Wladek, I think you are absolutely right in plating the parts before powder coating. I have seen so many powder coated parts rust - possibly worse than painted parts. I personally feel that a powder coated finish often does not bond as well as a fluid applied coating. And in this case, the powder coated pieces will rust quicker and worse than anything painted. I've seen suspension parts, springs, wheels, center caps, frames, and chassis systems - all powder coated - and all rust terribly. You are doing great work!Zinc plating for most of the parts was made by me for additional rust protection in future.

I know most of people would say that powder coating itself is good or very good protector, but i am little bit skeptical

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

72' Fjord CSI resto

- Thread starter Wladek

- Start date

-

- Tags

- restoration list

Wladek

Well-Known Member

From what i read before i started my own powder coating was, that surface preparation is most important process before starting any powder coating.Wladek, I think you are absolutely right in plating the parts before powder coating. I have seen so many powder coated parts rust - possibly worse than painted parts. I personally feel that a powder coated finish often does not bond as well as a fluid applied coating. And in this case, the powder coated pieces will rust quicker and worse than anything painted. I've seen suspension parts, springs, wheels, center caps, frames, and chassis systems - all powder coated - and all rust terribly. You are doing great work!

As you mentioned - if under the coating will be any rust it will be disaster, because powder coat itself will do nothing with rust it only close the moisture inside; the same thing is when surface wasn't properly degreased, or wasn't heated before powder coating process.

Another thing, from my little experience is that powder coated surface is very resistant on scratches, moisture, acids but is pretty fragile on pointed impacts/hits, so let just say accidental hit of stone or hammer can cause local pealing of the coating & in such moments second level protection will be on zinc.

Same experience for me.

Powder coating alone is not the route to follow for parts that are abused e.g. under the car. A single chip in the powder coat is all it takes for water to enter, start a rust spot and grow, unseen under the powdercoat layer.

I also treat everything before powdercoat if they get a beating during use.

I choose between galvanic zinc plating or Aluminium-Zinc thermal spraying for under body parts. It is a ,2 to 0,5 mm thick and an immensely tough coating. You wont ever manage to chip the Alu-zinc coating with just road gravel; it's too tough. It is a process where the metal in form of a wire or powder is fed through a nozzle where is it heated up by a burning gas (usually acetylene). The droplets of Alu+Zinc then impact the surface to be coated and solidify on impact. I had my rear subframe and stub axles treated that way. Really happy with it.

Powder coating alone is not the route to follow for parts that are abused e.g. under the car. A single chip in the powder coat is all it takes for water to enter, start a rust spot and grow, unseen under the powdercoat layer.

I also treat everything before powdercoat if they get a beating during use.

I choose between galvanic zinc plating or Aluminium-Zinc thermal spraying for under body parts. It is a ,2 to 0,5 mm thick and an immensely tough coating. You wont ever manage to chip the Alu-zinc coating with just road gravel; it's too tough. It is a process where the metal in form of a wire or powder is fed through a nozzle where is it heated up by a burning gas (usually acetylene). The droplets of Alu+Zinc then impact the surface to be coated and solidify on impact. I had my rear subframe and stub axles treated that way. Really happy with it.

Last edited:

