Some bits to improve,…

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LAN e9 empresas y tribulaciones, an epiphany in 042BBlau. OPUS MAGNA. XXXXXXXXXXXXXXXXXXXXXXXXXX

- Thread starter deQuincey

- Start date

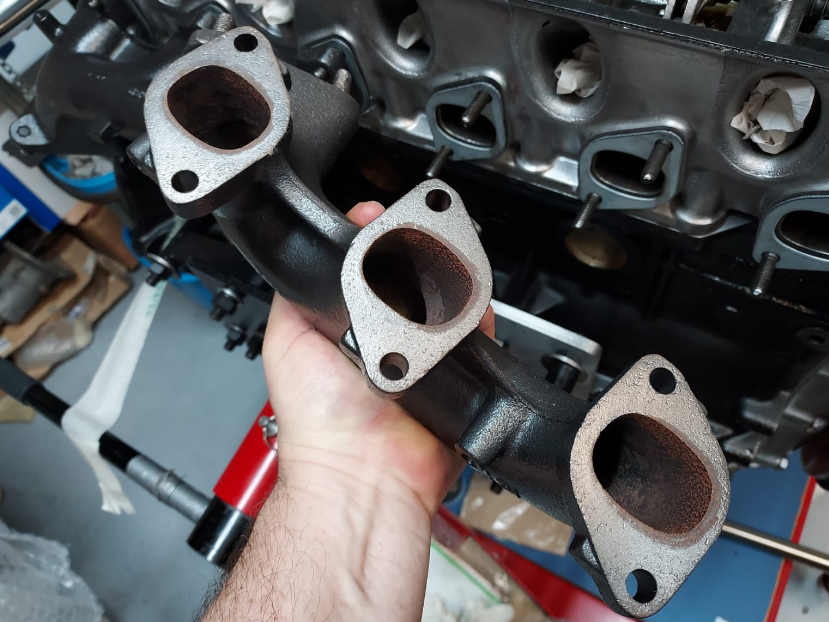

more engine

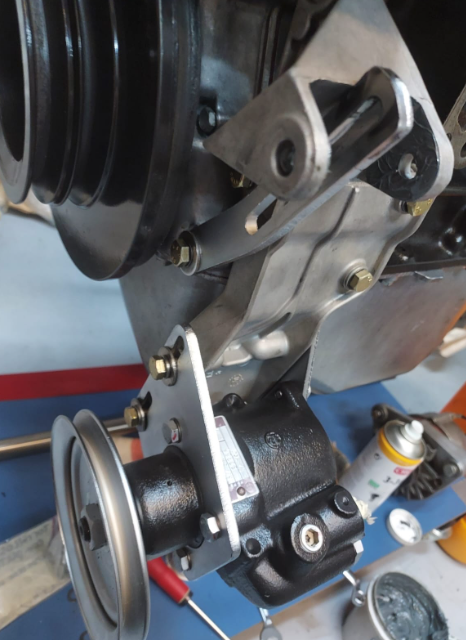

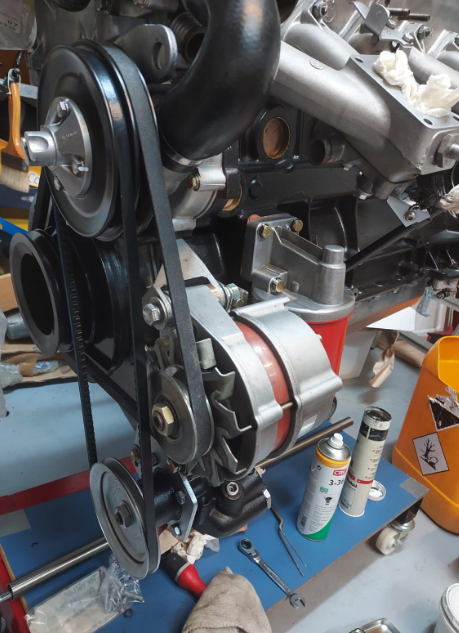

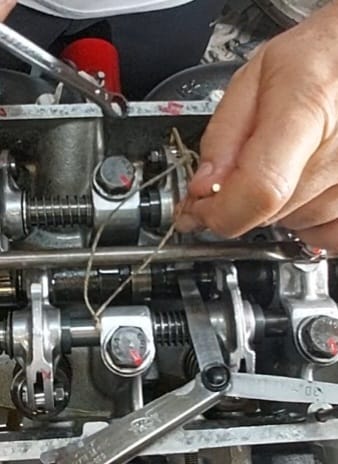

incidentally, here you can see the tensioner , the usual bleeding pouring some oil through window

incidentally, here you can see the tensioner , the usual bleeding pouring some oil through window

