I might just think about adding that Stephen!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1974 BMW CSE

- Thread starter JetDexter

- Start date

-

- Tags

- restoration list

Wicked cool

Discovered that one of the very costly new fenders had been damaged and repaired. Could have been years ago in Poland, or could have been months ago in Pomona. I asked Ben at CSI about it and he didn’t really give me an answer, so they may have dropped it and repaired it.

It wasn’t a big deal but it cost us a day. The driver’s front lower headlight area. It was repaired old-school with brass. The arc and edge detail wasn’t even close to matching up to original (whereas the passenger fender is perfect).

Just about done now- but a bit of a hassle.

It wasn’t a big deal but it cost us a day. The driver’s front lower headlight area. It was repaired old-school with brass. The arc and edge detail wasn’t even close to matching up to original (whereas the passenger fender is perfect).

Just about done now- but a bit of a hassle.

Making more progress on suspension. The guys at Ground Control do a fantastic job modifying the factory strut insert into their coilover setup. There’s a nice amount of adjustment to geometry up top as well as ride height and of course the Koni damper adjustment.

Attachments

Last edited:

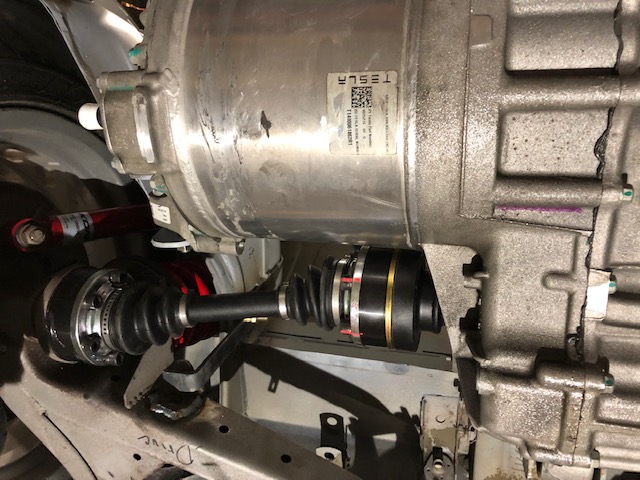

Today we got the Tesla drive unit up and running. Using a sweet race car-style switch board, 320 volts of DC power and a controller from 057 Technologies, we got her running today. Ignore the clicking sound- it's literally the paper plate scraping against the side of the motor

Early next week we get in our Tesla Inner hubs and custom axles that will mate to the BMW outer hubs. We'd be able to drive her around next week if it wasn't for the fact that we have no brakes as yet!

Early next week we get in our Tesla Inner hubs and custom axles that will mate to the BMW outer hubs. We'd be able to drive her around next week if it wasn't for the fact that we have no brakes as yet!

yea nice units can't wait to set mine up also.

Boy it’s been a busy week at work but we’ve still managed to make some nice progress. Driver side fender is welded and looking great. We’ll lead the seams after the rest of the work is done.

We also got the driver’s rockers finished. I opted for custom fabricated outers which will be painted with the car.

We will cut out holes for the lift points, and fabricate caps on sprung hinges. They will hinge down and under the car. The spring will normally hold them closed. We’ll see how those turn out

Lastly, we got our brakes in. Doing a Wilwood big brake setup. They ought to stop her pretty well. Disassembled the calipers to have them powder coated orange. (For the record, I am figuring to paint the car back to her original Polaris rather than the orange of my mock-up, but there will be orange stitching in the leather and the calipers will be orange. That will be my nod to my favorite color, while keeping the car in its original - and probably my favorite - color for these coupes.

We also got the driver’s rockers finished. I opted for custom fabricated outers which will be painted with the car.

We will cut out holes for the lift points, and fabricate caps on sprung hinges. They will hinge down and under the car. The spring will normally hold them closed. We’ll see how those turn out

Lastly, we got our brakes in. Doing a Wilwood big brake setup. They ought to stop her pretty well. Disassembled the calipers to have them powder coated orange. (For the record, I am figuring to paint the car back to her original Polaris rather than the orange of my mock-up, but there will be orange stitching in the leather and the calipers will be orange. That will be my nod to my favorite color, while keeping the car in its original - and probably my favorite - color for these coupes.

Great update. I’m curious if you really are going to use lead. I’ve been thinking about it. I watched a video showcasing Bill Hines the other day. It is informative but also funny to watch. Blow torch waving around by oily rags and paper towels. Loose clothing. No gloves, leather or otherwise. No mask, big cigar.

That is hysterical. Using a blowtorch to relight his cigar...

Oh my goodness that's the greatest thing I have ever seen! I'm excited to see the process- Tyler's done a lot of it, and I will just be ready to jump in with the cigar as needed.

THAT GUYS A PERFECT CARTOON

Our new axles finally arrived. Since the Tesla parts department consists entirely of t-shirts and wheels, you can't buy an inner portion of an axle. So I purchased a pair of axle assemblies, cut the inner boot and pulled the inner, discarding a lot of good parts.

Lee and the folks at The Driveshaft Shop do some amazing work. They machine and weld the inners to a 6 bolt flange which would mate to BMW axles. I also had them make new axles built for the increased torque and horsepower.

