I am assuming "VB" means accepting bids?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My vintage VGS air collector box project

- Thread starter Stevehose

- Start date

There is an interesting header further down in the eBay add. Any idea brand?

John

John

I am assuming "VB" means accepting bids?

Basically means the price is up for discussion..

(No affiliation by the way, just sharing some interesting parts!)

Wow. Would need close up pics, it appears that the aluminum box section groove that slots in the airbox is missing a 6 inch piece along the top side. The lower area appears to be only red paint coming off the black underneath. I wonder how much he wants and I'm assuming the manifold is included...maybe the CSi airbox?

Could be somebody’s lucky day:

Gebrauchte Autoteile günstig kaufen | kleinanzeigen.de

Kleinanzeigen: Gebrauchte Autoteile günstig kaufen - Jetzt in Hadern finden oder inserieren! - kleinanzeigen.dewww.ebay-kleinanzeigen.de

Last edited:

@mmccusername

Basically means the price is up for discussion..

(No affiliation by the way, just sharing some interesting parts!)

View attachment 109251View attachment 109252

Further down he states "

I am selling a complete intake system for Weber carburettors. Air filter, air collector and pipe. Very rare!!! If you have questions, just call. Due to the large number of interested parties, I am now putting a fixed price in here. Anyone who knows how rare the parts are. And above all what their value is.

So, he is firm on 850 euro = $1008.00 USD

@Stevehose , what do you think of that price?

I am selling a complete intake system for Weber carburettors. Air filter, air collector and pipe. Very rare!!! If you have questions, just call. Due to the large number of interested parties, I am now putting a fixed price in here. Anyone who knows how rare the parts are. And above all what their value is.

So, he is firm on 850 euro = $1008.00 USD

@Stevehose , what do you think of that price?

Also further down is posted what looks like a perfect set of tail lights with the housing for 950 euro.

I asked him to send or post more photos. Hallo, ich bin am Donnerstag wieder in der Werkstatt. Dann schicke ich Bilder = Hello, I'll be back in the workshop on Thursday. Then I send pictures. If it is the air box, and everything all the way to the manifold $1000 would be a good price, wouldn't it?Wow. Would need close up pics, it appears that the aluminum box section groove that slots in the airbox is missing a 6 inch piece along the top side. The lower area appears to be only red paint coming off the black underneath. I wonder how much he wants and I'm assuming the manifold is included...maybe the CSi airbox?

I also sent a message on the German EBay site to the seller. His reply to me this morning was:

"air filter and air intake manifold not"

The Google translater might have missed any more of his reply. But it sounds like the intake manifold might not be part of what he's selling.

The seller would not have to remove the 3 carbs and go with individual air filters after selling the other items.

And the buyer will not have the complete system and have the airbox hitting the brake booster with any other manifold.

"air filter and air intake manifold not"

The Google translater might have missed any more of his reply. But it sounds like the intake manifold might not be part of what he's selling.

The seller would not have to remove the 3 carbs and go with individual air filters after selling the other items.

And the buyer will not have the complete system and have the airbox hitting the brake booster with any other manifold.

The aluminum housing that attaches to the carbs has a large piece broken off the top section as seen in the pic, I am not sure if this can be repaired since it is aluminum. If it comes with the intake manifold then it might be worth it, but I am not convinced it does. I think he is referring to the red airbox, broken aluminum housing, corrugated hose, and CSi airbox, but as @Drew Gregg noted, now it seems the CSi box is not included. If that's the case, I wouldn't pay 1000 + shipping for the airbox in that condition, certainly without more close up pics.

I asked him to send or post more photos. Hallo, ich bin am Donnerstag wieder in der Werkstatt. Dann schicke ich Bilder = Hello, I'll be back in the workshop on Thursday. Then I send pictures. If it is the air box, and everything all the way to the manifold $1000 would be a good price, wouldn't it?

mmccusername

Well-Known Member

I already have the VGS manifold so this could work for me, but I think the seller has gotten overly excited about an airbox in that condition.