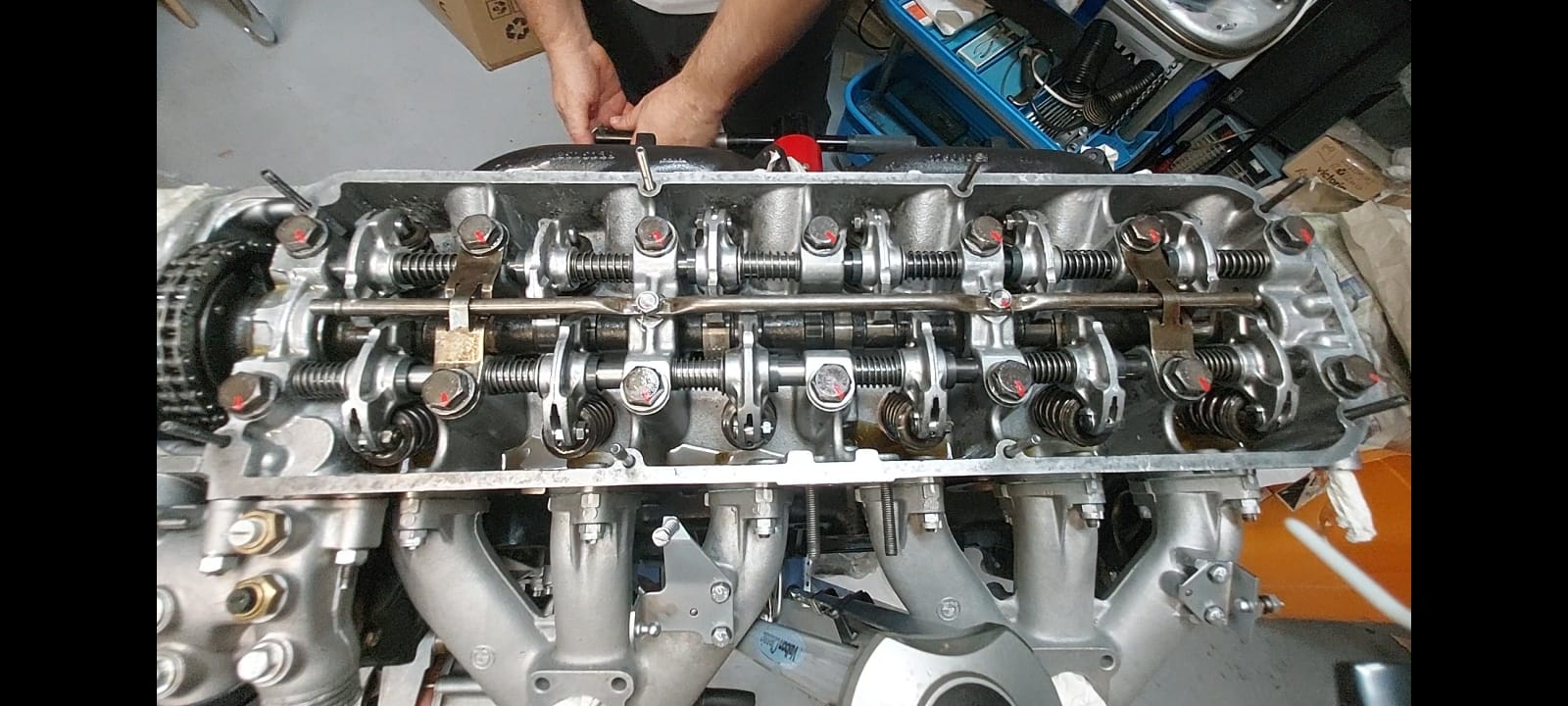

valve gap adjustment

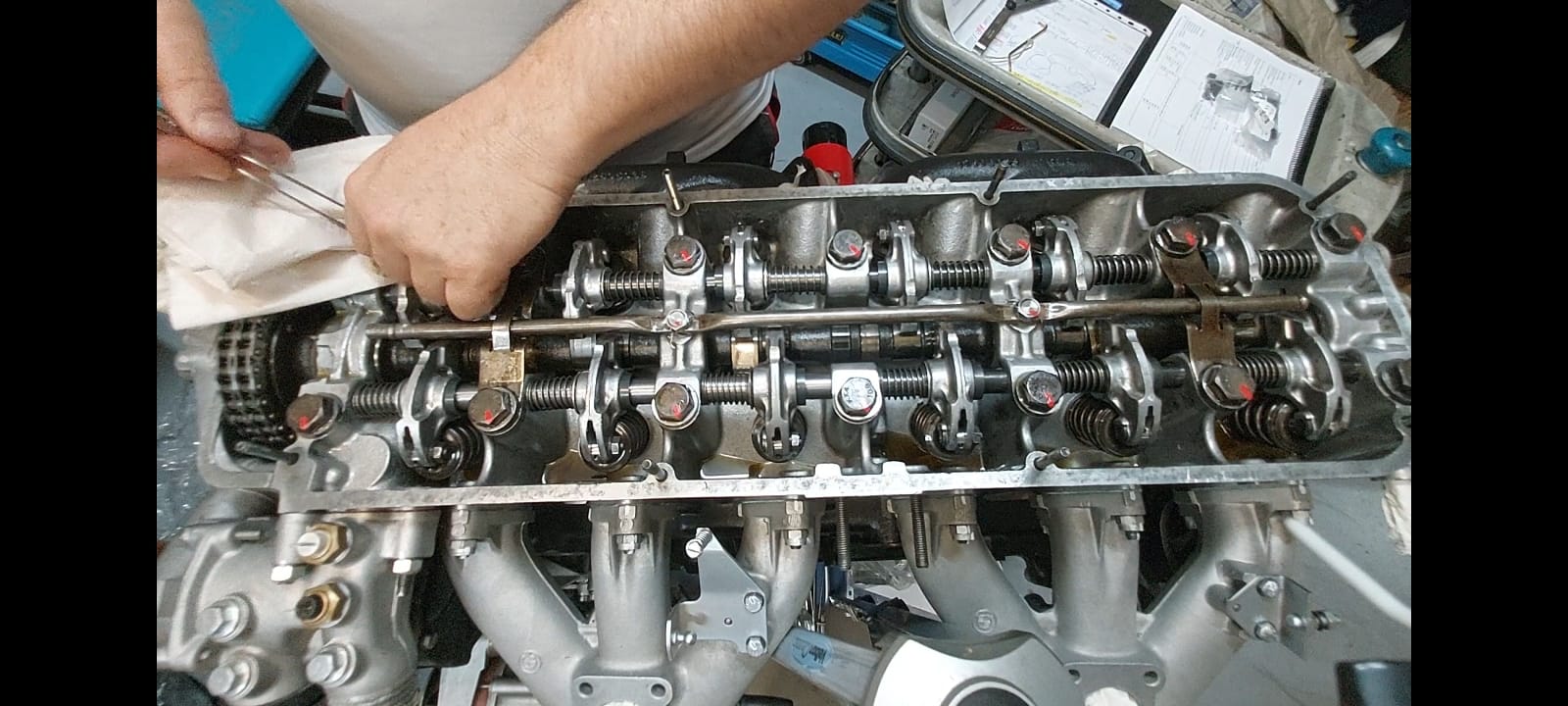

As engine is easy to access now I performed a valve gap adjustment

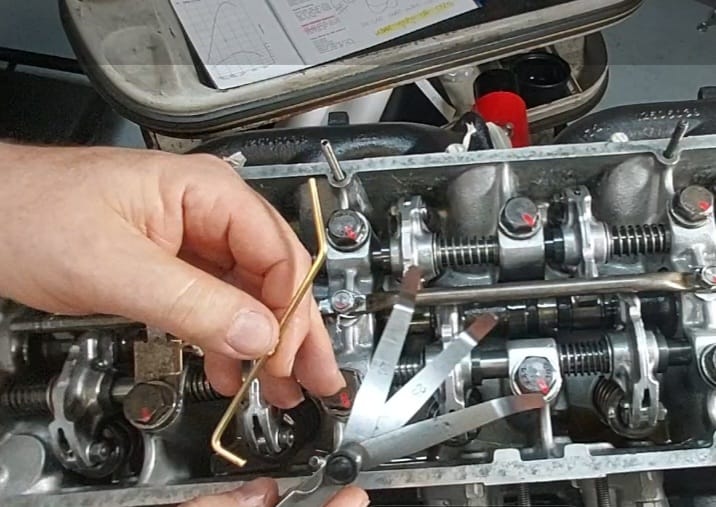

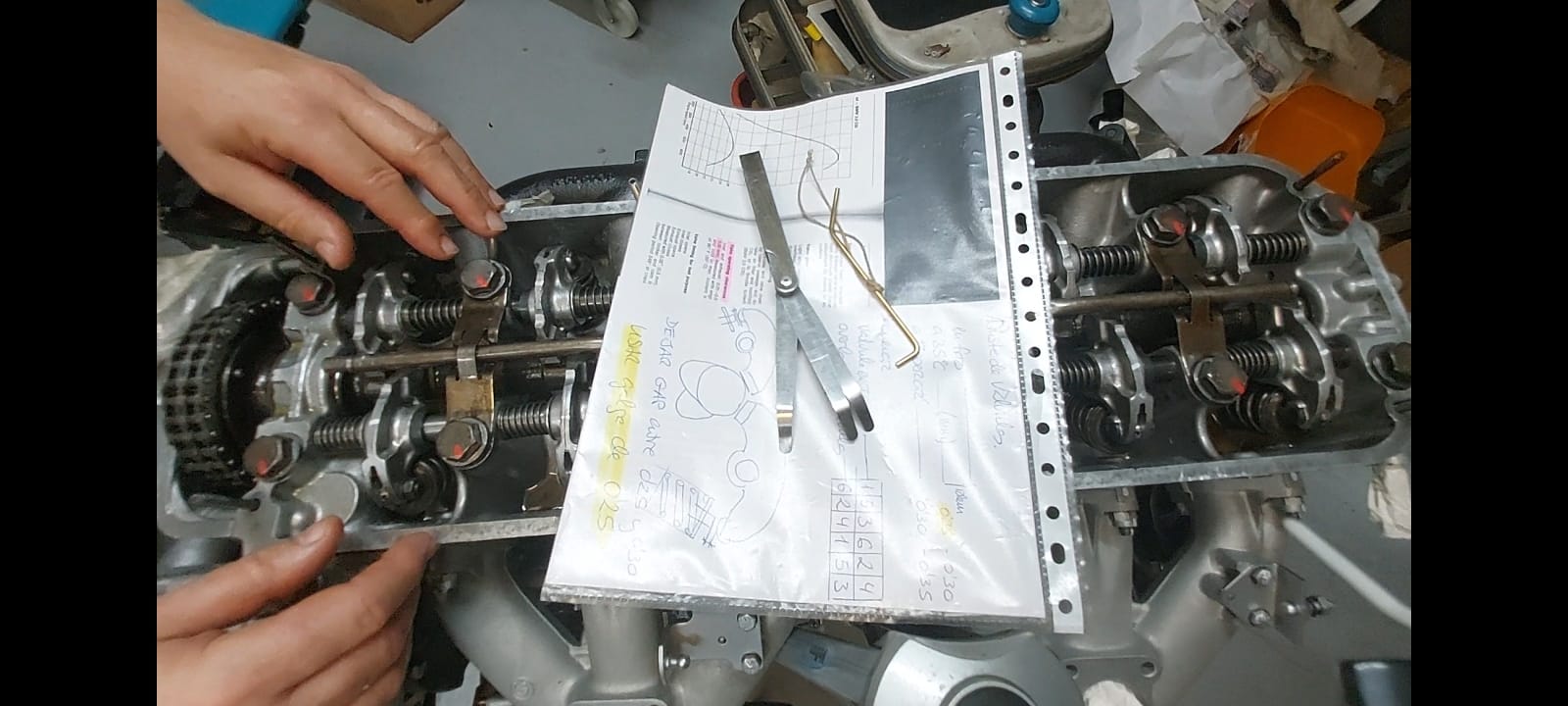

as usual , the bent tool, plus feeler gauges 0,25 and 0,30mm, a torque wrench equipped with special open end (nuts @10N.m), permanent markers, a 36 vase for the crankshaft nut, and an M10 combined wrench

first action was to replace all nuts with new ones from bmw

sequence for cylinder with closed valves in OT, from one to another remember to turn engine always clockwise when looking at engine from the front of the car

