Thanks - I shed a fair amount of elbow grease on it.It looks to be in beautiful condition for its age.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Raven e9 project

- Thread starter autokunst

- Start date

-

- Tags

- restoration list

I spent some time dressing the tips on the spot welder. These are listed as consumables on a device like this, and I wonder if I need to get a new pair. But I did get the current tips shaved down (like a big copper pencil) and then flattened the tips parallel and to a dimension of 5/32" per the specs (4mm). Then I did a series of test welds on some cleaned up 22 gauge material.

The tips are sticking to the material every time, and I am getting weld splash. In two instnaces it burned right through and bonded the tips of the welder together. I believe this is all because I am concentrating too much heat/current. I don't know if it will get better with thicker material (the car will be minimum 20 gauge material). Or if I need to dial this machine's output down in some manner. If anyone has experience with these types of resistance welders, I'd love to learn from your experience.

The tips are sticking to the material every time, and I am getting weld splash. In two instnaces it burned right through and bonded the tips of the welder together. I believe this is all because I am concentrating too much heat/current. I don't know if it will get better with thicker material (the car will be minimum 20 gauge material). Or if I need to dial this machine's output down in some manner. If anyone has experience with these types of resistance welders, I'd love to learn from your experience.

I've used one of those back in the 13th century when I lived in Milwaukee. It was mounted in a floor stand and you used your foot to operate it, freeing up both hands to hold the work.

I would contact the manufacturer and see if they can help; perhaps they offered a more upscale version of that unit with some form of variable resistance alternative. Forms from that era might be a switch with high/low positions or a dial type rheostat.

I would contact the manufacturer and see if they can help; perhaps they offered a more upscale version of that unit with some form of variable resistance alternative. Forms from that era might be a switch with high/low positions or a dial type rheostat.

m_thompson

Well-Known Member

I bought a new one from Grainger in 1982 to reassemble my CS. The existing tips would not fit into many places that I needed to weld. I bought some extra tips and ground them with an offset center so I could make spot welds on the tops of the fenders, and in other tight places.

The same 2.5KVA power rating?I bought a new one from Grainger in 1982 to reassemble my CS. The existing tips would not fit into many places that I needed to weld. I bought some extra tips and ground them with an offset center so I could make spot welds on the tops of the fenders, and in other tight places.

Hey Stephen - There is a forum specifically for Miller spot welders: https://forum.millerwelds.com/forum...older-miller-lectro-spot-model-11-spot-welder

Yep. Have been to that thread and learned a bit about my machine from it. I am still concerned that the Model 33 unit I have has too much horsepower for the sheet metal. I found a chart that describes the proper time duration for the panels. It comes out to 8 cycles per weld. I don't think the 63 year old vacuum tube timer and pretty worn relay contacts that I tried to burnish, but..., has enough precision to repeat the 130 millisecond on time reliably. We'll see.Hey Stephen - There is a forum specifically for Miller spot welders: https://forum.millerwelds.com/forum...older-miller-lectro-spot-model-11-spot-welder

Worst case, I sell the unit I just refurbished and source a more tame version. But I have some new tips coming, and I'll try it out with some more correct sheet metal first.

Walloth Nesch

I know some have stated that they've had trouble with W&N orders - either problems with delivery time or problems with the cost. I just wanted to report that I have not experienced that personally. I ordered some more sheet metal six days ago and it just arrived today. I'd used a 20 EUR discount coupon, so if you apply that to the shipping, I feel these parts made it from Germany to my door step delightfully swiftly. Thumbs up!

I know some have stated that they've had trouble with W&N orders - either problems with delivery time or problems with the cost. I just wanted to report that I have not experienced that personally. I ordered some more sheet metal six days ago and it just arrived today. I'd used a 20 EUR discount coupon, so if you apply that to the shipping, I feel these parts made it from Germany to my door step delightfully swiftly. Thumbs up!

Might be worth trying some shorter copper arms. With my 50cm arms on my spot welder there is a noticeable drop in quality in welds and its easier to punch through. On the thinner stuff I've noticed it really doesn't have to stay on for long to get a solid spot weld

m_thompson

Well-Known Member

The same 2.5KVA power rating?

The one that I have is a Dayton 2Z543 which should be a Miller MSW 41. Mine is wired for 115VAC so it is a 1.5kVA.

Maybe less power is easier for the thin sheet metal?

I believe that to be true.Maybe less power is easier for the thin sheet metal?