I've completed my piano top piston project to go with the VGS airbox and manifold setup, a little "go" to go with the "show". My engine has a Schrick 284 cam and triple Webers, and until now the crappy USA 8:1 pistons. For years I've wanted to put piano top high compression CSi/L pistons in. First I bought a set that were too big. Then @Wes sold me his standard size from his CSL that he is rebuilding oversize. My engine only has 85k miles and wasn't burning any oil so I decided to replace with standard size.

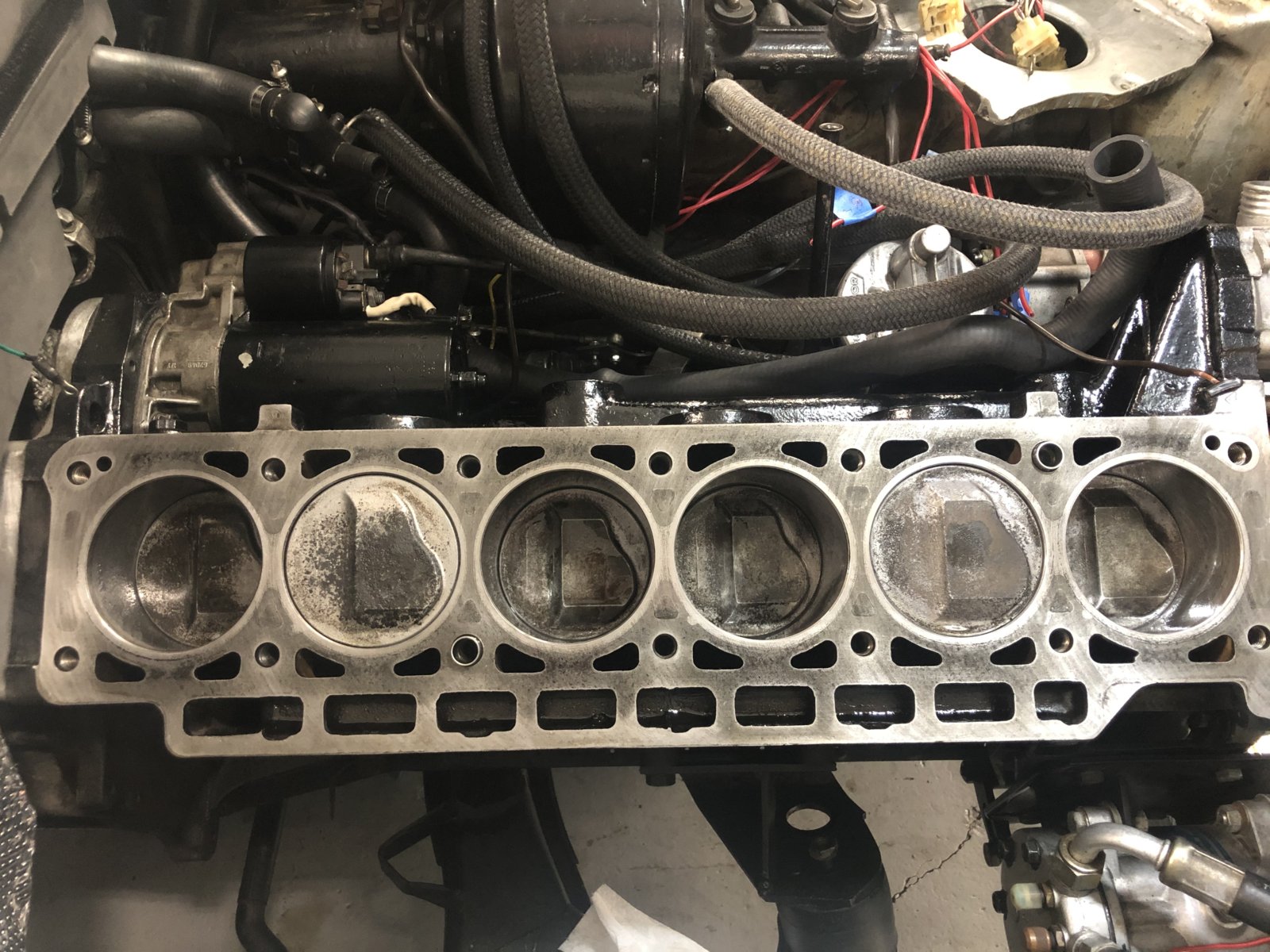

I also didn't want to pull my engine and pay big bucks for the total rebuild on a low mileage engine so I challenged myself to do this engine-in-situ after reading the blue book on how to replace a piston, I thought what the heck I'll do all 6 . Off everything came to get to the pistons, while doing this I took time to refresh many things along the way (a list later). Existing pistons out:

. Off everything came to get to the pistons, while doing this I took time to refresh many things along the way (a list later). Existing pistons out:

I am very glad I did this because one of my pistons was missing a gudgeon circlip (the pin easily slid out from one side) and #6 cylinder rod cap bolts had lost their torque and were not very tight! Yikes. Onward...