i found particularly interesting to proceed this way:

For a given cylinder choose a valve, exhaust or admission both go at 0,25 to 0,30mm gap

place the 0,25 feeler gauge between camshaft and rocker,

Using your less able hand, press the rocker with one finger to ensure gauge trapped and secure

use the bent tool to force the eccentric to contact the valve, apply pressure with a finger of same hand to secure it

With your dominant hand fix the nut, try not to change the setup, not to put pressure on the valve spring

check The gap at the valve end, if 0,25 slides well and 0,30 can’t, that one is good,

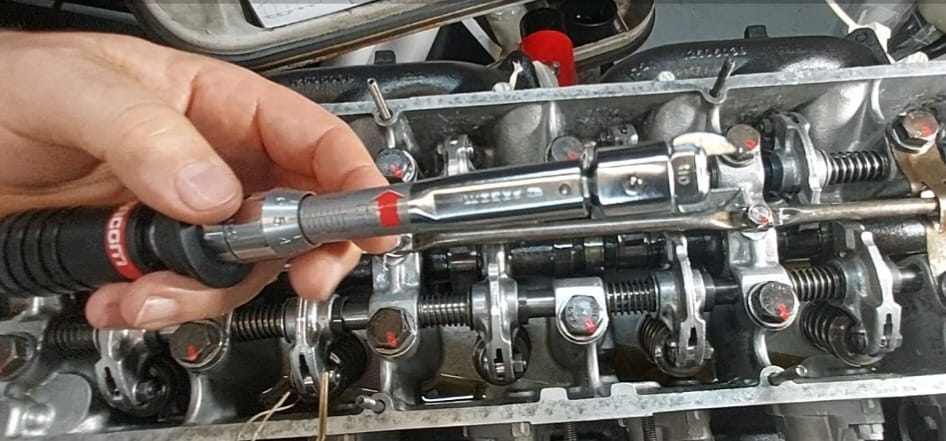

now I use the torque wrench to apply 10N.m to the nut that fix the eccentric

finally paint one mark on the rocker, and move onto the next one

once all cylinders done, I give two turns to the cranckshaft and I check it again, placing a different color mark on each rocker

i found this way much more reliable to get equivalent results at all valves, I know that gap value is not the same at camshaft than at valve, but as the result value is consistent between cylinders and any gap resulting value stands between 0,25 and 0,30 (0,30 gauge does not slide through opening), I am happy with this