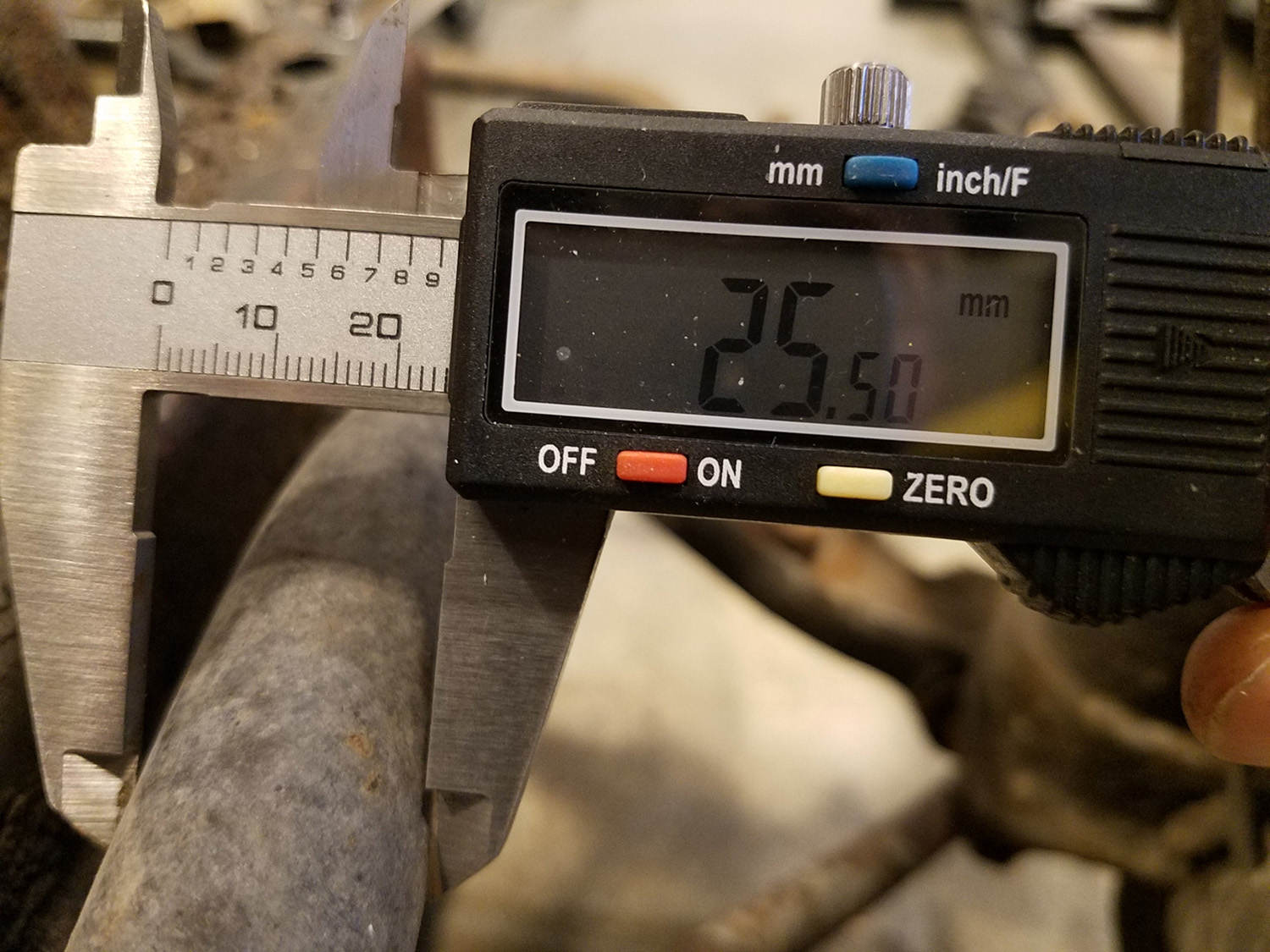

I'm taking a break from the chassis (already) and have started to break down the front subframe. If I recall, the original sway bar was 17mm. The one that was on my car is 25.5mm. That seems to be a more common size on some newer BMWs. I'm wondering if anyone might know what this could have come from? The one from IE is 28.5mm, but looks very similar in shape/profile. And the big question, where does one find bushings to mount a 25.5mm bar with the original bushing straps/housings?

74 was 22mm and you can find those bushings and straps but on yours I have no clue.

The Suspension Techniques I bought from La Jolla Independent are 28mm front, 22mm rear.

RogersTii has 25mm Poly Bushings & new subframe clamps. '02 & E9 use the same clamp.

www.rogerstii.com

www.rogerstii.com

RogersTii has 25mm Poly Bushings & new subframe clamps. '02 & E9 use the same clamp.

rogerstii - Search Results for "swa"

Wrt the spotwelder; when you burn through it is indeed putting to much power in for the thickness of the sheet.

