feelings on the manipulation of the camshaft

being the first time to do this, and with no experts around me when doing it, one of the difficulties is to know if you are doing things right or not

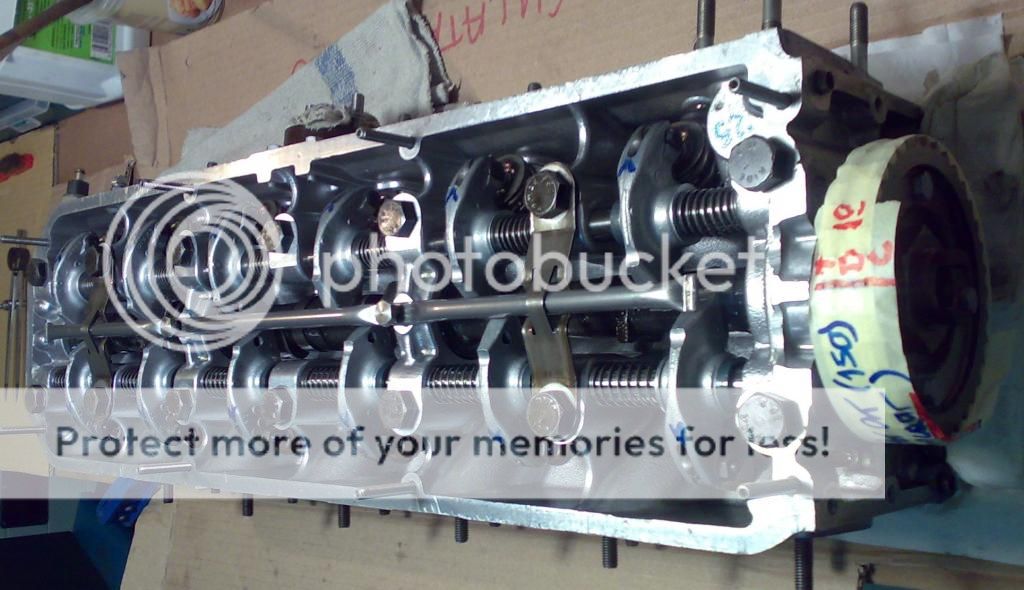

when i assembled the cam together with all the valves, springs and so on, the feeling of turning the cam was pretty bad, it turned easily but not uniformly, somehow it turned at finite steps

what was the reason ? you name it, the clearance adjustment, ...yes, but i didnt knew that...and noone told me neither

so once the tappet clearance is fixed, the cam turns very smoothly, perhaps a bit more effort than before has to be applied, but it turns very nicely

TAPPET CLEARANCE

another issue, i decided to go for 0,25mm tappet clearance, the way to work was, use the 0,25 gauge and let it be loose enough to enter but not as much as allowing the 0,30mm to enter,

believe me, to adjust the clearance is a hard thing to learn, and is learning by doing, it can not be explained, you should feel it, in the first row of valves i repeated the adjusting process several times until i get my hand set to the feeling of the right pressure,

a final check is required rotating the cam and checking all the valves, then a final torque to the nuts to assure the blockage

(if you have set the gap of the distributor points, is a similar issue, feeler gauges are tricky)