As engine is easy to access now I performed a valve gap adjustment

as usual , the bent tool, plus feeler gauges 0,25 and 0,30mm, a torque wrench equipped with special open end (nuts @10N.m), permanent markers, a 36 vase for the crankshaft nut, and an M10 combined wrench

first action was to replace all nuts with new ones from bmw

sequence for cylinder with closed valves in OT, from one to another remember to turn engine always clockwise when looking at engine from the front of the car

i found particularly interesting to proceed this way:

For a given cylinder choose a valve, exhaust or admission both go at 0,25 to 0,30mm gap

place the 0,25 feeler gauge between camshaft and rocker,

Using your less able hand, press the rocker with one finger to ensure gauge trapped and secure

use the bent tool to force the eccentric to contact the valve, apply pressure with a finger of same hand to secure it

With your dominant hand fix the nut, try not to change the setup, not to put pressure on the valve spring

check The gap at the valve end, if 0,25 slides well and 0,30 can’t, that one is good,

now I use the torque wrench to apply 10N.m to the nut that fix the eccentric

finally paint one mark on the rocker, and move onto the next one

once all cylinders done, I give two turns to the cranckshaft and I check it again, placing a different color mark on each rocker

i found this way much more reliable to get equivalent results at all valves, I know that gap value is not the same at camshaft than at valve, but as the result value is consistent between cylinders and any gap resulting value stands between 0,25 and 0,30 (0,30 gauge does not slide through opening), I am happy with this

Last edited:

If you put a .25 feeler gauge between the cam and the rocker, the resulting gap at the valve and rocker would be .315 (.25 x 1.26) and thus out of spec? A .2 gauge at the cam would give you .25 at the valve which is right between the range.

Last edited:

I appreciate your math Steve, for sure you are right, but my experience has been that using 0,25 at the cam, the resulting gap at the valve is something between 0,25 and 0,30, because the 0,30 feeler gauge can not go through that gapIf you put a .25 feeler gauge between the cam and the rocker, the resulting gap at the valve and rocker would be .315 (.25 x 1.26) and thus out of spec? A .2 gauge at the cam would give you .25 at the valve which is right between the range.

I appreciate your math Steve, for sure you are right, but my experience has been that using 0,25 at the cam, the resulting gap at the valve is something between 0,25 and 0,30, because the 0,30 feeler gauge can not go through that gap

what is the last consensus about the best valve gap ?If you put a .25 feeler gauge between the cam and the rocker, the resulting gap at the valve and rocker would be .315 (.25 x 1.26) and thus out of spec? A .2 gauge at the cam would give you .25 at the valve which is right between the range.

should it be a closer one like 0,25 or the wider one like 0,30 ?

i recall that we found that warm engine closes the gap

The gap spec in inches is .010" - .012" and I have always aimed for .010" to minimize but not eliminate valve noise (no noise = too tight). Plus I figure the gap will wear larger over time. Also to consider is supposedly larger gap improves idle quality but hinders high rpm efficiency.

The gap spec in inches is .010" - .012" and I have always aimed for .010" to minimize but not eliminate valve noise (no noise = too tight). Plus I figure the gap will wear larger over time. Also to consider is supposedly larger gap improves idle quality but hinders high rpm

I will note this for the 1000km check

Thanks

Prepare a gasket

Is it the round vent window trim piece?

If you put a .25 feeler gauge between the cam and the rocker, the resulting gap at the valve and rocker would be .315 (.25 x 1.26) and thus out of spec? A .2 gauge at the cam would give you .25 at the valve which is right between the range.

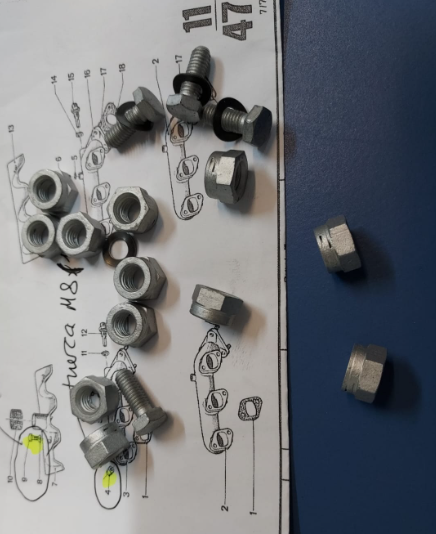

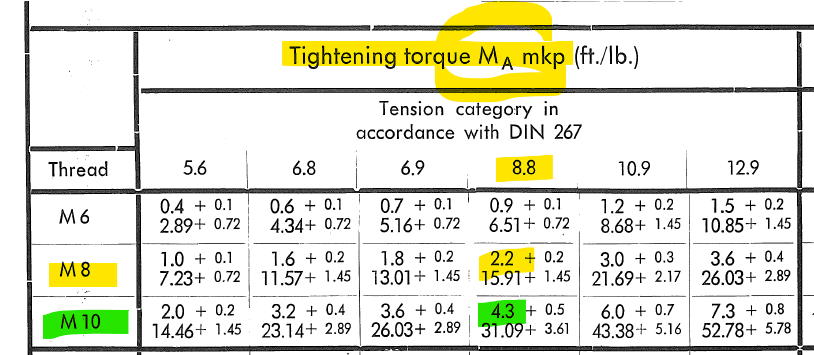

for future questions here it is a graphic aid:

