From the bmwcse.com blog:

Shifting Gears

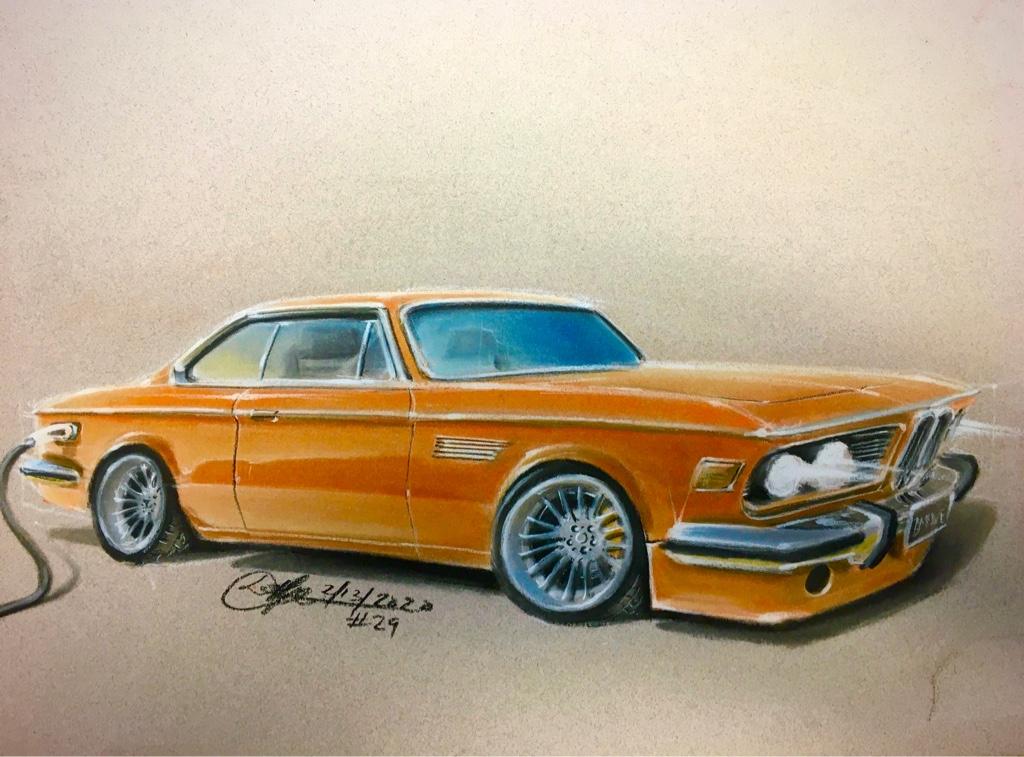

Now that the car runs on Tesla power, there is no need for a traditional gear shifter. Like most modern electric cars (and many gas cars), a simple set of push buttons or a dial would do the job. From the start, however, one of the things that we wanted to preserve about the car was its classic feel. Not just for the looks of seeing a gear shift, but the engaging driving experience it provides. We felt that a classic car required a classic gear selector.

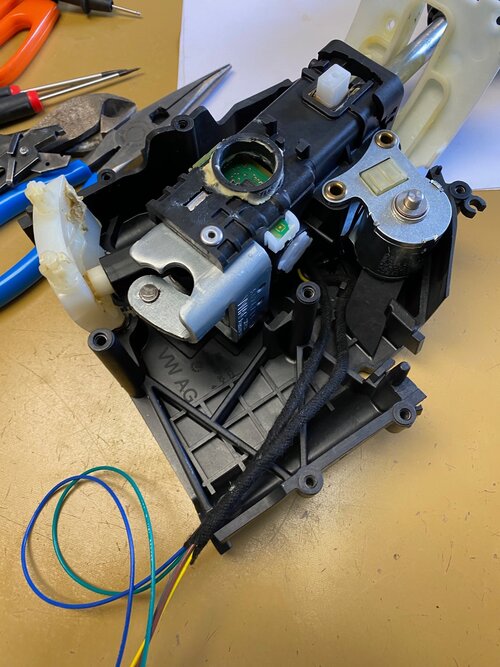

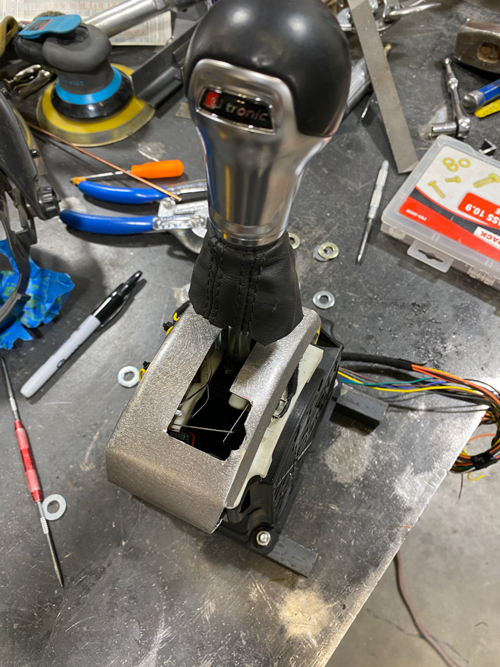

I explored many options for our shifter, starting with those from BMW. In the end I landed on using an Audi TT unit (pictured here). This unit has both an a on-board computer and a mechanical rod which extends to manually put the Audi transmission into its gears. Being a modern shifter, there is also an electric solenoid implemented which locks the shifter in Park for safety unless the brake is pressed, and ignition is on.