Wladek

Well-Known Member

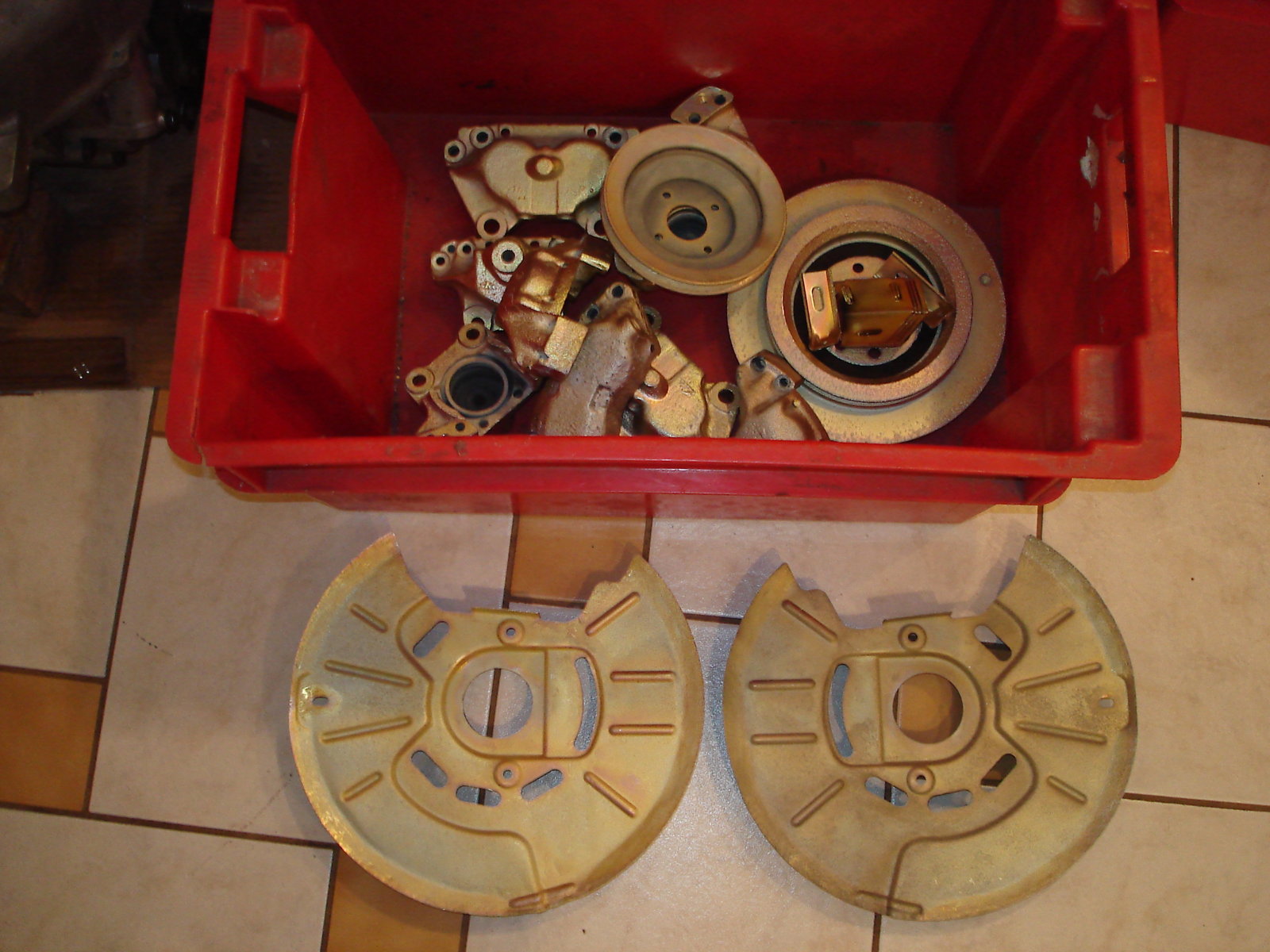

Today received some things from zinc plating - as for now i have enough of zinc plating, need a brake. I see that the company that does it, is doing it worse and worse, the waiting period has been extended three times, and prices are getting higher and higher. But unfortunately they have local monopoly.

Also made some windows mechanism springs & pedal springs blackening

And for the test made chain cover natural colour anodizing - hate it:eek: will have to powder coat it or make something else.

That dark grey colour of anodizing is because of poor quality aluminium, which contain a lot of carbon impurities in the casting. Will see, maybe next time will ask them to make silver finish.

Also made some windows mechanism springs & pedal springs blackening

And for the test made chain cover natural colour anodizing - hate it:eek: will have to powder coat it or make something else.

That dark grey colour of anodizing is because of poor quality aluminium, which contain a lot of carbon impurities in the casting. Will see, maybe next time will ask them to make silver finish.

