I was painting and plating some parts today, which I'll share photos of once I finish up this batch. But with the snow melted, I re-discovered some early test pieces that I'd plated just over 4 months ago. These were freshman attempts, before I'd dialed in my system and process. But I still thought it was worthwhile to do my own corrosion test. I set these samples down directly on the dirt just over 4 months ago. Shortly after, they were covered with about 2 feet of snow. I just examined them this morning. They look pretty good. No evidence of corrosion on the top surfaces at all. The yellow chromate converted pieces look great on the bottom, too. The silver ones may be showing signs of early corrosion - or staining - on the bottom. These are blue chromate converted which have a higher salt spray rating. I don't know how that translates to laying in the dirt. I also don't know how "direct dirt contact" translates to actual automotive use. Presumably, the parts on the car would never be laying in the dirt for 4-months (at least I hope not). I'll continue to keep these out there as long as my wife will tolerate it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Raven e9 project

- Thread starter autokunst

- Start date

-

- Tags

- restoration list

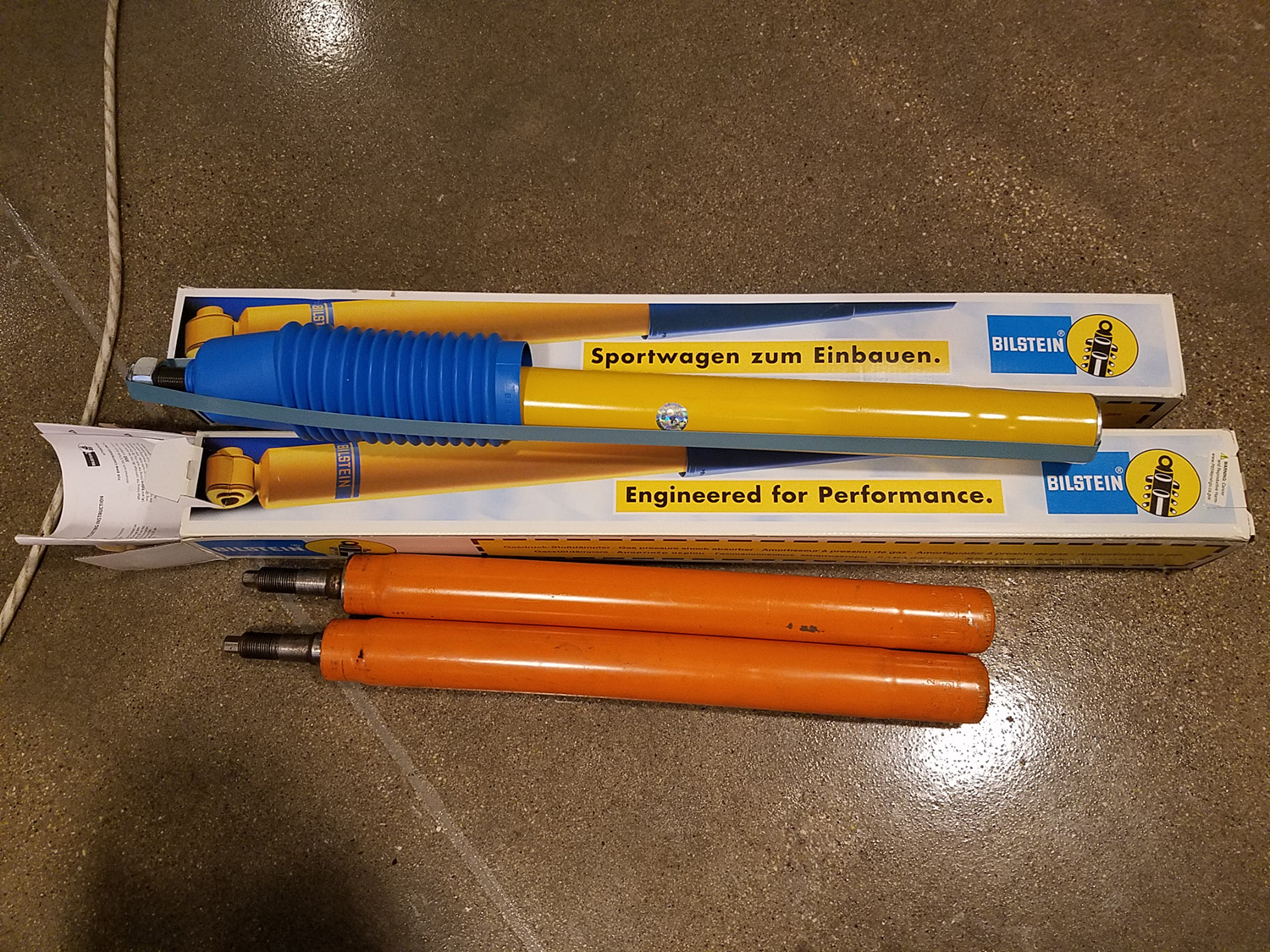

The front strut inserts arrived in record time. Thanks to @bavbob for the recommendation. New ones and the old orange BOGE below.

Here's a question: What is the consensus on replacing the front strut thrust bearing assemblies? The grease in mine is disgusting, and they don't feel smooth (a bit gritty). But these don't see much rotation or heat. I'd planned on cleaning out the bearings, re-packing and re-using. But the rubber that surrounds the housing is torn, I see corrosion below. No bueno. Problem is, these things run $300 each!!! That seems steep. I welcome thoughts and suggestions.

Here's a question: What is the consensus on replacing the front strut thrust bearing assemblies? The grease in mine is disgusting, and they don't feel smooth (a bit gritty). But these don't see much rotation or heat. I'd planned on cleaning out the bearings, re-packing and re-using. But the rubber that surrounds the housing is torn, I see corrosion below. No bueno. Problem is, these things run $300 each!!! That seems steep. I welcome thoughts and suggestions.

Look for the e12 part number, they were cheaper. Those have had a long and useful life, replace them.

Chris is right. I think the e12 version (which is identical, or was) is like half price. I may have a set that I could probably part with that were on my Bav for a very short period of time...like I don't recall if I actually drove with them or not before switching to adjustable camber plate bearings w/ coil overs.Look for the e12 part number, they were cheaper. Those have had a long and useful life, replace them.

