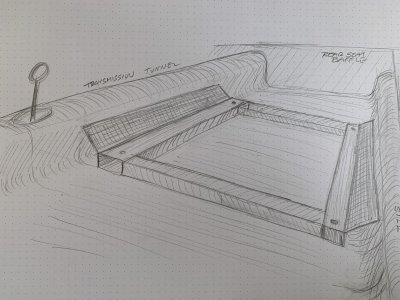

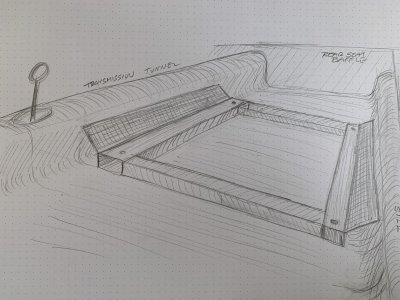

Today was a big day. As I mentioned here and there, I had always wanted a better seat and I really liked the e92 sport seat for their comfort, and adjustable side supports. I especially liked the fact that the 2 door version of the seats were in a style that looked it could have evolved from the original cs seats. Only problem is, they don't work with the original seat brackets at all. I was also very concerned about losing any kind of structural strength by removing the original "bridge" that goes from the tranny tunnel to the side rocker. I did a lot of research and a few people who had installed these seats had to add plates on the underside of the car. I wanted this mod to be as invisible as possible, so with the help of

@eriknetherlands and later

@tygaboy we designed a frame that would sit as low as possible without requiring any visible change under the car.

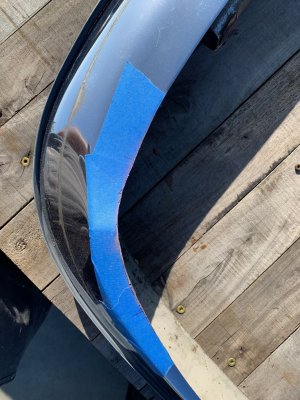

First I removed the original seat brackets. Originally I had tried removing only the center part of the bridge. Later we realized the whole thing would need to come off.

Then I tested the base frame with a wood mock-up.

But it needed better structural support

Finally, today, I drove the car to Chris Baker's and he did his usual welding magic to build the whole frame and the side wings. With that done, we have an incredibly strong base which ties as high as possible to the tranny tunnel and to the side sill (he used the original weld location there) but extends quite a bit further back than the original. I had noticed that, when adjusted for taller drivers, the original seat would hang unsupported in the back because the length of the original seat bracket is so short. This system fixes that problem nicely.

Chris also welded a bracket which ties to the front subframe.

After we reinstalled the seat, we were looking at it and Chris says "Damn, after all that work, we can't even see anything." I didn't tell him at the time because he worked so hard on it but, that was exactly what I had hoped...

The driving experience is significantly improved and the structural rigidity I was so concerned about does not feel like it had been compromised at all.

A million thanks to Chris

@tygaboy for his invaluable help and to Erik

@eriknetherlands for his early engineering help on the design.