And for fun, here's a little video showing a nice milestone. We have spinning wheels.

Lee and the folks at The Driveshaft Shop do some amazing work. They machine and weld the inners to a 6 bolt flange which would mate to BMW axles. I also had them make new axles built for the increased torque and horsepower.

And for fun, here's a little video showing a nice milestone. We have spinning wheels.

So you are saying that you have four parts (motor/single-speed-gearbox/LR axle flanges). This replaced, motor/clutch/gearbox/driveshaft/differential). Batteries replace fuel system, cooling system, and exhaust. Tesla’s aren’t simple machines but there is beauty and simplicity in electrification. I absolutely love it. I was dreaming of owning a DC 914 running on golf cart batteries 20 years ago. I’m happy to see this moving along!

Paul was gracious enough to host a small open house for a few members of the forum today. Thanks, and happy 80th to your Dad, Paul! Shown below (left to right) are:

HB Chris, JetDexter (Paul), BMachine, and JeffLit.

His project is very impressive. I vacillate from overwhelmed to inspired. If only it was as simple as bolting in a motor, attaching axles, and plugging in. He's tackling a whole host of problems, from battery management to capacitor initialization to in-dash display, CAN bus, hydro boost, battery cooling, motor/diff/inverter cooling, shifter, HVAC, battery placement, wiring, etc. He's got a lot going on. But we're witness to the fact that it does indeed have throttle and spins the wheels.

And that ignores all the rust repair that his buddy Taylor (below) has been fixing. Today he was installing new door skins. For most of us, rust repair is the toughest part of the build but for Taylor and Paul it's just one small part.

Thanks again for being generous with your time, Paul.

HB Chris, JetDexter (Paul), BMachine, and JeffLit.

His project is very impressive. I vacillate from overwhelmed to inspired. If only it was as simple as bolting in a motor, attaching axles, and plugging in. He's tackling a whole host of problems, from battery management to capacitor initialization to in-dash display, CAN bus, hydro boost, battery cooling, motor/diff/inverter cooling, shifter, HVAC, battery placement, wiring, etc. He's got a lot going on. But we're witness to the fact that it does indeed have throttle and spins the wheels.

And that ignores all the rust repair that his buddy Taylor (below) has been fixing. Today he was installing new door skins. For most of us, rust repair is the toughest part of the build but for Taylor and Paul it's just one small part.

Thanks again for being generous with your time, Paul.

The local chapter of Tall Guys SoCal, lol. Great visit, I'm so impressed with the vision and execution to pull off a project this daunting in my eyes.

Couldn’t thank Paul enough.

And indeed, good to see the 6’2 / 1,88 and over e9er club alive and well.

And indeed, good to see the 6’2 / 1,88 and over e9er club alive and well.

Thanks guys,

It was really great to meet you guys in person, share BMW stories and show you the project. You are welcome any time.

Come back in a month or two when we have brakes and a battery box and we can take turns circling the complex!

Cheers!

Paul

It was really great to meet you guys in person, share BMW stories and show you the project. You are welcome any time.

Come back in a month or two when we have brakes and a battery box and we can take turns circling the complex!

Cheers!

Paul

So you are saying that you have four parts (motor/single-speed-gearbox/LR axle flanges). This replaced, motor/clutch/gearbox/driveshaft/differential). Batteries replace fuel system, cooling system, and exhaust. Tesla’s aren’t simple machines but there is beauty and simplicity in electrification. I absolutely love it. I was dreaming of owning a DC 914 running on golf cart batteries 20 years ago. I’m happy to see this moving along!

Markos, All true (your comparisons) other than one detail. The batteries do require cooling- there are small in and outs which need to be chained together and sent through a pump and tiny radiator. The Drive unit also has coolant with a small radiator. This is not a huge deal, but does give it one more tick of complexity and plumbing that is a bit unexpected at first glance.

I too had visions of creating a Fiat 124 Spider (which I had at the time to a 12v and Lead Acid battery car in the 90's. A guy near me had done a VW pickup with batteries in the truck bed and I loved it. I waited 20 years to finally jump in.

A '69 2002 that I have in storage that's getting an M20 swap used to be an electric car. There was a small group of engineers I worked with at HP that designed a controller for the power/systems and they needed a test vehicle. They had an old 2002 sitting around so it got picked. Electric motor adapted to the stock trans with batteries in front and back. The decklid even had vents formed into the sheet metal for ventilation. I don't think anything ever came of the controller design.

I was wondering about the batteries. I wonder if I can get more time out of my 20v power tools if I add liquid cooling?

BTW - I’m not trying to over simplify the effort I was really only focusing on moving parts, not the wizardry required to make it all function.

Tyler isn’t old enough and tough enough to be a panel beater. Pics of finger purple finger nails or I am crying “stand in”. Tell him he has a face meant for a Discover channel reality show. Does he have an abrasive personality that would make your new “Electrify” show interesting? Do it!!!

BTW - I’m not trying to over simplify the effort I was really only focusing on moving parts, not the wizardry required to make it all function.

Tyler isn’t old enough and tough enough to be a panel beater. Pics of finger purple finger nails or I am crying “stand in”. Tell him he has a face meant for a Discover channel reality show. Does he have an abrasive personality that would make your new “Electrify” show interesting? Do it!!!