Hi Wladek, Is their quality of plating getting worse? Or is it just the slower timing and higher costs? The timing and costs are bad enough - just curious if the quality is also affected. Still looks great in the photos (except for that natural anodizing).I see that the company that does it, is doing it worse and worse

Wladek

Well-Known Member

I have the impression that the coating of zinc is getting thinner, besides it is done inaccurately. At the beginning it was better, faster & cheaper.Hi Wladek, Is their quality of plating getting worse? Or is it just the slower timing and higher costs? The timing and costs are bad enough - just curious if the quality is also affected. Still looks great in the photos (except for that natural anodizing).

For the zinc plating from first photo of these thread i payed about the same amount as for today's zinc plating - you can compare.

When i started zinc plating, delivered items where ready after 4-5 working days, for today's i waited for 11 working days.

I will galvanize anyway, i don't have any other better choice, but I will limit them to larger parties.

Probably not the big deal for most of people on this forum, but this week i made my first steps with home powder coating.

Pretty satisfied with final results. Made a mistake with heater cover - layer could be little bit thicker, so could cover areas from rust pitting. But hope in future to not repeat that mistake.

Wiper mechanism frame was powder coated with structural powder, so it might look like it have rust pitted surface, but actually it's not.

View attachment 42136

Do you have the colour code for the red filter housing?

I saw 2 upper radiator mounts in one of the photos. Is this standard, is your car RHD, difference between CSI and CS?. I just re-did this on my 73 CS and only one is removable, the other is welded in place. Just curious.

Only passenger side is removable, they are satin black.I saw 2 upper radiator mounts in one of the photos. Is this standard, is your car RHD, difference between CSI and CS?. I just re-did this on my 73 CS and only one is removable, the other is welded in place. Just curious.

Wladek

Well-Known Member

RAL 3020Do you have the colour code for the red filter housing?

My car is LHD & i have standard mounts (one removable & one welded), second one is just spare part.I saw 2 upper radiator mounts in one of the photos. Is this standard, is your car RHD, difference between CSI and CS?. I just re-did this on my 73 CS and only one is removable, the other is welded in place. Just curious.

RAL 3020

My car is LHD & i have standard mounts (one removable & one welded), second one is just spare part.

Thanks for the code, will order some tomorrow as we've been painting them black on restorations.

Good work Wladek.....you're more anal then me  ............my main engine parts I ceramic coated including the exhaust headers.............will post them up when engine is assembled.

............my main engine parts I ceramic coated including the exhaust headers.............will post them up when engine is assembled.

Marc-M

Well-Known Member

Hi

Are u going to powder coat over the zinc plating? - just that when I have had to paint over zinc plating (galvanized RSJs in buildings) you have to put an degreaser acid/ etch or similar to get a good bond between the zinc and the paint/ powder..

Not to sure about the chemistry on how it works....

I could be wrong ... but its worth checking before powder coating everything.

Are u going to powder coat over the zinc plating? - just that when I have had to paint over zinc plating (galvanized RSJs in buildings) you have to put an degreaser acid/ etch or similar to get a good bond between the zinc and the paint/ powder..

Not to sure about the chemistry on how it works....

I could be wrong ... but its worth checking before powder coating everything.

Wladek

Well-Known Member

Sorry Guys that was no updates for a long time, but it doesn't mean that no work was done.

First half of 2018 was continuing some purchases like new body repair parts, front & rear axle (Bilstein B6), stainless exhaust (W&N) + headers (NOS Supersprint)... etc.

Some stainless bolts, screws, washers for the engine & body

Already rebuild some hydraulic & brake parts. Started rebuilding my both CSI engines (waiting for 12x sets of piston rings +0,50mm (my good friend have them already, but still abroad, couldn't find any in Poland), gap with +0,25mm was 0,55-0,6mm (so off scale). One of the cylinder head will need some more love than other one. Have propblem with cranckshaft screw, already broke one 1/2" wrench

Some more zinc plating (not all - forgot to made photo's) - starter parts, engine/injection parts, calipers, door windows rails etc. Not very pleased with zinc plating of calipers - will have to make some corrections, probably rookie made this part of zinc plating (unfortunately for me).

Started my body repair with doors, because was afraid of them most of all. Previous owner started some body welding, but his work is/was pretty shitty & doors weren't good lined with fenders, so...