@stphers took me under his wing and gave me invaluable advice and encouragement along the way, thanks RIck! He told me how to hone the bores and get the cross-hatch:

And polish the crank with 600 wet sand and a shoelace from below. While the pistons were at the shop getting my connecting rods put on and balanced, I did major detailing and rewiring. I had no less than 7 connections to the + side of the battery for accesories which has bothered me for years, looks like crap all cluttered. Before:

I installed a vintage style fuse box on the firewall (with the same torpedo fuses as under the dash) to fuse the relays of the horn, high & low beams, and window relays/stereo amp. I realized while doing this that not only is the low beam circuit not relayed (I changed that years ago), but neither high or low beams are fused. The horn has a fuse but it's not the relay that is fused. I also cleaned up my driving light circuit and a/c fan relay connections and wiring etc under the headlight acess panel. Here's the fuse box with beefy wiring, it's fed off the starter post and big cable from the battery:

And the result of the rewire is I now just have the original cable to the battery with no janky clutter (hmmm I need to clean up that tape):

Next I measured and filed the piston ring clearances and installed the piano tops, torqued the rod caps (new bearings), clearance is .038mm so in spec:

Put it all back together and spun the engine with no plugs in to get oil pressure. Repeated a couple times. All good. Put the plugs in and she started right up! I did the break in/ring seating procedure for 20 min then drove it 30 miles with various revs/engine braking then changed the oil. Definitively more pep and power.

Once satisfied it was running ok I put everything back together in the engine compartment (this took a week). Here is a list of what was done during this 2+ month project:

Installed euro piano top pistons

New rod bearings, rings, bores honed, crank polished

Retensioned loose oil pump chain with shims (cold start knock now gone)

New head gasket

Sanded and POR-15 repainted exhaust, all new hangers

Painted brake booster (new decal) and blower motor cover plate

Cleaned all engine components and brackets, oil pan, valve cover, etc.

Differential fluid changed

Power steering fluid changed and reservoir cleaned & repainted, new hoses and filter

Tranny cleaned, fluid drained & replaced, new Coupeking bracket (it's a beast) to be installed next

All new radiator and heater hoses and clamps

New brake booster vacuum hose

All new fuel hoses front to back, cleaned up fuel pump wiring, new filter

New O2 sensor for my AFR gauge

Complete coolant flush including upper block passages, repainted block & radiator

Painted wiper motor

Painted suspension & steering components, new sway bar bushings

Cleaned up triple Webers and installed new accel pump gaskets, jet covers, o-rings, etc.

Removed cluttered battery wiring, separately fused the horn, high & low beam relays, and electric window relays

Detailed engine compartment, new yellow zinc clamps to show off the beauty of these e9 engines

New upper and lower firewall insulation from CS-Werke

Flushing brakes and new blue hoses is next up.

I also made an emergency fuel pump harness so I can swap in my spare pump into the spare tire/trunk fuel hose fittings (without getting under the car) and run it off the cigar lighter socket if the existing one dies on a trip.

Finally, I had a stencil of the VGS logo custom made for the airbox, and here are the resulting bling shots:

This is the nicest it's going to look in my lifetime because from here on out I am going to drive the hell out of this car! I am tired of working on it, but this was a lot fun and satisfying to do this project, I learned a lot with the help of fellow forum members. It's ready for a long road trip at a high rate of speed!

I also didn't want to pull my engine and pay big bucks for the total rebuild on a low mileage engine so I challenged myself to do this engine-in-situ after reading the blue book on how to replace a piston, I thought what the heck I'll do all 6

I am very glad I did this because one of my pistons was missing a gudgeon circlip (the pin easily slid out from one side) and #6 cylinder rod cap bolts had lost their torque and were not very tight! Yikes. Onward...