Thank you for the intel. I looked up the E12 part on realoem and it is coming up the exact same. Maybe the prices just went way up. Realoem lists them for $137, but that is not the street price. I then did some reading on other threads and stumbled onto the world of camber plates, which seems like a reasonable inclusion for my build. I am struggling because I don't know "what I need". But at this early stage, it seems some options include:

- new stock BMW guide supports = approximately $600 for the pair

- new stock BMW guide supports plus Carl Nelson fixed camber plates = approximately $700 for the pair(s)

- replace with adjustable camber plates from KMAC or Ground Control = approximately $175 to $350 for both sides depending on brand.

It seems that the aftermarket solution will cost less and provide better control. I also plan to run a strut brace and I don't know if the adjustable units will have a conflict with this. So many questions...

- new stock BMW guide supports = approximately $600 for the pair

- new stock BMW guide supports plus Carl Nelson fixed camber plates = approximately $700 for the pair(s)

- replace with adjustable camber plates from KMAC or Ground Control = approximately $175 to $350 for both sides depending on brand.

It seems that the aftermarket solution will cost less and provide better control. I also plan to run a strut brace and I don't know if the adjustable units will have a conflict with this. So many questions...

Stephen, You can get the strut bearing assemblies for the USA cars with the longer studs and then simply replace the studs for shorter ones, or go ghetto and just cut them. The price for those is about $106 after discounts, vs. ~$300 for the one with short studs.

See my post, #13, here:

e9coupe.com

e9coupe.com

Remember our local dealer will give you a 10% discount if you're BMWCCA and no shipping charge even when coming from Germany. Parts that are in the USA they usually get for me in a couple of days and Germany abut a week (pre_COVID)

See my post, #13, here:

Removing 1" front spring US Federal spacer

Ran across the FAQ thread on removal of the 1" front end spacer which I understand was required meet US Federal bumper height mandate. I like the stock stance of my coupe but have to say dropping the front end a bit would be welcome. The FAQ had a note about lowering the studs once the...

e9coupe.com

e9coupe.com

Remember our local dealer will give you a 10% discount if you're BMWCCA and no shipping charge even when coming from Germany. Parts that are in the USA they usually get for me in a couple of days and Germany abut a week (pre_COVID)

Last edited:

m_thompson

Well-Known Member

When I replaced the front strut thrust bearing assemblies there were two part numbers available. One had long studs ('73 and newer) and one had short studs. The short stud ones were something like 3x the price of the long stud version. I bought the long stud version and spent $6 replacing the studs with shorter ones.

