I would also like to mention that

Just want to make it clear, I did not publish anything that was not mine, nor have I published anything at all.

Agreed. The whole thing is a no fault misunderstanding, and none of that had to do with chris anyway.

I would also like to mention that

Just want to make it clear, I did not publish anything that was not mine, nor have I published anything at all.

hey Mark, so what do these cost for you to print a set. i could probably use a set.

scott

When shopping around, make sure you understand the material properties. It would be a shame if people ordered and when they received they warped

Markos, can you print the air plenum that sits behind and between blower and the a/c facia

i would take AEARCH's drawing and have an a/c duct maker with a brake press make one. it wouldn't be that hard

i would take AEARCH's drawing and have an a/c duct maker with a brake press make one. it wouldn't be that hard

i have given this some thought - the easiest place is to put a side e28 grille or two where the dash speaker goes. anywhere else requires surgery. i have also given some thought to connecting the side hoses to the defroster vents to throw conditioned air up.

Hey Marko ,Before selling my AC Setup, I decided to send the E9 face plate out to a SolidWorks modeler to recreate. The part is in the mail and I should have a draft design by the end of next week.

I called for three designs. One with the standard radio opening, one that is blank, and one that has three gauge holes. The blank one may have lines in the back to facilitate the cut out of the radio on the future. I haven't checked if gauges will fit the space yet. My CSI was a rats nest of stereo wires in that area.

I intend to print with a professional 3D printer, and sell them with a markup to

cover the cost of the modeling. A BMW friend of mine runs a PolyJet printer, and has numerous printing contacts in the Seattle area. Technically they could be printed with powdered aluminum, perhaps for the concours crowd.

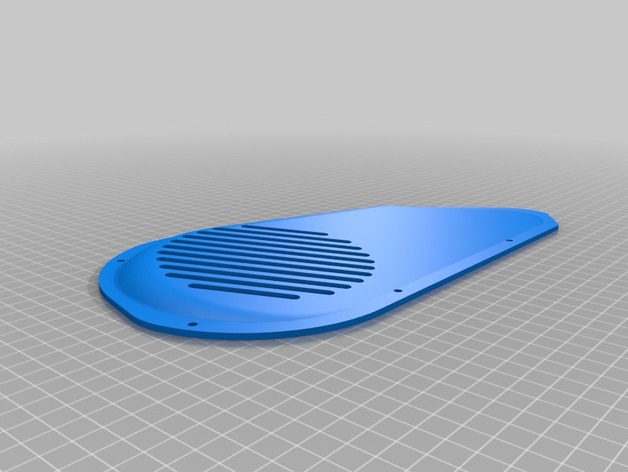

Oh - I also sent the AC grills. I haven't paid for those yet, but I will likely have them modeled also. I would imagine that those are much easier to sell.

Keep you posted!

Hey Marko ,

No luck with finding the chrome D-side hood vent,I contacted the link you sent me but of course they're "not available" . I have a guy in Nashville who can chrome plate plastic. Could you 3D fab. the vent?

Can you get your hands on a black drivers side one ??If you are going to get them chromed, it would be cheaper to start with brand new black vents. 3D printing isn’t cheaper than cast parts that are masses produced (yet).