You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

my new engine M30B30

- Thread starter deQuincey

- Start date

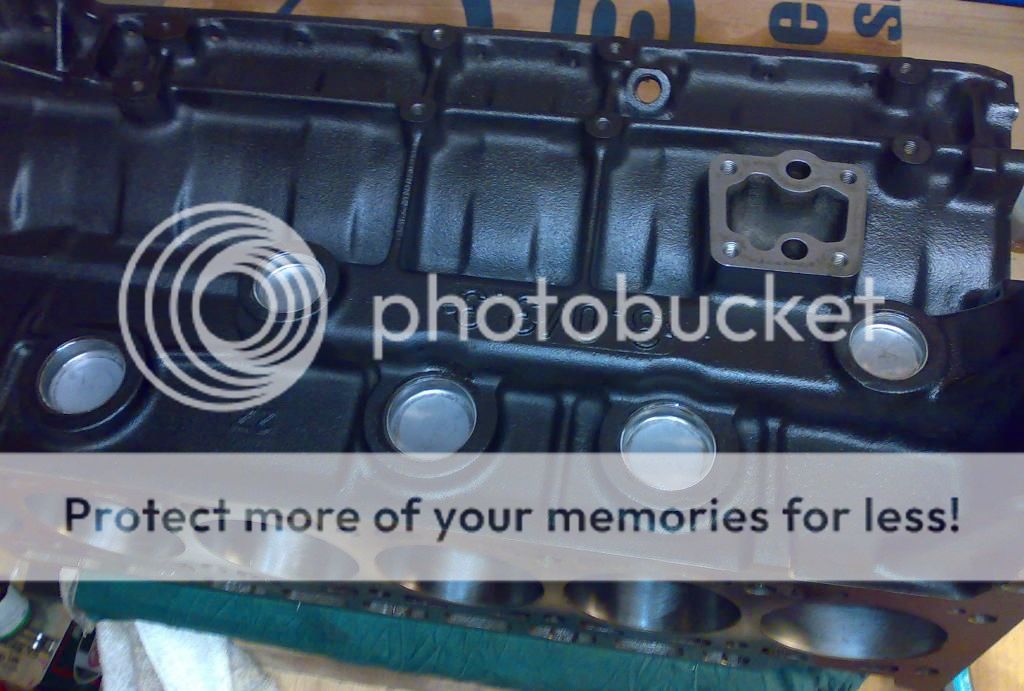

cleaning the block using compressed air and gasoline, despite the block was steammachine cleaned by the shop i found a lot of debriss inside, so i openend all the caps: coolant passage bottom cap, two front and rear oil passage caps, and i used a compressed air tool that allowed me spraying gasoline inside the cavities through a long hose ended in nozzles, you name it, a lot of particles, rests of mud, corroded bits and so on