I have the same Boge strut cartridges in my CS, and also have Boge rear shocks.

I have the same Boge strut cartridges in my CS, and also have Boge rear shocks.

Wow, THANK YOU! When I look at realoem it does not give me this US post 73 number. But that was the key to success. I just ordered a pair from FCPEuro for $61 each.Stephen, You can get the strut bearing assemblies for the USA cars with the longer studs and then simply replace the studs for shorter ones, or go ghetto and just cut them. The price for those is about $106 after discounts, vs. ~$300 for the one with short studs.

See my post, #13, here:

Removing 1" front spring US Federal spacer

Ran across the FAQ thread on removal of the 1" front end spacer which I understand was required meet US Federal bumper height mandate. I like the stock stance of my coupe but have to say dropping the front end a bit would be welcome. The FAQ had a note about lowering the studs once the...e9coupe.com

View attachment 115323

Remember our local dealer will give you a 10% discount if you're BMWCCA and no shipping charge even when coming from Germany. Parts that are in the USA they usually get for me in a couple of days and Germany abut a week (pre_COVID)

I like a clean look on the strut bearing, the adjustable ones have too much bling. I do use Carl’s fixed plates as well which you can hardly see.

In the interest of "lowering" a car, I see options for the spring pads that range from 10mm, 15mm, 22.5m. Although it looks like the 3.5mm spring pads can be used on top and bottom, too. Is this alone, or always in conjunction with the thicker pads?

Thank you for the intel. I looked up the E12 part on realoem and it is coming up the exact same. Maybe the prices just went way up. Realoem lists them for $137, but that is not the street price. I then did some reading on other threads and stumbled onto the world of camber plates, which seems like a reasonable inclusion for my build. I am struggling because I don't know "what I need". But at this early stage, it seems some options include:

- new stock BMW guide supports = approximately $600 for the pair

- new stock BMW guide supports plus Carl Nelson fixed camber plates = approximately $700 for the pair(s)

- replace with adjustable camber plates from KMAC or Ground Control = approximately $175 to $350 for both sides depending on brand.

It seems that the aftermarket solution will cost less and provide better control. I also plan to run a strut brace and I don't know if the adjustable units will have a conflict with this. So many questions...

Be careful with adjustable camber plates from Ground Control and other places because when I was doing my car, I realized that those plates are generally designed for a shock insert with a threaded stud shaft and bearing ID that is smaller than the one used in the E9/E3. If you look at an E28, the shock shaft is smaller than the the one in the E9. Not sure if this is still the case, but it was a few years back when I made the switch. What this means is that you cannot use a shock strut insert for an E9, it has to be for an E28 or similar as I recall. The original E9 strut housing still works fine.

Drew

I had the fixed negative camber plates in 2016. I needed to replace the front tires after 9600 miles. Left side was -.5° Right side was 0°

Went with these K-Macs: https://k-mac-camber-kits.com/product/bmw-e3-front-cambercaster-street-191716-1j/

They work with stock or CN springs. Now both sides are -1°, wish the were black instead of orange.

Went with these K-Macs: https://k-mac-camber-kits.com/product/bmw-e3-front-cambercaster-street-191716-1j/

They work with stock or CN springs. Now both sides are -1°, wish the were black instead of orange.

You may have a bent strut.

Hey Drew, Thank you for this input. This is very good advice as these parts all have to coordinate. Since my previous post I was able to find the original guide bearings for a reasonable price and plan to use them. I think that decision negates the "adjustable" options. But I may try the Carl Nelson fixed camber plates which I believe work with the stock guide bearings. And all of this works with the Bilstein B6/HD shocks.

I was struggling with the spring pads. There are so many options that have dimension (10mm, 15mm, 22.5mm) and I wasn't sure if one of these was "required" to make the system work. But I've come to the conclusion (thanks in large part to @deQuincey with his detailed post) that I can simply use the thin 3.5mm spring pads on top and bottom (there are actually two different part numbers) and not use any of the thicker spacer pads. Thick spacers are contradictory to the principle of lowering the suspension!