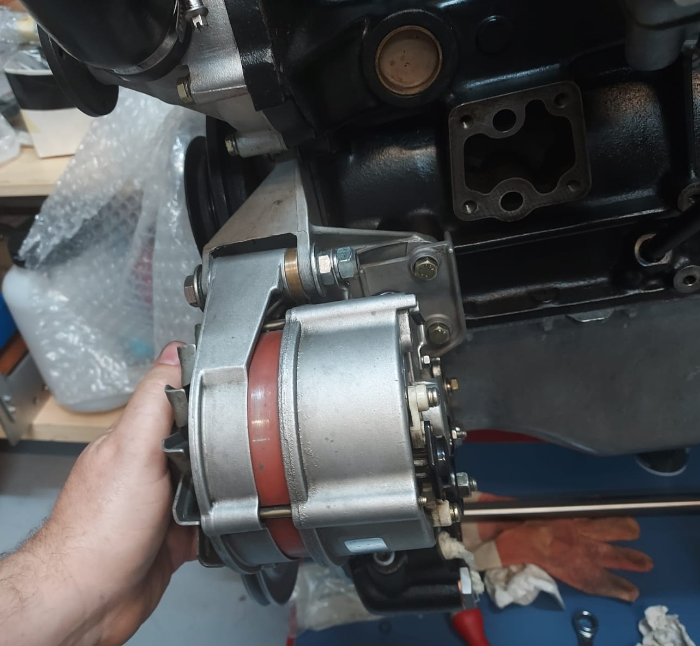

for motor mounts,

LH is M8 in quality 8.8 torque is 22 N.m maximum

RH is M10 in 8.8 torque max is 43 N.m

LH is M8 in quality 8.8 torque is 22 N.m maximum

RH is M10 in 8.8 torque max is 43 N.m

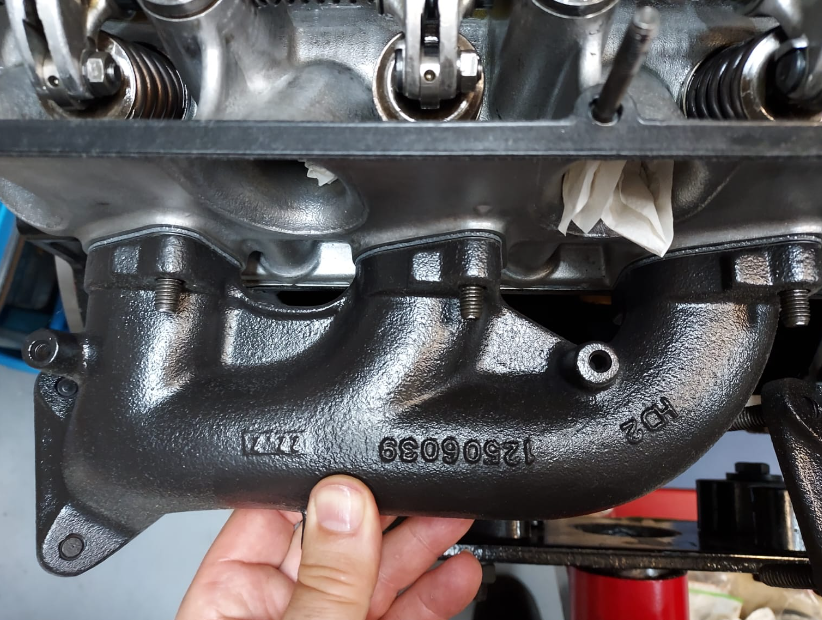

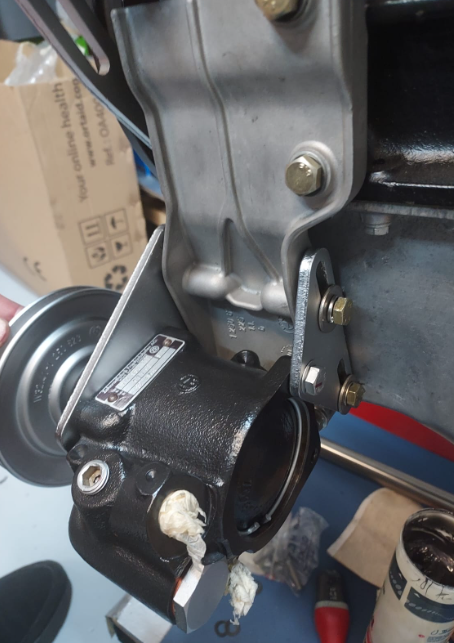

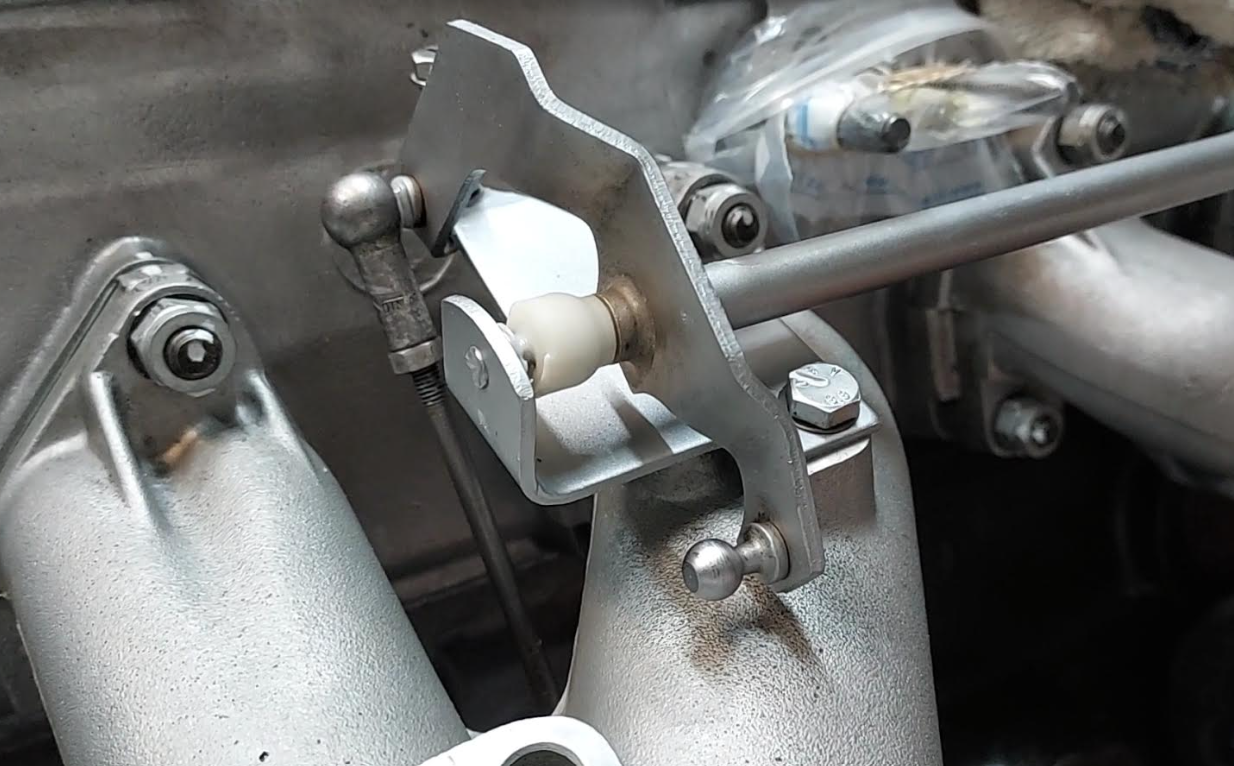

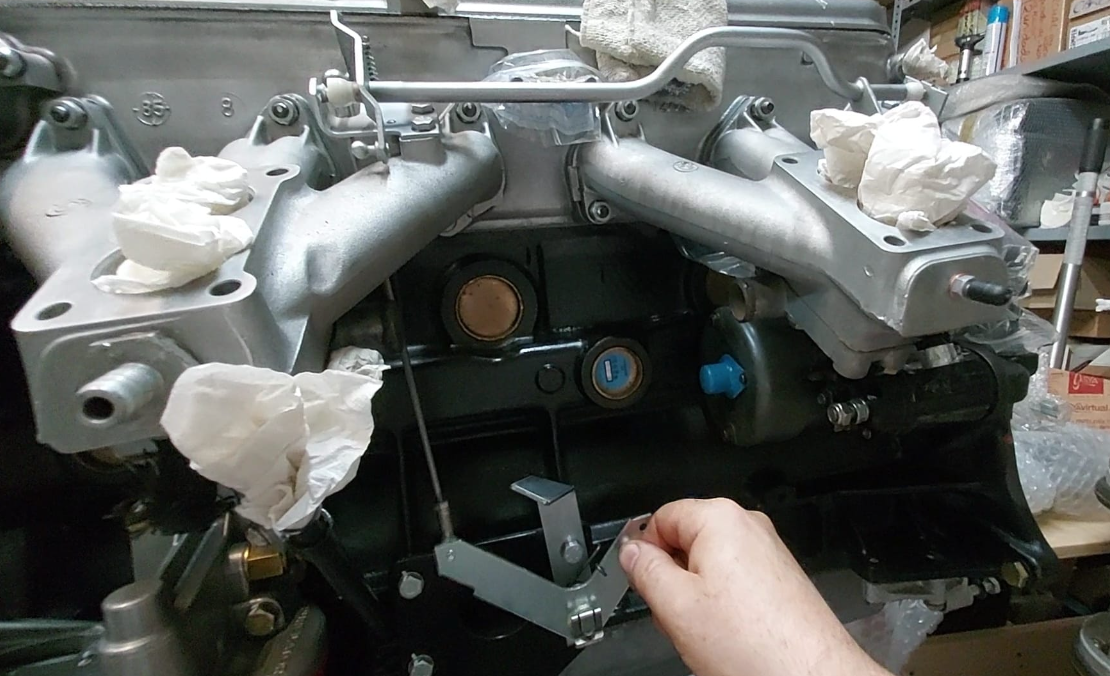

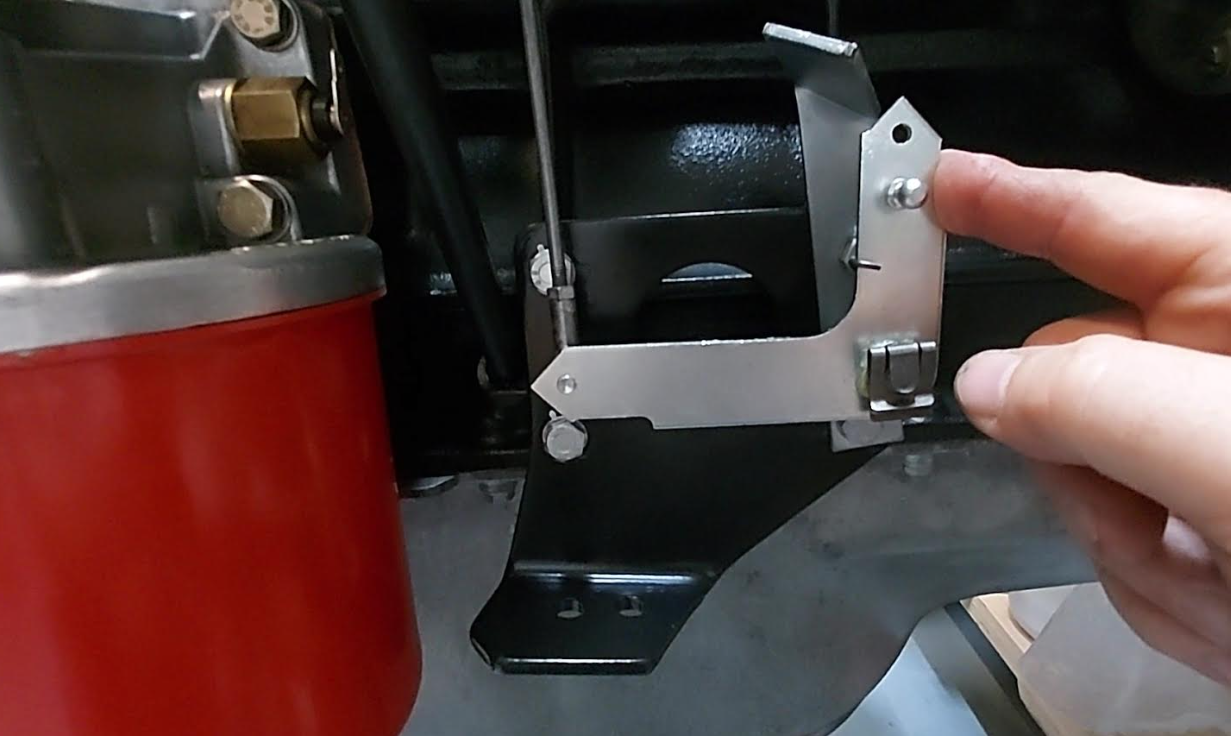

the motor mounts:

i can only set the LH due to RH used for motor stand

and this goes up

i know the stop plate does nothing in my setup, but it looks soo cool; i used 5mm extra length in those two bolts; i know is almost only shear force, but there was enough thread free and depth i couldnt resist (freak overkill)

creeping towards completion

i can only set the LH due to RH used for motor stand

and this goes up

i know the stop plate does nothing in my setup, but it looks soo cool; i used 5mm extra length in those two bolts; i know is almost only shear force, but there was enough thread free and depth i couldnt resist (freak overkill)

creeping towards completion

Last edited:

looks and seems

@Peter Coomaraswamy thanks again for the seats alu trim that you generously sent me twenty years ago, here they are in their full splendour

regards

@Peter Coomaraswamy thanks again for the seats alu trim that you generously sent me twenty years ago, here they are in their full splendour

regards