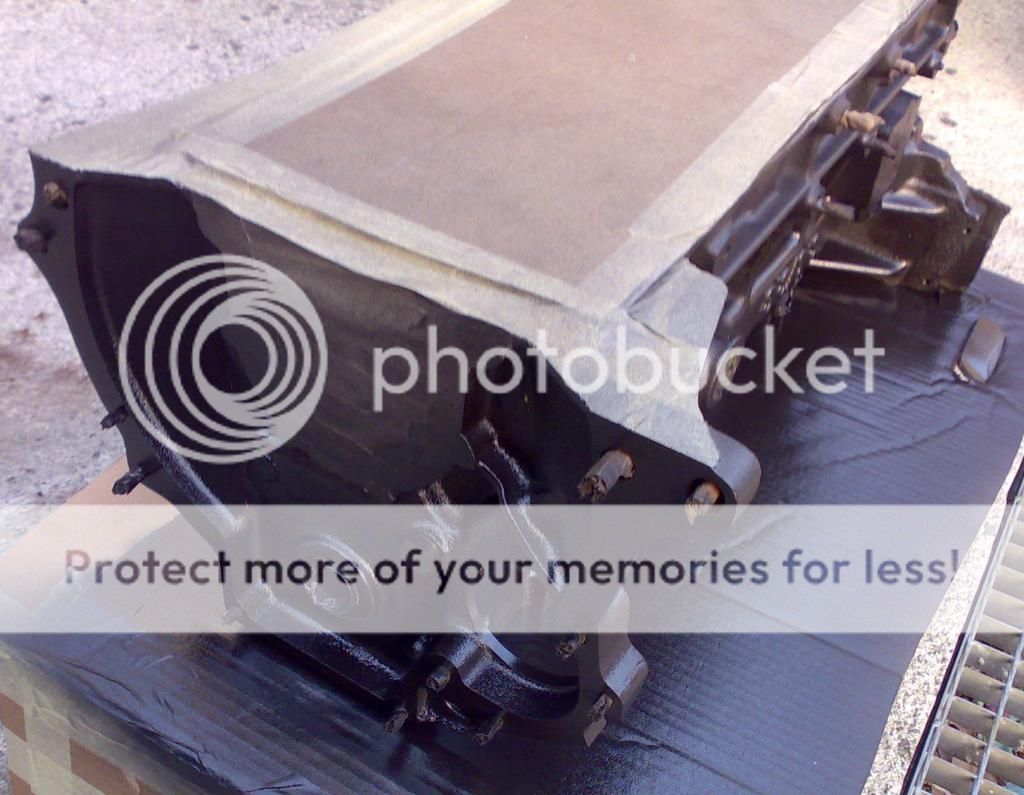

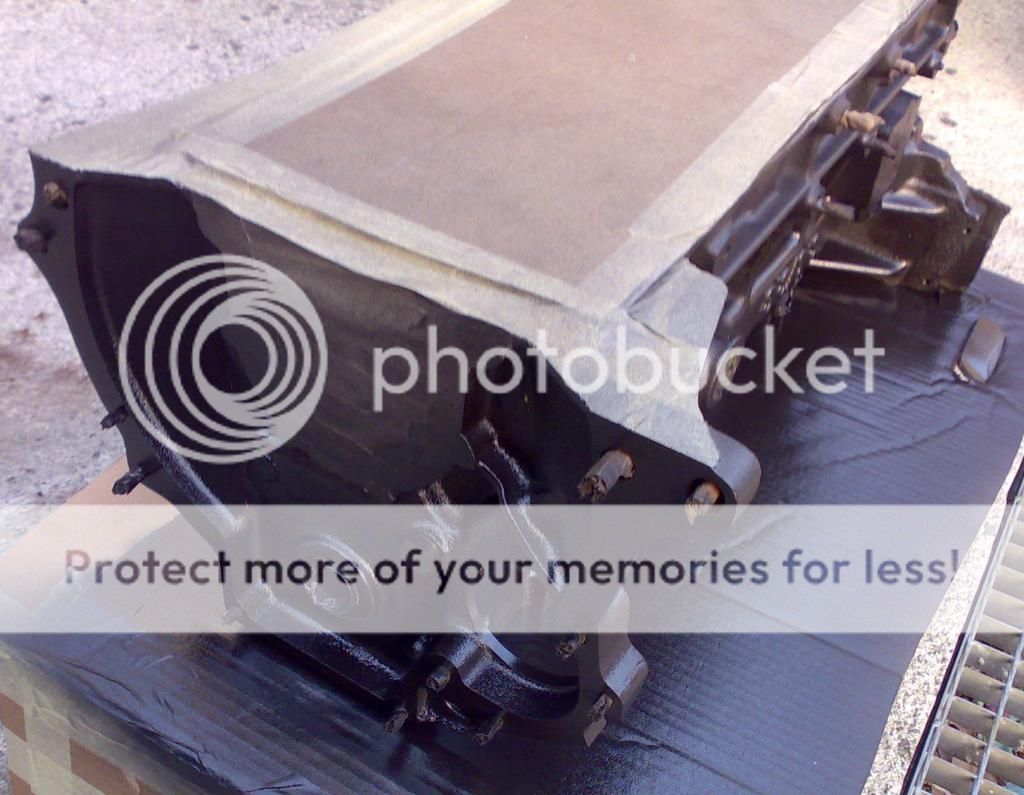

prepare the block for painting, and covering areas

paint in black high temp

prepare the block for painting, and covering areas

paint in black high temp

Last edited:

DerSchwede

Well-Known Member

That engine looks better than new!

