xjan99

Well-Known Member

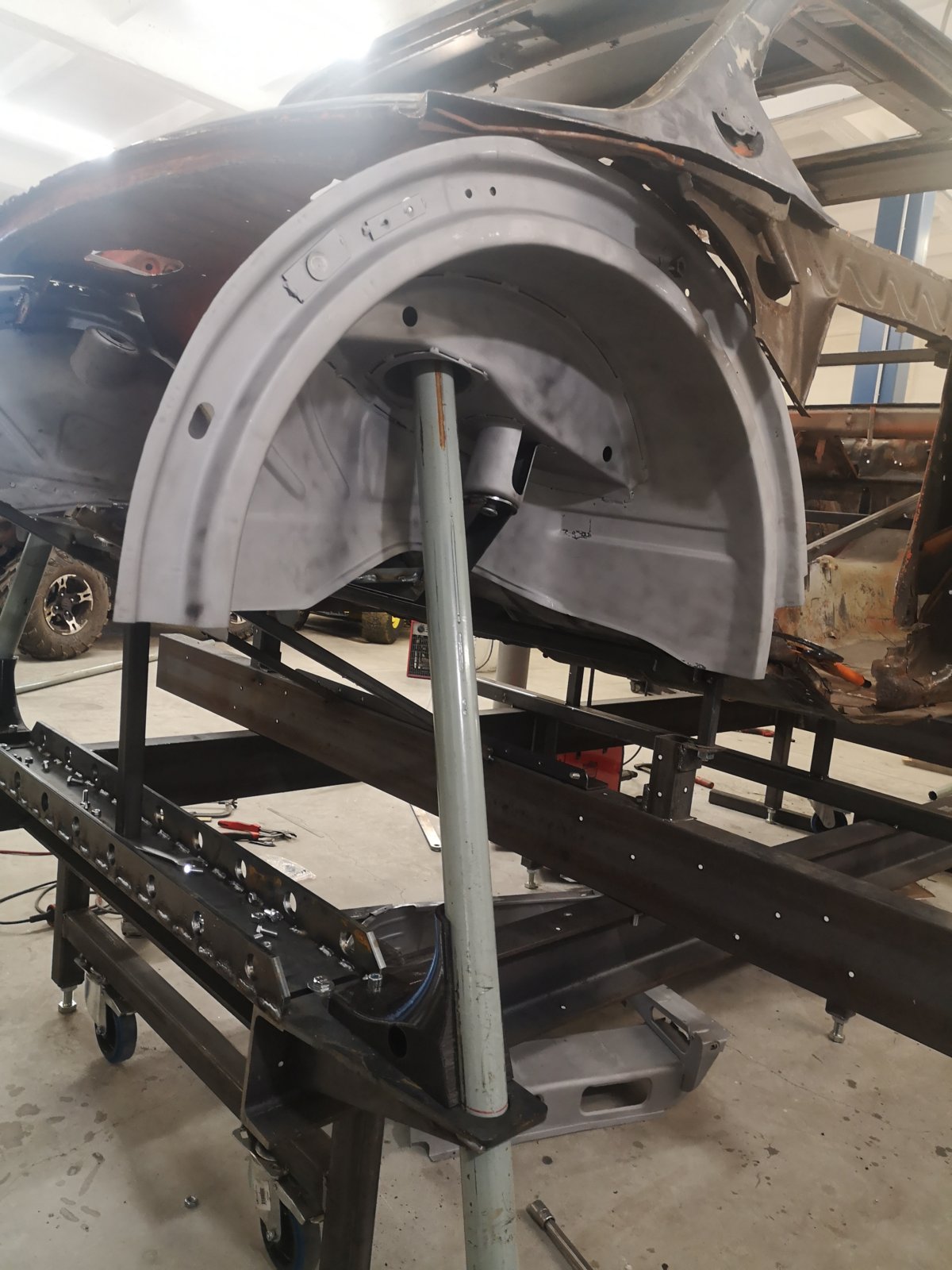

A few more process photos.

The additional rigs for front and rear were assembled and attached to the car.

We also found out the previous owner's work attaching the inner sill and inner-outer wheel well were done incorrectly, so had to reopen the wheel well parts and repair them.

But it seems, now finally some parts are ready to go back in. They all need repairs, cleaning etc before.

The additional rigs for front and rear were assembled and attached to the car.

We also found out the previous owner's work attaching the inner sill and inner-outer wheel well were done incorrectly, so had to reopen the wheel well parts and repair them.

But it seems, now finally some parts are ready to go back in. They all need repairs, cleaning etc before.

Last edited: