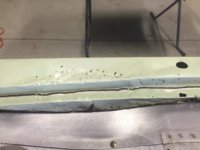

Thanks guys..........little over 1 mm sheet metal in that area same as the surrounding metal. Likewise any other areas worked on identical thickness material to suit. No skimping

MIG welded in that particular area.....too hard to get TIG welder in there. TIG welded everywhere else especially panels as you can panel beat TIG welding. Hope to have engine photos next week as engine being assembled as we speak.

MIG welded in that particular area.....too hard to get TIG welder in there. TIG welded everywhere else especially panels as you can panel beat TIG welding. Hope to have engine photos next week as engine being assembled as we speak.