Wow very nice as usual

Looks great! Very jealous as you know I have yet to take the head off of mine and figure out what to do. You have to post a video once it is running again.

Looks great! Very jealous as you know I have yet to take the head off of mine and figure out what to do. You have to post a video once it is running again.

certainly i will do that, but it is far away in time yet:lol:

still a lot to do...

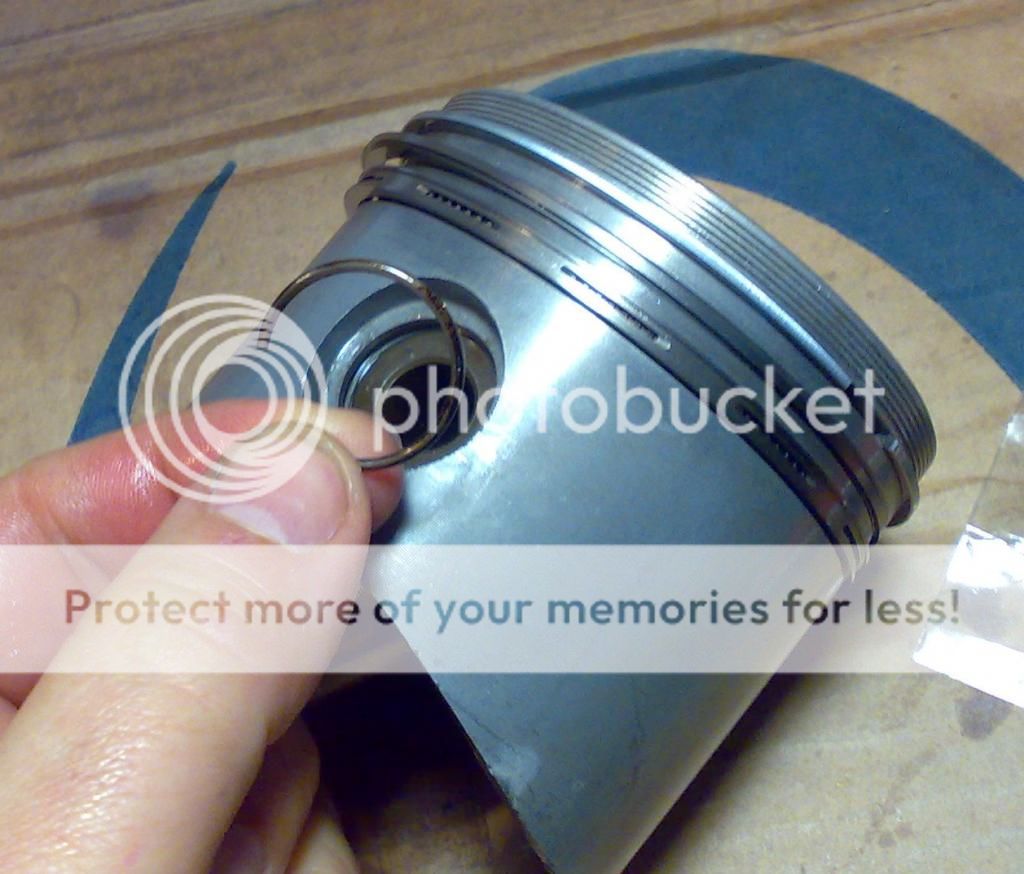

pistons and connecting rods

my brand new, woopy doopy copper mallet, straight from the UK, thanks to the unvaluable help of John

first check each piston and connecting rod, they are identified with numbers (1 to 6), each piston with each rod