First half of 2018 was continuing some purchases like new body repair parts, front & rear axle (Bilstein B6), stainless exhaust (W&N) + headers (NOS Supersprint)... etc.

Some stainless bolts, screws, washers for the engine & body

Already rebuild some hydraulic & brake parts. Started rebuilding my both CSI engines (waiting for 12x sets of piston rings +0,50mm (my good friend have them already, but still abroad, couldn't find any in Poland), gap with +0,25mm was 0,55-0,6mm (so off scale). One of the cylinder head will need some more love than other one. Have propblem with cranckshaft screw, already broke one 1/2" wrench

Some more zinc plating (not all - forgot to made photo's) - starter parts, engine/injection parts, calipers, door windows rails etc. Not very pleased with zinc plating of calipers - will have to make some corrections, probably rookie made this part of zinc plating (unfortunately for me).

Started my body repair with doors, because was afraid of them most of all. Previous owner started some body welding, but his work is/was pretty shitty & doors weren't good lined with fenders, so...

Last edited:

Wladek

Well-Known Member

Yes, some parts are already powder coated.Hi

Are u going to powder coat over the zinc plating? - just that when I have had to paint over zinc plating (galvanized RSJs in buildings) you have to put an degreaser acid/ etch or similar to get a good bond between the zinc and the paint/ powder..

Not to sure about the chemistry on how it works....

I could be wrong ... but its worth checking before powder coating everything.

Yes, i use degreaser before powder coating, also parts are warmed up immediately before powder coating (so was no bubbles).

I envy a guy who can say the door alignment is the worst part of the bodywork on their coupe.tarted my body repair with doors, because was afraid of them most of all.

Wladek

Well-Known Member

I started with doors - to see how much previous owner screw up in whole body line.I envy a guy who can say the door alignment is the worst part of the bodywork on their coupe.The work looks wonderful!!! Aluminum door skins?

Luckily for me - he just cut some parts of rear & front fenders (didn't cut them in main welding points/mounts), so body line in general "is". So, after i will finally glue in door skins, i think i can start normally from rear end & move forward.

Yes, some time ago i decided that i will have aluminium doors, boot lid; don't know yet if i will be able to find good specialist for bonnet skin.

Last edited:

Regarding lighter weight panels, I met a guy that makes carbon fiber body panels (among other things) for SEMA cars, etc. Part of me was thinking of pinging the group to see how much interest there might be in a run of hoods and trunk lids. Frankly, I am not even sure I'd be interested in that. But, of course, doing (1) is quite expensive because the mold time is where the cost is at. But once a mold is made, the more your make, the less they are. I kind of think carbon fiber hoods are a bit too... "custom" for our coupes. But the weight savings...don't know yet if i will be able to find good specialist for bonnet skin.

Wladek

Well-Known Member

I went with aluminium door skins & want to put aluminium boot lid, because e9's had this parts in general (CSL).

I think it will be more like a little bonus, which should not interfere, even that it is CSI.

I think it will be more like a little bonus, which should not interfere, even that it is CSI.

Wladek

Well-Known Member

Little update.

This week some powder coating was made

Reassembled headlight frames

Headlights where also cleaned inside (where dusted) - if someone is interested in the recipe:

1. Warm distilled water mixed with dish soap & glass beads

2. Some shaking

3. Flushing with warm distilled water couple times, till soap will be full out.

4. Some shaking to drain rest of moisture/water

5. Owen 45-50C for ca. 15 minutes, lamps upside down so moisture can evaporate.

Some rebuild and reassembled master & slave cylinders

This week some powder coating was made

Reassembled headlight frames

Headlights where also cleaned inside (where dusted) - if someone is interested in the recipe:

1. Warm distilled water mixed with dish soap & glass beads

2. Some shaking

3. Flushing with warm distilled water couple times, till soap will be full out.

4. Some shaking to drain rest of moisture/water

5. Owen 45-50C for ca. 15 minutes, lamps upside down so moisture can evaporate.

Some rebuild and reassembled master & slave cylinders

Last edited: