You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Heartbreak-broken rear shock mount

- Thread starter Stevehose

- Start date

What is the purpose of the inner step at 78mm, why does it not align to the inner diameter at 88mm? Thanks.

@halboyles & @Stevehose ,

I have a spare strut tower top for testing this very purpose. It is currently in the hands of @mark99. You should see if he can send it your way for fitment that is easier on your back.

Fits in a little box. It’s just the part that poked out of the wheel well.

I have a spare strut tower top for testing this very purpose. It is currently in the hands of @mark99. You should see if he can send it your way for fitment that is easier on your back.

Fits in a little box. It’s just the part that poked out of the wheel well.

That is a great idea! I'll contact Mark and see if we can borrow it. I have already printed a test model so this would be a good start for a test fit.I have a spare strut tower top for testing this very purpose.

Last edited:

I think that @mark99 and I were thinking an insert that went inside the cap would be sufficient. Invisible to the naked eye. He mentioned the metal adhesives that they use on car bodies now. You could also drill holes in the side of the house oem tower and plug weld the interior cap.

I’ll leave it to you, but food for thought.

Sent Mark and email with a link to this thread also. If you do get it, feel free to give it an acid bath. If the inside is clean you can use a cheap silicone mold kit to get a cast of the inside. Would recommend before cleaning.

I’ll leave it to you, but food for thought.

Sent Mark and email with a link to this thread also. If you do get it, feel free to give it an acid bath. If the inside is clean you can use a cheap silicone mold kit to get a cast of the inside. Would recommend before cleaning.

That is certainly a fair question. In my case, I simply picked up that part of the design from @Stevehose on post 112. So we should ask him. Absent other answers, I am guessing it was simply to leave a little bit more material around that top corner. But I would certainly ask my machinist if he can smooth it out to match the outer curve.What is the purpose of the inner step at 78mm, why does it not align to the inner diameter at 88mm? Thanks.