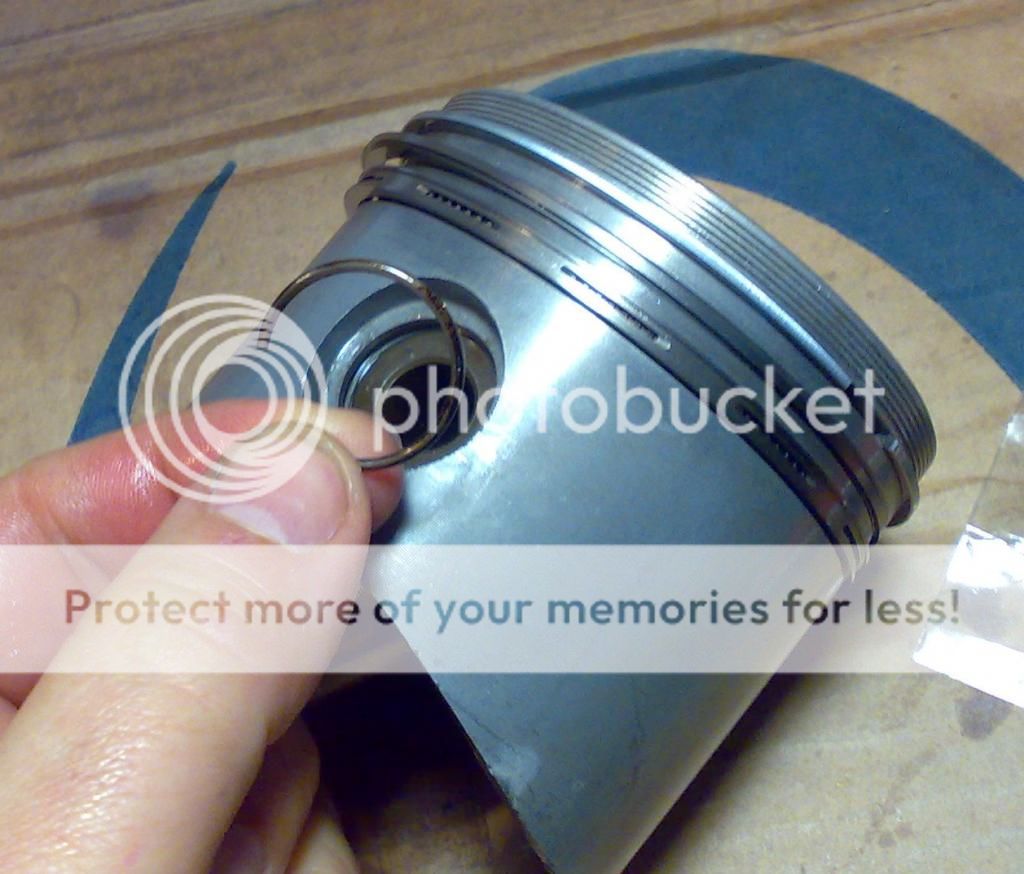

please check this, a finished set, number 3,

the connecting rod oiling hole must face frontwards

see the hole here

to assembly one set, first introduce the shaft,

for that gently oil the shaft and the piston with engine oil, and using only your hand introduce the shaft in its hole slightly balancing the shaft while introducing it, you will be able just to intorduce 1 or 2 mm, but it is enough and very important, when this is done properly, you can hit the shaft softly with a copper hammer made in the UK (not less)

place the connecting rod as explained previously, all connecting surfaces oiled, and gently tap the shaft to continue the mounting process

the last few milimeters will need the help of a spare wrench rod piece

then the circlips, introduce one end

use a thin screwdriver

done

my brand new, woopy doopy copper mallet, straight from the UK, thanks to the unvaluable help of John

first check each piston and connecting rod, they are identified with numbers (1 to 6), each piston with each rod

please check this, a finished set, number 3,

the connecting rod oiling hole must face frontwards

see the hole here

to assembly one set, first introduce the shaft,

for that gently oil the shaft and the piston with engine oil, and using only your hand introduce the shaft in its hole slightly balancing the shaft while introducing it, you will be able just to intorduce 1 or 2 mm, but it is enough and very important, when this is done properly, you can hit the shaft softly with a copper hammer made in the UK (not less)

place the connecting rod as explained previously, all connecting surfaces oiled, and gently tap the shaft to continue the mounting process

the last few milimeters will need the help of a spare wrench rod piece

then the circlips, introduce one end

use a thin screwdriver

done

Joder, teniamos seis cilindros!

(untranslatable reaction).

(untranslatable reaction).

Joder, teniamos seis cilindros!