@stphers took me under his wing and gave me invaluable advice and encouragement along the way, thanks RIck! He told me how to hone the bores and get the cross-hatch:

And polish the crank with 600 wet sand and a shoelace from below. While the pistons were at the shop getting my connecting rods put on and balanced, I did major detailing and rewiring. I had no less than 7 connections to the + side of the battery for accesories which has bothered me for years, looks like crap all cluttered. Before:

I installed a vintage style fuse box on the firewall (with the same torpedo fuses as under the dash) to fuse the relays of the horn, high & low beams, and window relays/stereo amp. I realized while doing this that not only is the low beam circuit not relayed (I changed that years ago), but neither high or low beams are fused. The horn has a fuse but it's not the relay that is fused. I also cleaned up my driving light circuit and a/c fan relay connections and wiring etc under the headlight acess panel. Here's the fuse box with beefy wiring, it's fed off the starter post and big cable from the battery:

And the result of the rewire is I now just have the original cable to the battery with no janky clutter (hmmm I need to clean up that tape):

Next I measured and filed the piston ring clearances and installed the piano tops, torqued the rod caps (new bearings), clearance is .038mm so in spec:

Put it all back together and spun the engine with no plugs in to get oil pressure. Repeated a couple times. All good. Put the plugs in and she started right up! I did the break in/ring seating procedure for 20 min then drove it 30 miles with various revs/engine braking then changed the oil. Definitively more pep and power.

Once satisfied it was running ok I put everything back together in the engine compartment (this took a week). Here is a list of what was done during this 2+ month project:

Installed euro piano top pistons

New rod bearings, rings, bores honed, crank polished

Retensioned loose oil pump chain with shims (cold start knock now gone)

New head gasket

Sanded and POR-15 repainted exhaust, all new hangers

Painted brake booster (new decal) and blower motor cover plate

Cleaned all engine components and brackets, oil pan, valve cover, etc.

Differential fluid changed

Power steering fluid changed and reservoir cleaned & repainted, new hoses and filter

Tranny cleaned, fluid drained & replaced, new Coupeking bracket (it's a beast) to be installed next

All new radiator and heater hoses and clamps

New brake booster vacuum hose

All new fuel hoses front to back, cleaned up fuel pump wiring, new filter

New O2 sensor for my AFR gauge

Complete coolant flush including upper block passages, repainted block & radiator

Painted wiper motor

Painted suspension & steering components, new sway bar bushings

Cleaned up triple Webers and installed new accel pump gaskets, jet covers, o-rings, etc.

Removed cluttered battery wiring, separately fused the horn, high & low beam relays, and electric window relays

Detailed engine compartment, new yellow zinc clamps to show off the beauty of these e9 engines

New upper and lower firewall insulation from CS-Werke

Flushing brakes and new blue hoses is next up.

I also made an emergency fuel pump harness so I can swap in my spare pump into the spare tire/trunk fuel hose fittings (without getting under the car) and run it off the cigar lighter socket if the existing one dies on a trip.

Finally, I had a stencil of the VGS logo custom made for the airbox, and here are the resulting bling shots:

This is the nicest it's going to look in my lifetime because from here on out I am going to drive the hell out of this car! I am tired of working on it, but this was a lot fun and satisfying to do this project, I learned a lot with the help of fellow forum members. It's ready for a long road trip at a high rate of speed!

Last edited:

She deserved a little love and now she looks amazing!

Great job.. Will you need to change your carb settings now with the higher compression pistons?

One last detail--paint the top of the Bosch relay to match the other 3 Hella relays.

neither are painted, the regulator is just older, and not used as my alternator is internally regulated, I should just get a new one.

One last detail--paint the top of the Bosch relay to match the other 3 Hella relays.

to be determined, I’ll sort that next

Great job.. Will you need to change your carb settings now with the higher compression pistons?

stphers

Well-Known Member

Nice Steve, that fuse box looks vaguely familiar from an early 911?

Thanks, Rick

Thanks, Rick

Wow, it looks so nice Steve! Great job.

Well done mate. Glad my pistons went to a good home. This is what the Forum is all about..