Upper 3.5mm spring pad: 31331100635

Lower 3.5mm spring pad: 31331100636

@adawil2002 I saw your KMACs and they seem like a pretty cost effective option to provide adjustability. At this point I'll try the stock or stock+CN camber plates and see where the car lands. I have to admit, despite the corrosion that I am addressing, the car seems pretty straight (considering its age and mileage). While it is not a Celette bench, the chassis rack I made is holding the car reasonably precisely on the specified chassis points. One day when it's finished, we'll see how the alignment shakes out.

I was struggling with the spring pads. There are so many options that have dimension (10mm, 15mm, 22.5mm) and I wasn't sure if one of these was "required" to make the system work. But I've come to the conclusion (thanks in large part to @deQuincey with his detailed post) that I can simply use the thin 3.5mm spring pads on top and bottom (there are actually two different part numbers) and not use any of the thicker spacer pads. Thick spacers are contradictory to the principle of lowering the suspension!

Upper 3.5mm spring pad: 31331100635

Lower 3.5mm spring pad: 31331100636

@adawil2002 I saw your KMACs and they seem like a pretty cost effective option to provide adjustability. At this point I'll try the stock or stock+CN camber plates and see where the car lands. I have to admit, despite the corrosion that I am addressing, the car seems pretty straight (considering its age and mileage). While it is not a Celette bench, the chassis rack I made is holding the car reasonably precisely on the specified chassis points. One day when it's finished, we'll see how the alignment shakes out.

You may have a bent strut.

VSR measured the the car & everything checked out to be correct. So the left/right side difference wasn't noticed until the fixed camber plates were installed.

I have had Carl's neg camber plates for 8 years with no appreciable effect on tire wear