(untranslatable reaction).

you want a tapas of ham and cilantro????

Joder, teniamos seis cilindros!

(untranslatable reaction).

good one, better keep google translator out of reach or the thread will be +18 rated due to strong languaje

another one for your consideration: "esto es la hostia !"

DerSchwede

Well-Known Member

Which pistons did you decide to go with?

Looks really good BTW..

I'm still waiting for the new rocker arms, though that could take another couple of weeks as they were not in stock at BMW !

Cheers

A

Looks really good BTW..

I'm still waiting for the new rocker arms, though that could take another couple of weeks as they were not in stock at BMW !

Cheers

A

Which pistons did you decide to go with?

Looks really good BTW..

I'm still waiting for the new rocker arms, though that could take another couple of weeks as they were not in stock at BMW !

Cheers

A

Hi A. thanks

those are the original pistons at +0,25, i renewed the rings as per post #71

weekend continuation

working on the head,...

rear cover has a tricky point, the seal of the top right bolt:

to explain the process i use, take the coolant hose: clean the surface

components: a wire brush, loctite positioning paste, bolts

coat the gasket with the positioning paste, that will let you position a vertical gasket perfectly

do the bolts sequentially

working on the head,...

rear cover has a tricky point, the seal of the top right bolt:

to explain the process i use, take the coolant hose: clean the surface

components: a wire brush, loctite positioning paste, bolts

coat the gasket with the positioning paste, that will let you position a vertical gasket perfectly

do the bolts sequentially

tappet clearance

i will fix cold tappet clearance to 0,25mm, it is the minimum value established in the blue books, and as heat increases the clearance, i will set to minimum value

the famous tool and a 0,25 conviniently bent blade gauge

this is probably unnecessary, but is good to remember, you fix the clearance when the rocker is facing the cylindric side of the camshaft

see a detail:

for CYL 1 in TDC CYL6 is in overlapping, so you adjust the clearance of CYL 1

the setup: you need two hands (fortunately)

detailed sequence:

first loose the nut and place the 0,25 gauge between the cam and the valve,

then using the special tool place the eccentric wheel until everything is in contact: rocker with camshaft, eccentric with gauge and valve, do not overpressure it

now maintain a little pressure in the special tool and grab the 10mm key to fix the nut, slightly do it and when you start to feel resistence stop

remove the special tool and the gauge and press the rocker against the camshaft to avoid distortion over the eccentric, and now do the nut to block it

this last step might seem odd, but if you do not proceed this way you will distort the clearance adding pressure to it and thus reducing the gap

i will fix cold tappet clearance to 0,25mm, it is the minimum value established in the blue books, and as heat increases the clearance, i will set to minimum value

the famous tool and a 0,25 conviniently bent blade gauge

this is probably unnecessary, but is good to remember, you fix the clearance when the rocker is facing the cylindric side of the camshaft

see a detail:

for CYL 1 in TDC CYL6 is in overlapping, so you adjust the clearance of CYL 1

the setup: you need two hands (fortunately)

detailed sequence:

first loose the nut and place the 0,25 gauge between the cam and the valve,

then using the special tool place the eccentric wheel until everything is in contact: rocker with camshaft, eccentric with gauge and valve, do not overpressure it

now maintain a little pressure in the special tool and grab the 10mm key to fix the nut, slightly do it and when you start to feel resistence stop

remove the special tool and the gauge and press the rocker against the camshaft to avoid distortion over the eccentric, and now do the nut to block it

this last step might seem odd, but if you do not proceed this way you will distort the clearance adding pressure to it and thus reducing the gap

Last edited:

a question, H E L P !

CAN YOU PLEASE HELP ON THIS ?

i would like to know which is the best way to block the camshaft to do the big nut

we are speaking about a torque of 150 N.m, so it is not negligible how to block the shaft to allow the nut to be torqued correctly without damaging the shaft

any help will be appreciated. thanks

CAN YOU PLEASE HELP ON THIS ?

i would like to know which is the best way to block the camshaft to do the big nut

we are speaking about a torque of 150 N.m, so it is not negligible how to block the shaft to allow the nut to be torqued correctly without damaging the shaft

any help will be appreciated. thanks