Another good week of progress for the CSE! It is officially coming home next Thursday! Well, that is if our drives and testing continue to go well. Here's what I got done this week:

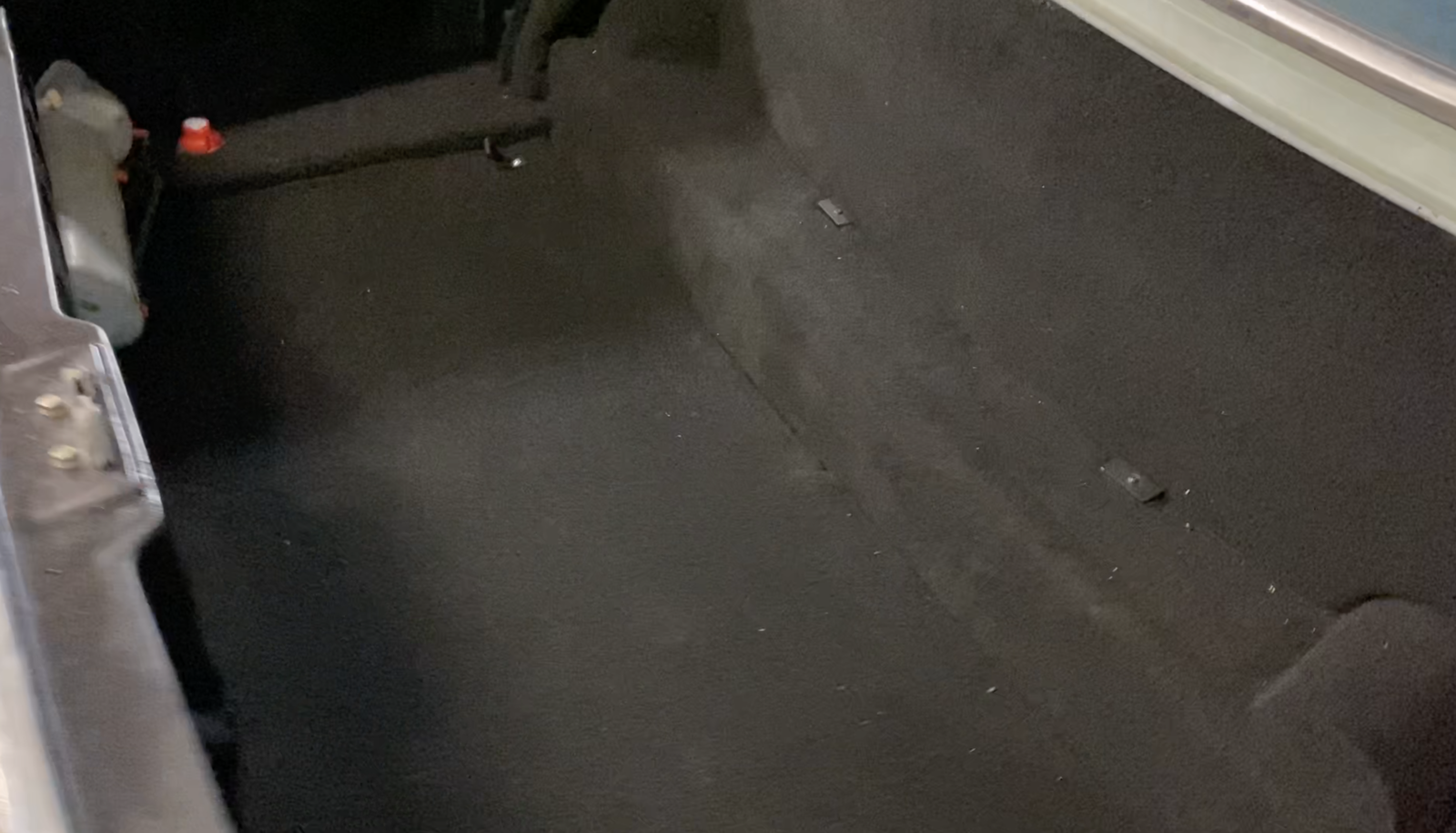

First, Brett handled the carpeting in the trunk. He shaped a piece of plywood to hide the Tesla battery modules on the upper shelf. Then he carpeted the whole place. I know it's not original, but it creates a nice clean and very usable trunk for this daily driver. Notice the tabs for lifting the lower section for access to the wiring and such below (no spare tire here). The 12V disconnect is peeking through as well.