Functionality

The gear selector will function like any modern car. There is a button on the grip to release it from Park, so long as the brake is pressed. You will pull back for Reverse, then Neutral then Drive.

Our Tesla drive unit does not have a Park function, which holds the car still when in Park. You might remember a couple of posts back I detailed our use of Brembo/Tesla electric parking brakes. These brakes hold the car from rolling down the street. They are designed for this job, and remain locked even if power is lost or disconnected. For this reason, when our shifter is put into Park, the parking brakes will automatically set. When shifted out of park they will disengage. This is not merely for convenience. Since so few people set their parking brake, I needed to be sure that anyone else who drives my car will not watch it roll down the street after they get out.

Finally, our car has

far more power than we can safely use for everyday driving. I plan to limit the power to perhaps 70% for normal Drive mode. From there, you will be able to push the shifter to the right (the Audi sport/manual shift mode). This will unlock the full power for sport driving, similar to Ludicrous mode on a Tesla. Slide it back into Drive position and the motor will again be reduced to normal, limited power. (There will also be a password-protected Valet mode which

drastically limits the power to 15%).

The Dr. Frankenstein Method

The Audi shifter is both mechanical and computer in operation. It outputs a cable that extends under the car to the transmission which mechanically puts the transmission into the various gears. But there is also an on-board computer which senses the position of the shifter and tells the main computer what gear the car is in, as well as handling the sport mode commands.

For our modern Tesla setup, it makes the most sense to use that on-board computer. I plan to do just that in the final iteration. We will decode the Audi messages then build a simple hardware computer to convert those messages to those our Tesla controller understands. But to get this car out of the shop and onto the road I am going a much simpler route:

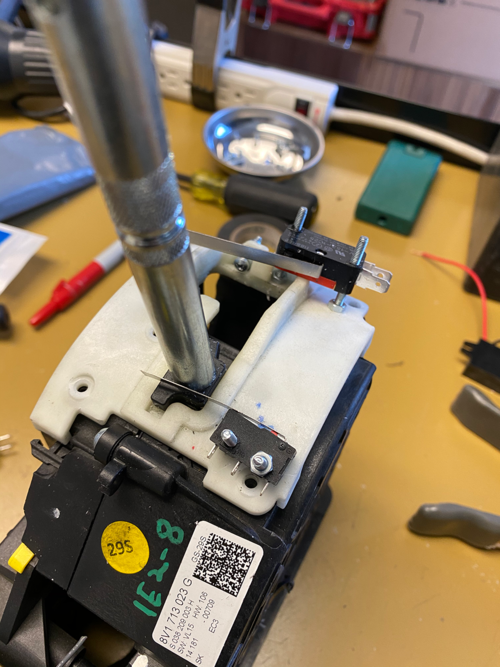

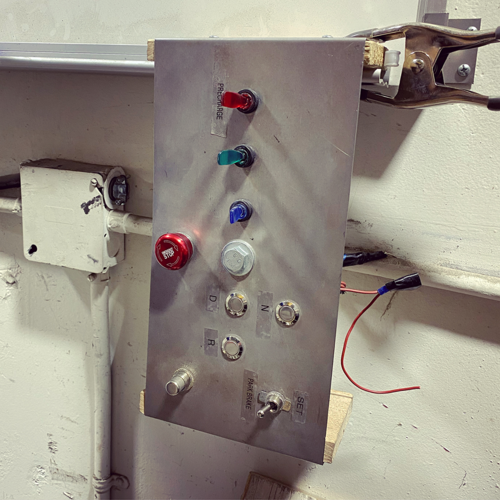

Our Tesla controller uses 12 volt triggers to enable each gear. Remember our spaceship looking control panel from previous posts? Push buttons send 12 volts to inputs on our controller to put the car in gear. I am going to add microswitches to the lever itself. Audi uses a microswitch inside the shifter to tell the computer that the release button has been pressed. So I don’t think I am crazy to add a few more of those little switches for the remaining functions.

I soldered new leads to the solenoid and the release button microswitch. Automotive wire wrap was then used to keep things clean.

Here are our first two microswitches going into place. In this photo the unit is in Park position.

The shifter is all wired up and a custom cover is installed to protect the mechanisms.