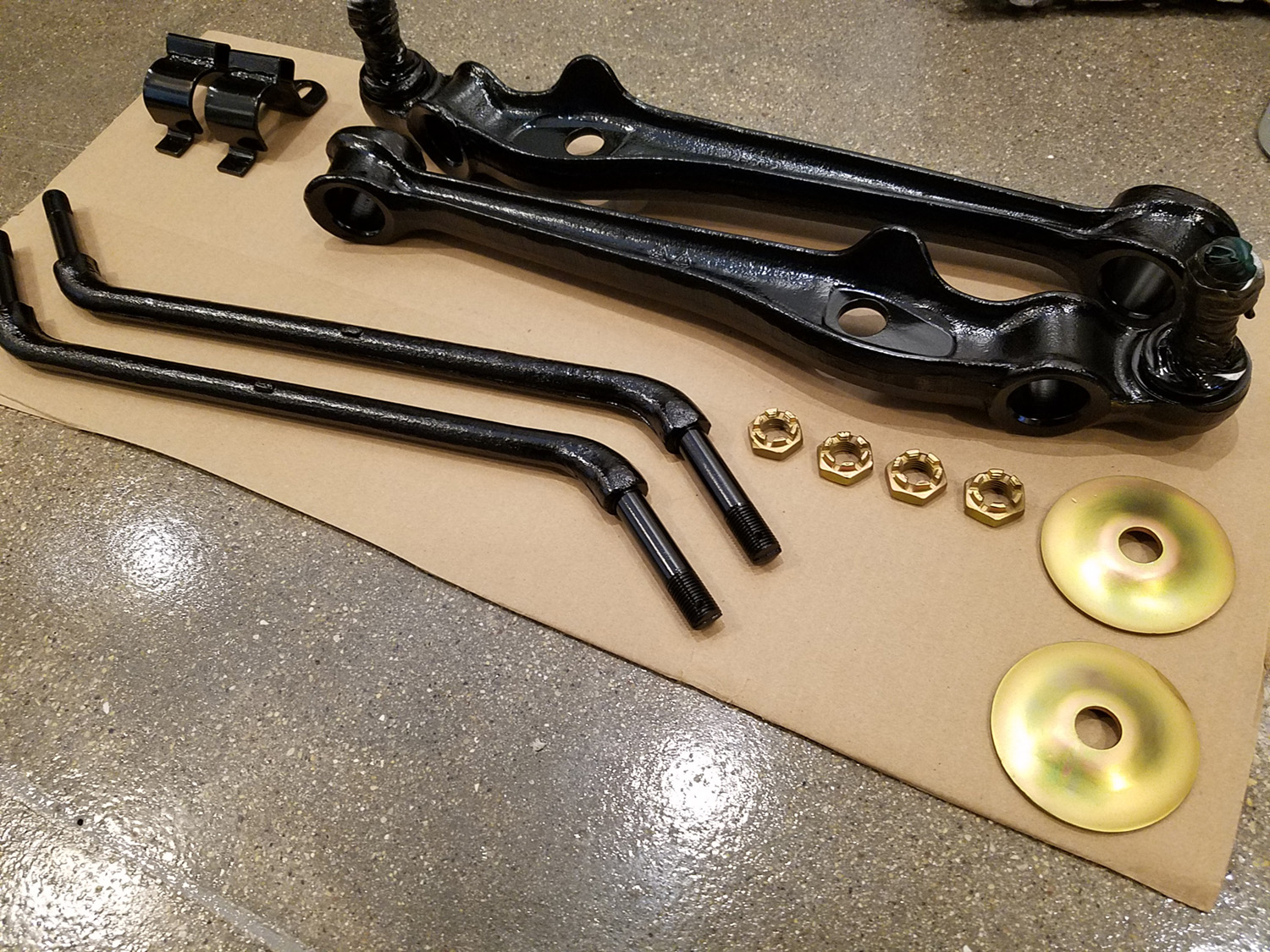

I feel bad that I haven't been posting many photos of finished work. The fact is, I am making "a little" progress in "a lot" of areas. So while things are moving forward, the milestones aren't getting logged in.

Someone once said that restoring an old car is 90% cleaning parts. I think that is accurate. Parts are getting cleaned very well.

And are then painted or plated in preparation for assembly/subassembly.