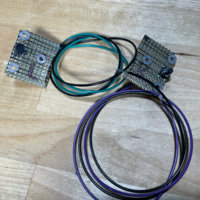

Tyler went back to his crafting table and whipped up this beautiful box for our charging port.

We then painted it to give it the stealth look...

...And the car took its first charge through the proper connector. Up until now I had a MacGyver setup for charging which was safe but ugly.

I went back to work on the console. I cut a piece of mahogany for our stereo. Since our computers are on the shelf behind I had to design a bit of a hybrid approach to the console where I don't use the non-AC parcel shelf running under the stereo. I have a small "phone tray" section which covers the wiring between the shifter and the computers.

I then cut in the Blaupunkt unit. This wood is not yet fully stained in this shot.

The real point of this shot was to show the CSE emblem on the shifter. I am especially proud of this. I measured the Audi Sport emblem and had a company print an epoxy raised sticker on foil with my logo, to my shape. It isn't perfect but it is much better than looking at the Audi logo.

Then Tyler and I pulled the cracked old windshield out and swapped for my new (though not final) clean glass.

The dash got put back together and things are looking very suitable inside. I did get my horn connected.

Now that the car was all back together it was time to take her for a drive. It had been six weeks or more since my last drive. She'd been so "couped" up that she really wanted to run free.

Apparently I couldn't contain my enthusiasm.

I took a couple of photos before putting her away for the weekend. Notice I am halfway done swapping the headlights out for Hella Halogens. I wasn't going to bother and I liked the old lights. But a connector was broken on one of the low beams so I had to replace it with something, so I went this route.

I'm still on the fence about my 17" wheels. I love the grip with all the power i've got, but I keep watching listings for 16" sets and will probably pick some up at some point to at least try them on the car before settling one way or the other.

So it's been a great week. Next week is just a few last things on my list. I've got to get an alignment as the front end is completely custom and we just set it where it looks pretty straight I've got to do a bit more moulding work. I'm going to wire up the sunroof, get my windshield wipers on and such. Every day next week I will drive it further and further with a follow-car so that I can get back to the amount of comfort I had with its reliability before ripping out all the temporary wiring these last several weeks.

I've got to do a bit more moulding work. I'm going to wire up the sunroof, get my windshield wipers on and such. Every day next week I will drive it further and further with a follow-car so that I can get back to the amount of comfort I had with its reliability before ripping out all the temporary wiring these last several weeks.

Cheers!

Paul

First, Brett handled the carpeting in the trunk. He shaped a piece of plywood to hide the Tesla battery modules on the upper shelf. Then he carpeted the whole place. I know it's not original, but it creates a nice clean and very usable trunk for this daily driver. Notice the tabs for lifting the lower section for access to the wiring and such below (no spare tire here). The 12V disconnect is peeking through as well.

Tyler went back to his crafting table and whipped up this beautiful box for our charging port.

We then painted it to give it the stealth look...

...And the car took its first charge through the proper connector. Up until now I had a MacGyver setup for charging which was safe but ugly.

I went back to work on the console. I cut a piece of mahogany for our stereo. Since our computers are on the shelf behind I had to design a bit of a hybrid approach to the console where I don't use the non-AC parcel shelf running under the stereo. I have a small "phone tray" section which covers the wiring between the shifter and the computers.

I then cut in the Blaupunkt unit. This wood is not yet fully stained in this shot.

The real point of this shot was to show the CSE emblem on the shifter. I am especially proud of this. I measured the Audi Sport emblem and had a company print an epoxy raised sticker on foil with my logo, to my shape. It isn't perfect but it is much better than looking at the Audi logo.

Then Tyler and I pulled the cracked old windshield out and swapped for my new (though not final) clean glass.

The dash got put back together and things are looking very suitable inside. I did get my horn connected.

Now that the car was all back together it was time to take her for a drive. It had been six weeks or more since my last drive. She'd been so "couped" up that she really wanted to run free.

Apparently I couldn't contain my enthusiasm.

I took a couple of photos before putting her away for the weekend. Notice I am halfway done swapping the headlights out for Hella Halogens. I wasn't going to bother and I liked the old lights. But a connector was broken on one of the low beams so I had to replace it with something, so I went this route.

I'm still on the fence about my 17" wheels. I love the grip with all the power i've got, but I keep watching listings for 16" sets and will probably pick some up at some point to at least try them on the car before settling one way or the other.

So it's been a great week. Next week is just a few last things on my list. I've got to get an alignment as the front end is completely custom and we just set it where it looks pretty straight

Cheers!

Paul