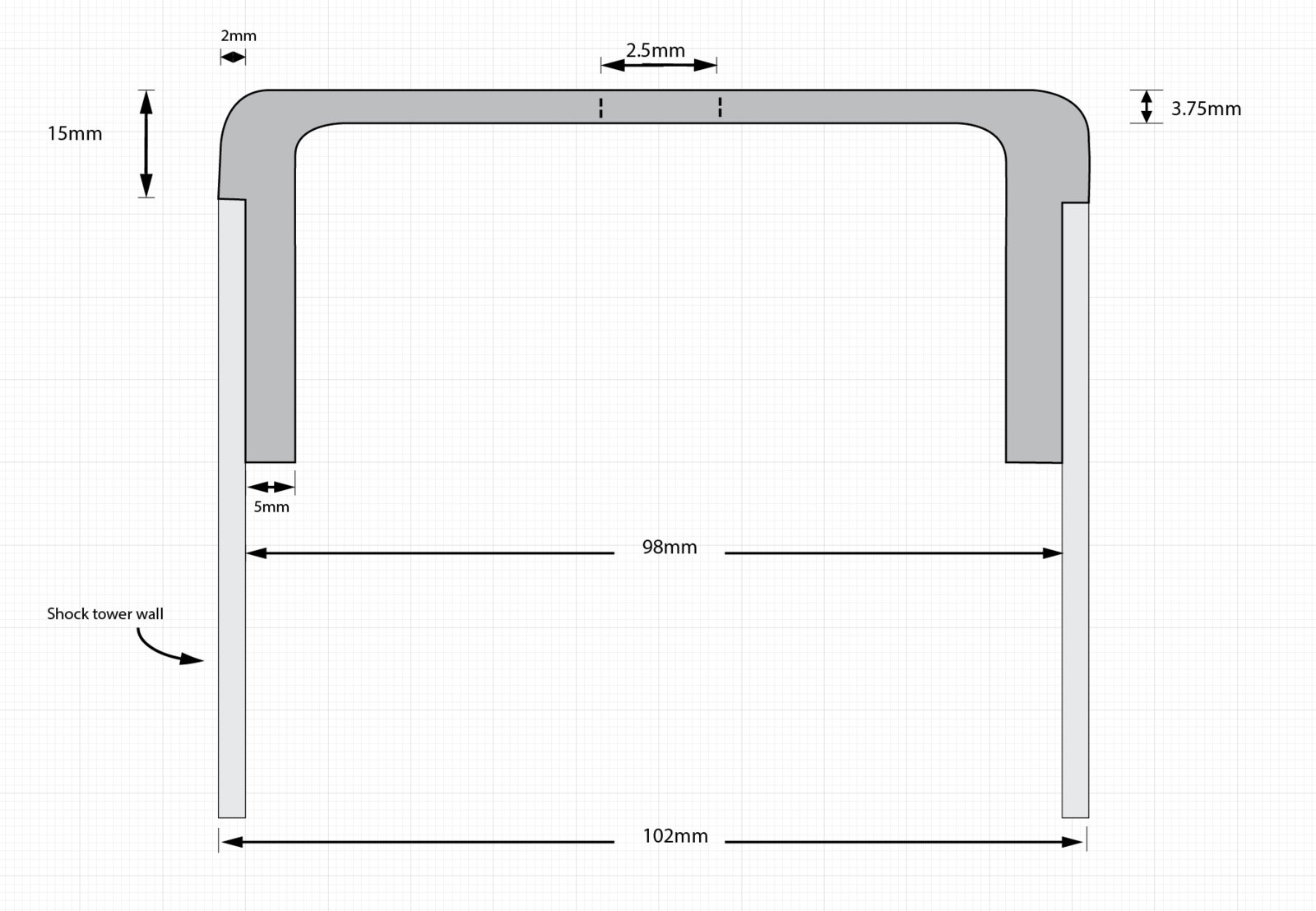

Thanks @autokunst for the nudging and suggestion. Here is an updated drawing without that "78mm step".

I think the inner step was recommended by the machinist for extra strength, sorry but I don't remember exactly.That is certainly a fair question. In my case, I simply picked up that part of the design from @Stevehose on post 112. So we should ask him. Absent other answers, I am guessing it was simply to leave a little bit more material around that top corner. But I would certainly ask my machinist if he can smooth it out to match the outer curve.

Thanks Steve!

How will you cut precisely 15mm from the top, evenly all the way around?

I've got a recently retired mechanical engineer friend in Seattle who's car savvy and has an Italian Graziano lathe. I'll hit him up and see if he's interested in making some of these. Should be an easy thing for him.Thanks @autokunst for the nudging and suggestion. Here is an updated drawing without that "78mm step".

View attachment 133448

Here's a question. How many cars still need to have their shock mounts upgraded in this fashion? And how many owners realize it? There seems to be a good demand for tall light lenses and sun visor pivot mounts but those are where you can see them and it's obvious when they need replacement.

I'm trying to gauge the possible demand for such a part since that will play a big part in the feasibility of getting them produced. Of the 2800 cars in our CSregistry, how many are in need? Any guesses?

I'm trying to gauge the possible demand for such a part since that will play a big part in the feasibility of getting them produced. Of the 2800 cars in our CSregistry, how many are in need? Any guesses?

I would buy them for my project coupe.

LatheHow will you cut precisely 15mm from the top, evenly all the way around?

I am interested in a pair!

Cutting the top off of the support tower would require rather close measurement and slicing. The beauty of having that extra lip is that, even if the cut isn't uniformly 15mm from the top of the original, you could slide the reinforcement into the remaining tower and make adjustments to the cut to seat it where it needs to be before the final welding.How will you cut precisely 15mm from the top, evenly all the way around?

In the trunk?!Lathe

Yea, I get there is a small amount of fudge factor but it still has to be very even... Which led me to my question, of how exactly... Seems simple on the surface but to get it spot on may be a challenge.Cutting the top off of the support tower would require rather close measurement and slicing. The beauty of having that extra lip is that, even if the cut isn't uniformly 15mm from the top of the original, you could slide the reinforcement into the remaining tower and make adjustments to the cut to seat it where it needs to be before the final welding.

So do folks envision welding up inside the shock "tunnel" from under the car where the inside lip is (where the 5mm label is in Bmachine's drawing) or just welding around the perimeter that can be seen from the trunk? Or both?

a 16"x 9" rim (which is what I have on my car) is actually 10" wide as a rim is measured across each lip and the outside of each lip makes up 1/2" either side so that equals 10". My question to others is........regarding the internally fitted reinforcement cap ....to weld the unit in is going to be difficult to access (barely 4" to get welding head inside tower).....also the top of the tower is cut off which in itself makes the tower weaker. Furthermore....why mess around custom building stuff when you can buy something off the shelf. By the look of it, if you have a rear brace that would still fit below an externally fitted reinforcing cap.More importantly, how did you get 10" wheels under your coupe? ! Any pictures?