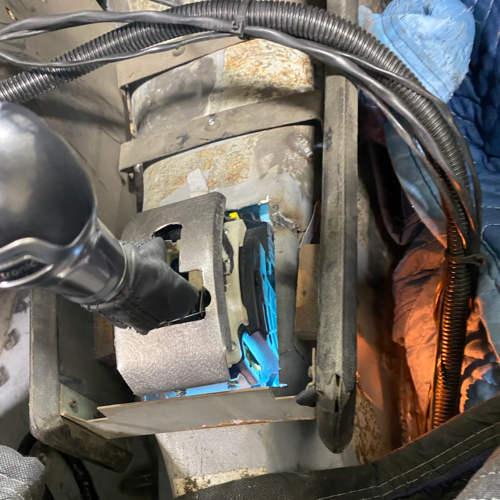

With the shifter held in place Tyler gets busy welding the mounting brackets below. The unit is easily removable for service.

The shifter looks right at home in the console. We will fit a proper leather boot and even fabricate a wooden shift knob when we get to the interior finish of the car.

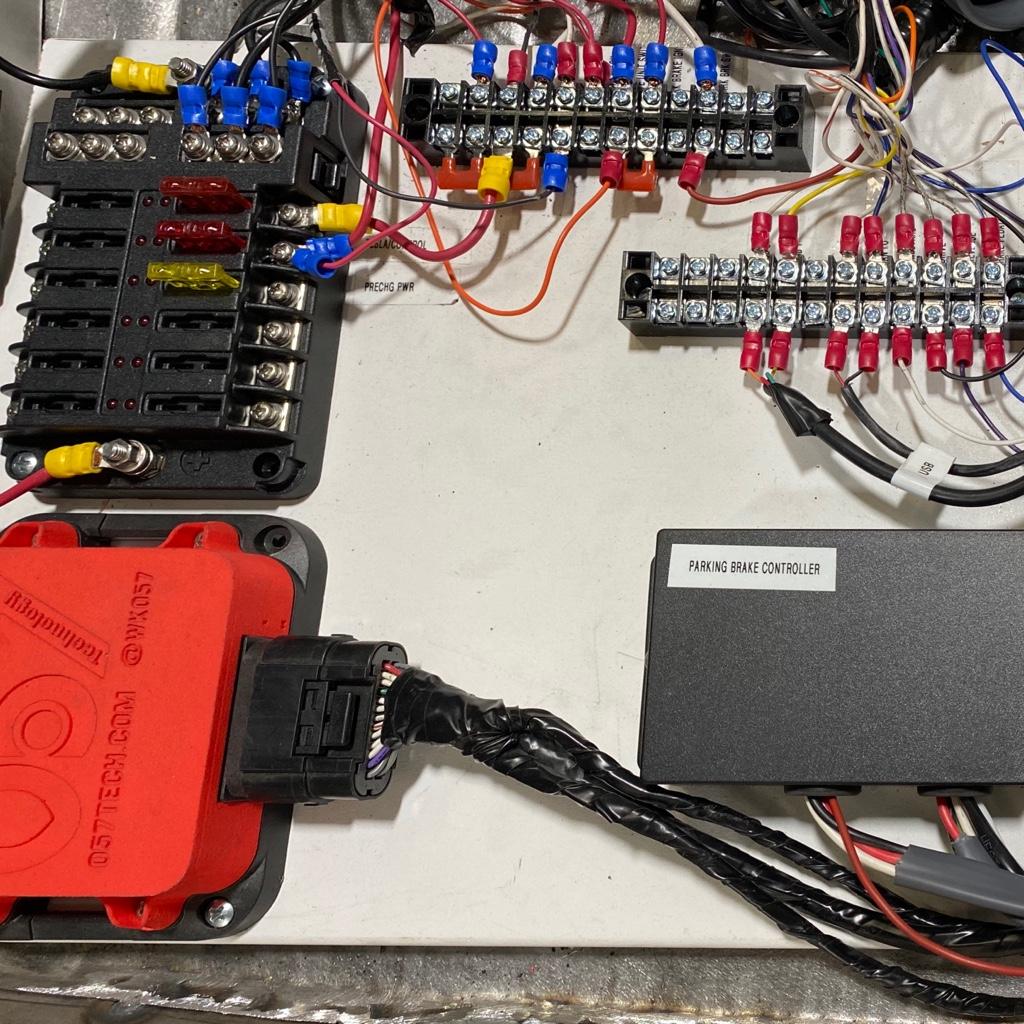

This marks the end of our temporary “space ship” control panel. We’ve now automated every switch and button required to operate the car without it, but we’ll certainly hang onto her as a shop decoration.

After all the wiring, welding and connecting, she looks fantastic and functions wonderfully. The finishing touches will be to properly fit the leather boot and to fabricate a traditional looking wood shift knob. The latter will require some doing, but should be worth the effort. I leave you today with a short little video of our first drive with the shifter installed:

Cheers,

Paul

Cheers,

Paul