The metal melts into liquid and gets blown away by exploding foreign bits (rust, paint, whatever). With less power, the metal turns more plastic (like dough) instead of watery.

Or, with thicker metal (try 2+2 mm) you'll likely get a decent weld.

The higher the power, the higher the price of these things. Most cheap ~200Usd spotwelded of ebay are not powerful enough to weld 2x 1.5 mm steel sheets of the sill together, let alone the 3 layers you find on an e9.

So having this one isn't bad, as long as you can dial it back. Then it is just a trick of settings.

Most serious hobby equipment nowadays allow to tune both power and pulses/duration.

The metal melts into liquid and gets blown away by exploding foreign bits (rust, paint, whatever). With less power, the metal turns more plastic (like dough) instead of watery.

Or, with thicker metal (try 2+2 mm) you'll likely get a decent weld.

The higher the power, the higher the price of these things. Most cheap ~200Usd spotwelded of ebay are not powerful enough to weld 2x 1.5 mm steel sheets of the sill together, let alone the 3 layers you find on an e9.

So having this one isn't bad, as long as you can dial it back. Then it is just a trick of settings.

Most serious hobby equipment nowadays allow to tune both power and pulses/duration.

Last edited:

I was honestly just going to drill holes and rosette (plug) weld the panels on my car. I latched onto to the idea of a spot welder knowing that @autokunst and @eriknetherlands went that route. I don’t want to put $1K into a spot welder that could go towards a better TIG however. Looking forward to see how you proceed @autokunst.

Me too!Looking forward to see how you proceed

Well, hear in mind that with ons of those cheaper things, you dont have enough power range to weld sills, sure it is gentle enough for thin gauge, but without it you are left with thin sheet capability only.Or I might just sell the mambo unit to someone that needs that power and get one unit that handles my needs better. I had no intention of "flipping" it, but now that I have refurbished it inside and out, I imagine I can get my investment out of it (ignoring my time as always).