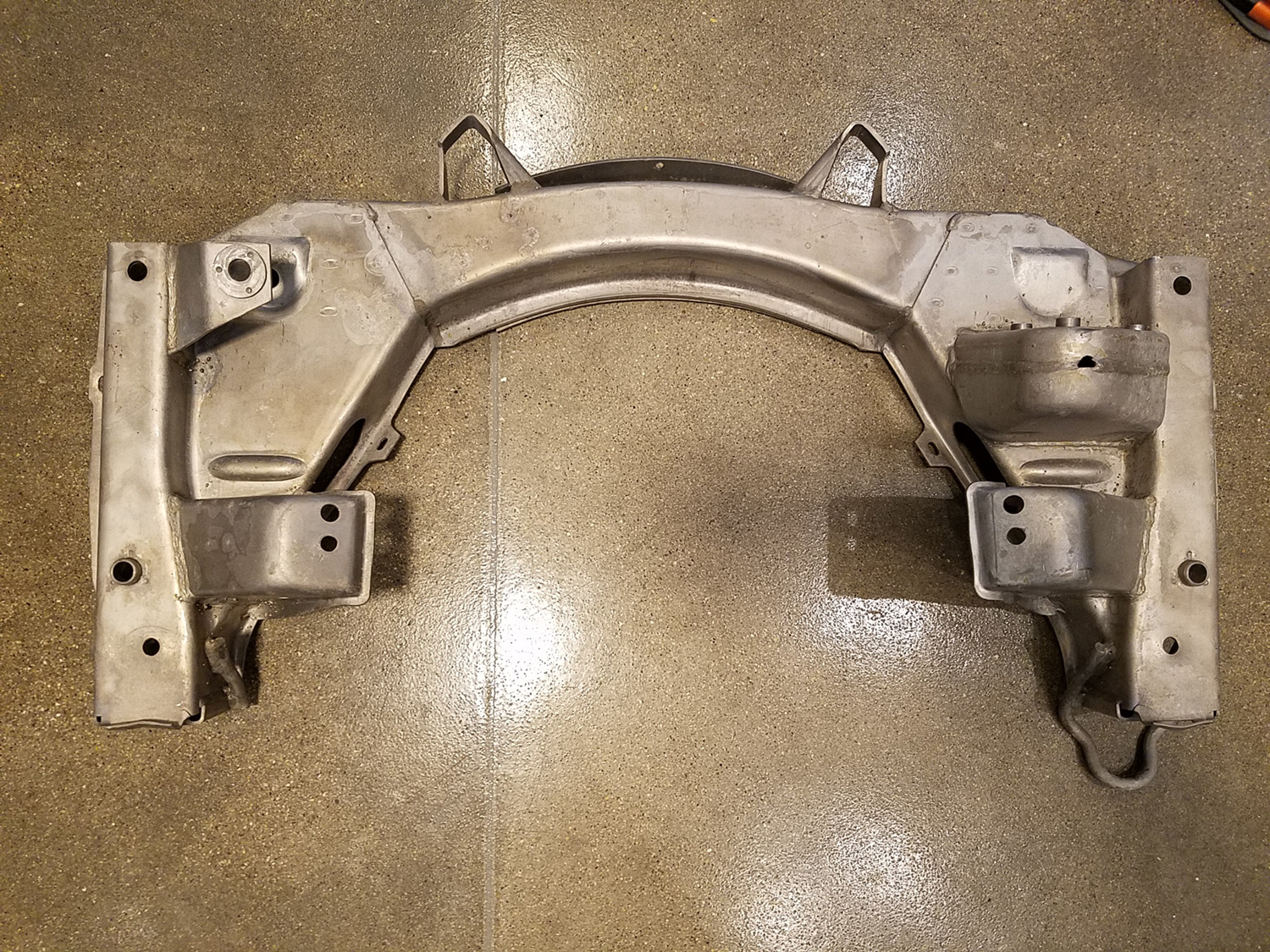

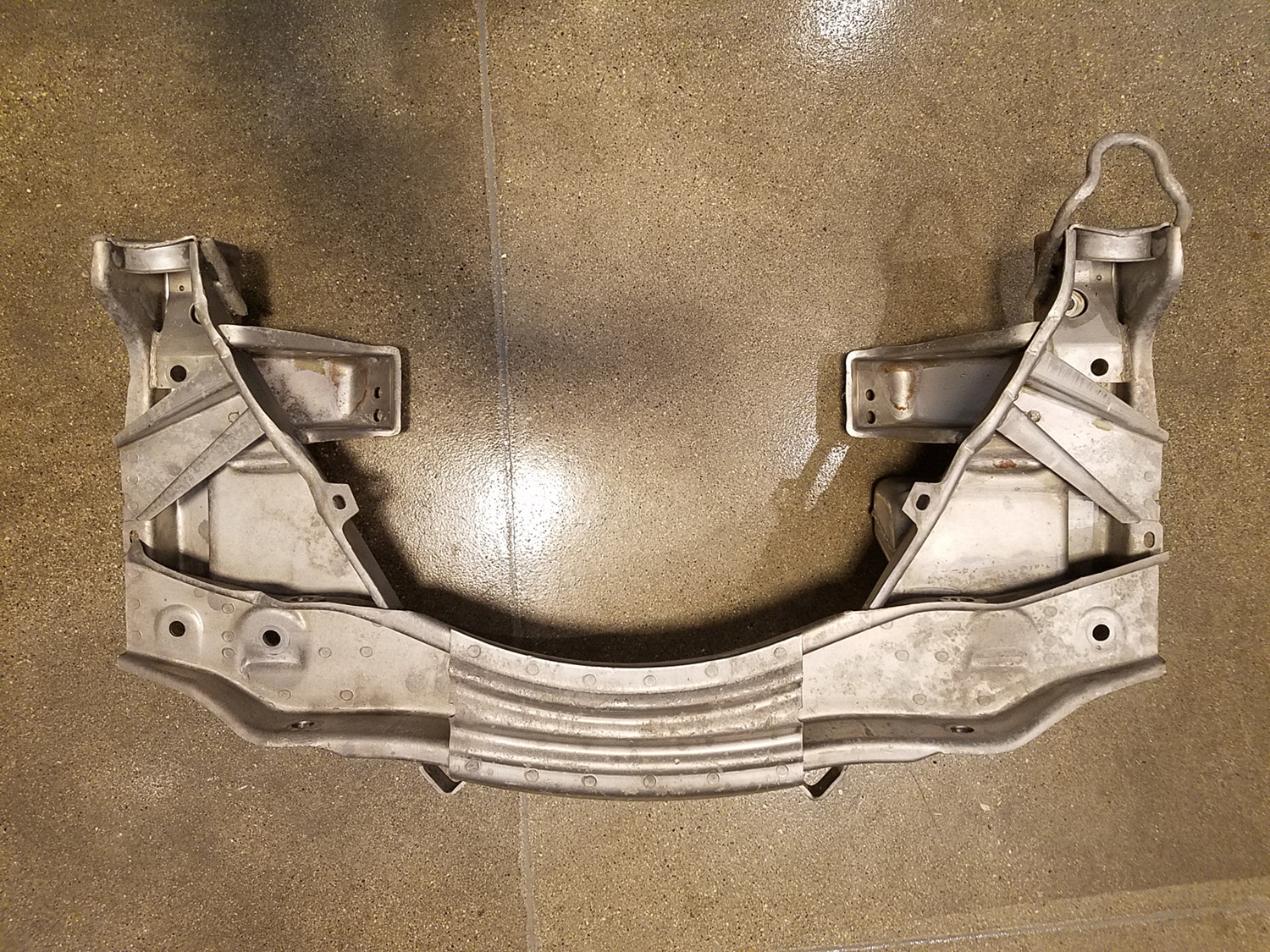

I sent the front subframe out to save time. It needs a lot of little things, and having it clean makes it much easier to assess and address. If you look close, you'll see all of the jack damage from over the years. More on that below.

Some stress cracks from that big, beefy aftermarket sway bar. I recommend that anyone with a beefier sway bar check their subframe in these areas. I plan to weld these cracks up and also add some reinforcement so it hopefully won't happen in the future.

The original BMW welds generally look okay, but I'm not impressed with all of the BB spatter that they left on their parts. While this is not essential, I will spend some time cleaning these areas up.

And look at all of the jack damage on this poor subframe. Clearly some jackass PO and/or their jackass mechanic jacked this car up like a... jackass, for decades.

What took seconds to create took hours to fix. I am about 70% of the way there. Once I am happy with all of the metalwork, I'll do the welding and then prep the subframe for paint.

Someone once said that restoring an old car is 90% cleaning parts. I think that is accurate. Parts are getting cleaned very well.

And are then painted or plated in preparation for assembly/subassembly.

I sent the front subframe out to save time. It needs a lot of little things, and having it clean makes it much easier to assess and address. If you look close, you'll see all of the jack damage from over the years. More on that below.

Some stress cracks from that big, beefy aftermarket sway bar. I recommend that anyone with a beefier sway bar check their subframe in these areas. I plan to weld these cracks up and also add some reinforcement so it hopefully won't happen in the future.

