rust on the underside of the floor so it's good to replace it entirely.

Which means I must fix the floors, sill, A & B-pillars and subframe mount on the left side before I'm able to remove the inner frame.

So I removed the rear axle (again) and chopped some metal and ended up with this:

The rear floor has some punctures and rust holes near the sill, looks like it went wrong trying to lift the car at some point in it's life. The rectangular area around the drain plug is still quite good. (available for free should anyone want to replace just the drain plug area).

I'm replacing it entirely as I also want to fix all the rust that creeps up in the floor to sill joint.

I carefully measured and drawn the shape of the W&N replacement part on the floor (solid black line) and drawn cut marks (dashed line) inside it. I took care not grinding into the frame rails. I want to keep them intact to use as a height reference when installing the new floor. The inside of the frame rails is actually really solid. Most of the brown stuff you see in the pic is old wax; some rust on the underside of the floor so it's good to replace it entirely.

Attachments

-

20180120_120216 traced solid outline of w&N panel and dashed cut mark.jpg211 KB · Views: 678

20180120_120216 traced solid outline of w&N panel and dashed cut mark.jpg211 KB · Views: 678 -

20180120_123445 rear right floor cut out.jpg204.7 KB · Views: 678

20180120_123445 rear right floor cut out.jpg204.7 KB · Views: 678 -

20180120_123513 floor to sill joint rusting and floor holes showing.jpg189 KB · Views: 710

20180120_123513 floor to sill joint rusting and floor holes showing.jpg189 KB · Views: 710 -

20180120_124552 first look into frame rails - keeping it as height reference.jpg204.2 KB · Views: 728

20180120_124552 first look into frame rails - keeping it as height reference.jpg204.2 KB · Views: 728

Last edited: