Mark,

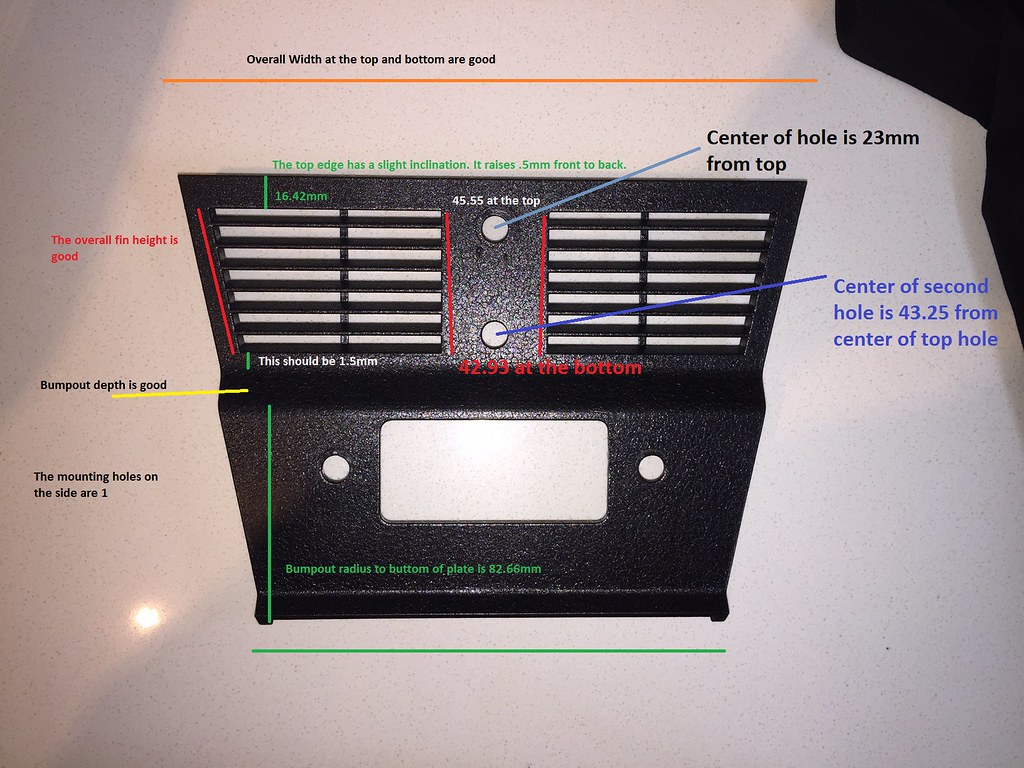

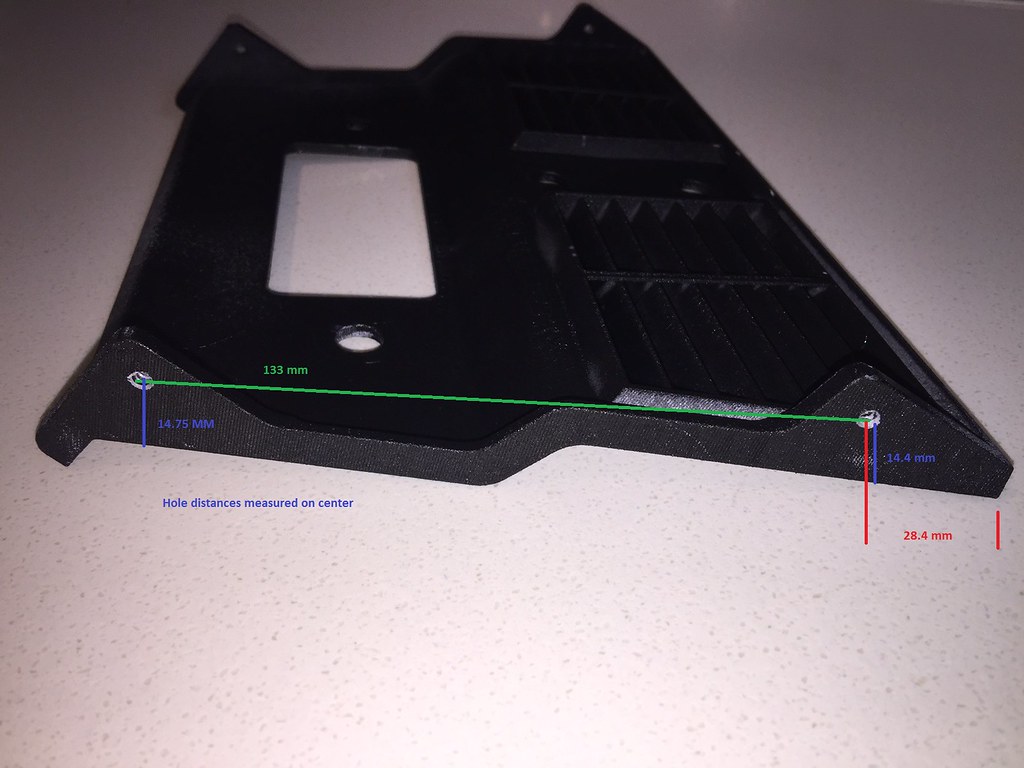

I am sorry to have to be the bearer of bad news, but unfortunately we have received a trademark infringement notice for your listing of E9 AC Console Grille - Driver

The notice claims that your product title and/or description infringes the rights of Bayerische Motoren Werke AG and BMW of North America, LLC (“BMW”), who own the trademarks related to BMW automobiles. The notice does not claim that your model itself is infringing.

BMW requests that you change your listing and/or description in order to avoid suggesting a formal affiliation with BMW. For example, a listing of “BMW widget” can be revised to state “Widget for BMW” to make it clear that the widget itself does not come from BMW directly.

Please reply to this notice within seven (7) days to confirm that you have modified your listing and/or description accordingly. If we have not heard from you within that time we will be forced to remove the model from your account.