OK, summer months were a bit slow, but we are moving on. Slowly but surely.

We scanned now my car, the bare body with already changed sill and one wheelwell. As somewhat suspected, when comparing the 2 scans, we found out some of the measurements from the "good" car were off on mine and by as much as 15mm (~1/2 inch). That is nowhere in acceptable range, but luckily we have modern 3D tech and computer programs to mend that. We drew up a sturdy rig that would attach to my car at specific points and would enable to reinstall the wheelwell etc bits later on in exact locations. Better than using a Celette bodybench, for which E9 attachments are really hard if not impossible to find and which do not really satisfy fully anyway...

My car's body skeleton scanned as-is:

My car scanned as-is, another angle:

Here is the "good car", with measurment points

And mine measured at the same points. You can also see the previous owner repaired the floor on one side - we will cut it out and restore with original panels ofcourse.

So overlaying the 3D models on top of each other and comparing measurements, we did find mine was no good. Here is an example of the 2 models on top of each other showing the difference with rear wheelwell and shock mounts:

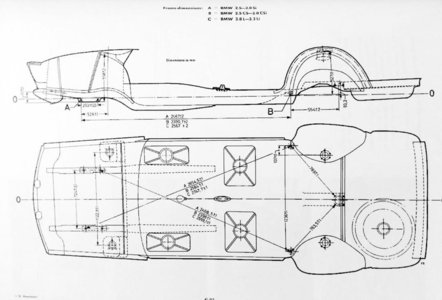

And this is how we will correct it. The rig we drew up is seen on the following images and is currently being lasercut and bent at a speciality shop.

For the front of the car, we will construct a similar rig to make sure everything is later as it should be.

PS! just an idea about which I will have to talk to my constructor about, but if there would be interest, we could also offer the rigs later to others restorers

. As 3D models or ready made.