onwards & a question

Thanks for the support!

Your comments really keep me motivated to keep spending the hours to get everything 100%.

So, in this pursuit, i asked in post #55 about the original definition of the front corners of the floor. there are some flaps under the floor protecting fuel lines etc. and there is also a square with folded edges. Thanks to Afeustel, I know they have to be there. I am considering to glue them on once i have them, as i think this is less chance for moisture getting trapped between the sheets.

Now W&N offer a part, and I wonder if that is the part that I described in post #55.

http://www.wallothnesch.com/karosse...tore=eng&dir=asc&order=name&___from_store=eng

For the life of me, i can't figure out where else the W&N part would be located. But as the shape of the W&N part does not match the shape exactly in the pics of Vranedom's, nor does it show to be on the green car in the BMW museum (although the pic is too vague to be sure).

Questions:

-Can someone confirm if the W&N part (pic 1) is the thing as the red squared part in the pic 2 below?

-what would be the purpose of this part? is it to locate a jack? If so, it is in a horribly weak location.

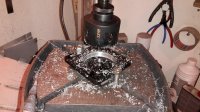

Pic 3&4 are current status of my build. I'm in the process to shape all the passenger side sill parts and making sure they fit 100% before continueing to weld. I want to be able to trial-build all the layers up to the last panel, to check that all is aligned & perfect before welding in the repair patches to the inner sill part and the inner wheelarch.

Note that in pic 4 there are some parts still missing, most importantly the outer skin

wink

, but also a reinforcement that is running down from the outer wheel well onto the yellow intermediate sill.

). So please keep it up ... am looking forward to your next installment!

). So please keep it up ... am looking forward to your next installment!