The original BMW welds generally look okay, but I'm not impressed with all of the BB spatter that they left on their parts. While this is not essential, I will spend some time cleaning these areas up.

And look at all of the jack damage on this poor subframe. Clearly some jackass PO and/or their jackass mechanic jacked this car up like a... jackass, for decades.

What took seconds to create took hours to fix. I am about 70% of the way there. Once I am happy with all of the metalwork, I'll do the welding and then prep the subframe for paint.

You are making more progress than you give yourself credit for!

Beautiful work as usual Stephen, You can get the missing tow hook on your front subframe from coupeking before you get it paint it, I think powder coating is the way to go on the subframes, just a little more durable in my opinion.

BTW Do you have a source for the dust cap for the wishbone ball joint? Thanks

Victor

BTW Do you have a source for the dust cap for the wishbone ball joint? Thanks

Victor

Thank you! A couple of weeks ago Erik at Coupe King told me they are out of the tow hooks, but more are coming. I am hoping they arrive soon, else I'll make two new ones (so they match). It would be much easier to buy theirs. Regarding the dust caps, I have a pair coming from Egypt. But we'll see if they actually arrive. I had two other orders cancel because the sellers didn't actually have them. Worst case, I'll use dust seals from a similar Lemforder ball joint.Beautiful work as usual Stephen, You can get the missing tow hook on your front subframe from coupeking before you get it paint it, I think powder coating is the way to go on the subframes, just a little more durable in my opinion.

BTW Do you have a source for the dust cap for the wishbone ball joint? Thanks

Victor