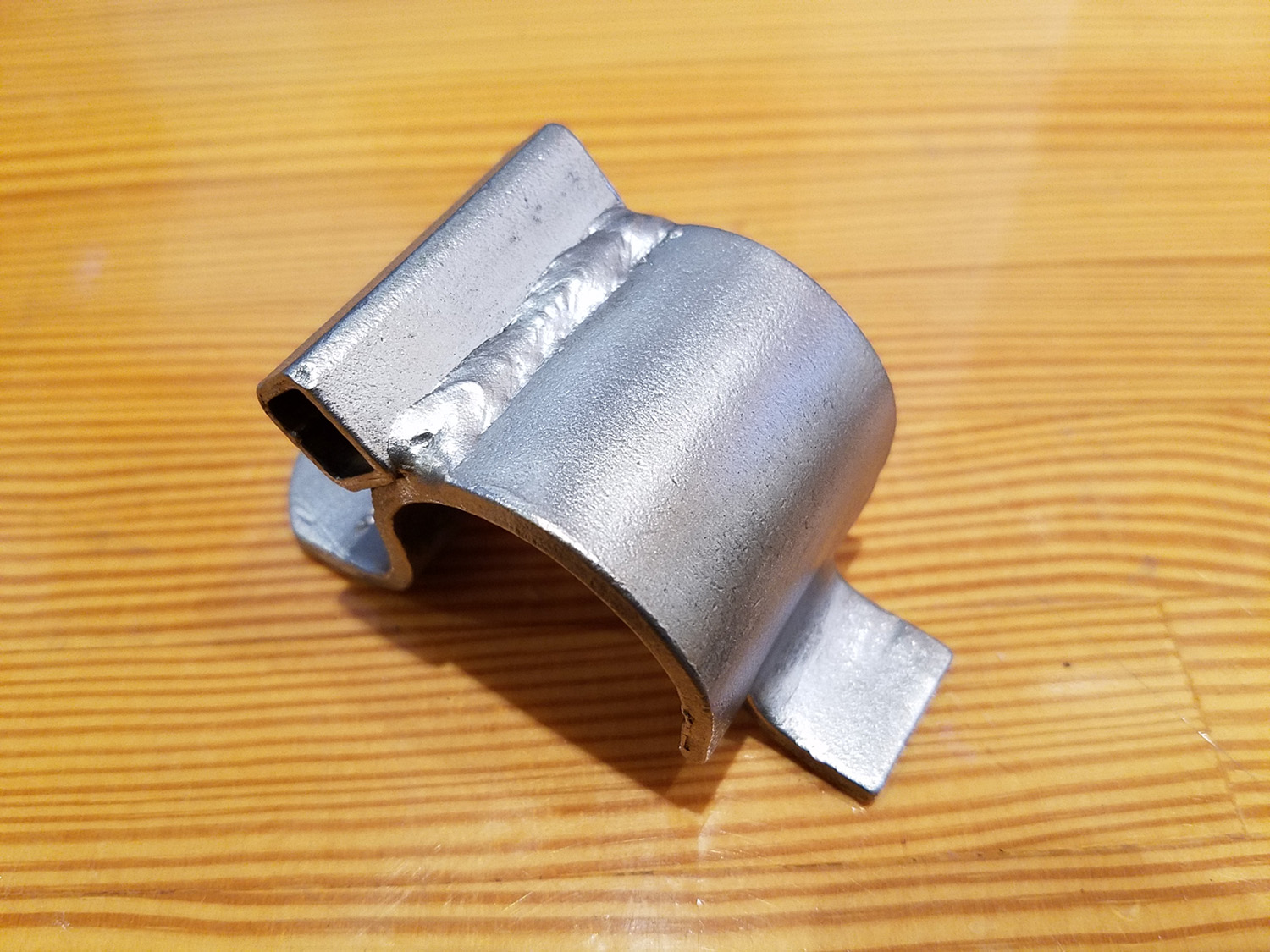

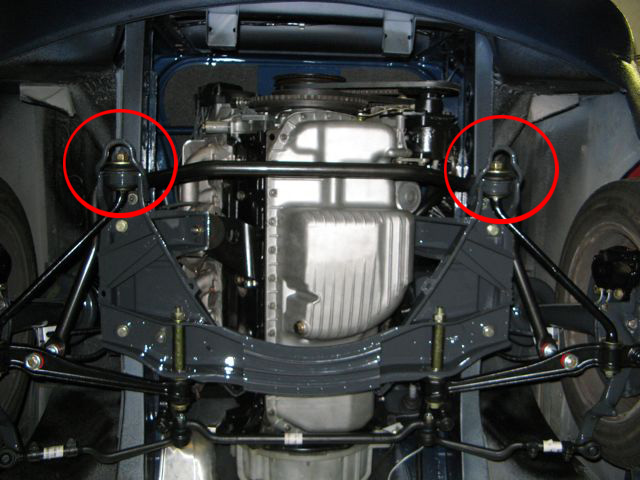

I'm making good progress on the front subframe. While cleaning and refurbishing the bits and pieces, I am reminded of the joy of archeology (or "carcheology") I am having with this car. I've noted previously that I don't really know any of the history of my car. It was a (the best) site unseen purchase, and I learn something new about it nearly every time I'm out in the garage working on it. But I must reiterate my fascination that some previous owner really loved this car and poured a heap of money on what I consider tasteful upgrades to it. There's the Momo Prototipo steering wheel. The higher compression piano top pistons. The Stahl long tube headers. The Hella TN6 driving lights. The list goes on. Earlier I posted that the sway bars are beefier. The front is 25 or 25.5mm bar (depending on if you measure the paint or the raw bar). And today I took special note of the front sway bar bushing brackets - they have been upgraded, too. I'd thought that a skilled mechanic simply made these for the previous owner and was going to comment on how good the welds look. But I have seen these before. I'm not sure what company sold these, but I suspect they came with the sway bar as a kit from one of the well known outfits (Ireland Engineering?). I am delighted to restore them and continue their use on the car.

I am cleaning up all of the front subframe and suspension bits and pieces, getting ready for some platings and/or coatings. I am flush with Verbus, Kamax, and Dera bolts!

Does anyone know what the original/correct finish is for the six bolts (3 per side) that attach the steering arms to the strut tube assemblies? I think I saw NOS ones that appeared to have a black oxide finish, but that seems odd to me.

Also, looking for opinions/feedback on what finish to use on the two large cupped washers that cap off the tension rod bushings. I believe the originals are black, but the ones that some aftermarket sellers are offering are yellow chromate plated. I am trying to be very sensitive to not ending up with "too much" yellow plating, but some is good/correct. I borrowed some photos - and apologize in advance if these are yours.

Does anyone know what the original/correct finish is for the six bolts (3 per side) that attach the steering arms to the strut tube assemblies? I think I saw NOS ones that appeared to have a black oxide finish, but that seems odd to me.

Also, looking for opinions/feedback on what finish to use on the two large cupped washers that cap off the tension rod bushings. I believe the originals are black, but the ones that some aftermarket sellers are offering are yellow chromate plated. I am trying to be very sensitive to not ending up with "too much" yellow plating, but some is good/correct. I borrowed some photos - and apologize in advance if these are yours.