One of the additional challenges we weekend warriors are facing, on top of only having limited time (one day a week when I'm lucky), is that we also have to spend a lot of time making tools or devising different solutions to make up for the lack of a permanent setup.

I have been spending the last couple of weekends preparing for a transmission conversion. In order to get as much working room as possible, I put the car on the highest settings of my jack stands, with a couple of 2x4s underneath them. Everytime I went under the car I kept thinking that since we are in earthquake country here it wouldn't take much for me to get flattened like a pancake if a decent one decided to happen at that time. On top of that I wasn't convinced there would be enough room to roll the slushbox out of there once it is on the transmission jack.

So I decided to work on a safer and also higher setup. One way to do that is to use the wheels as main support whenever possible. So I found these light weight wheel "cribs" which lift the wheel itself 12 inches off the ground. Kind of expensive at about $100 for two but, being made out of high density foam, they are super light easy to deal with. Since my rear wheels are still on the car, I bought one pair of those "Race Ramps Wheel Cribs" cribs for them.

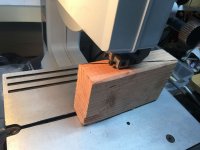

One bit of challenge is that when you jack the car up the wheels hang as low as they can on the unloaded suspension. So you have to jack the car up way higher than would seem safe, put several 2x4 on top of the jack stand so you can free up the floor jack to lift the half shaft until you can slide the crib under the wheel.