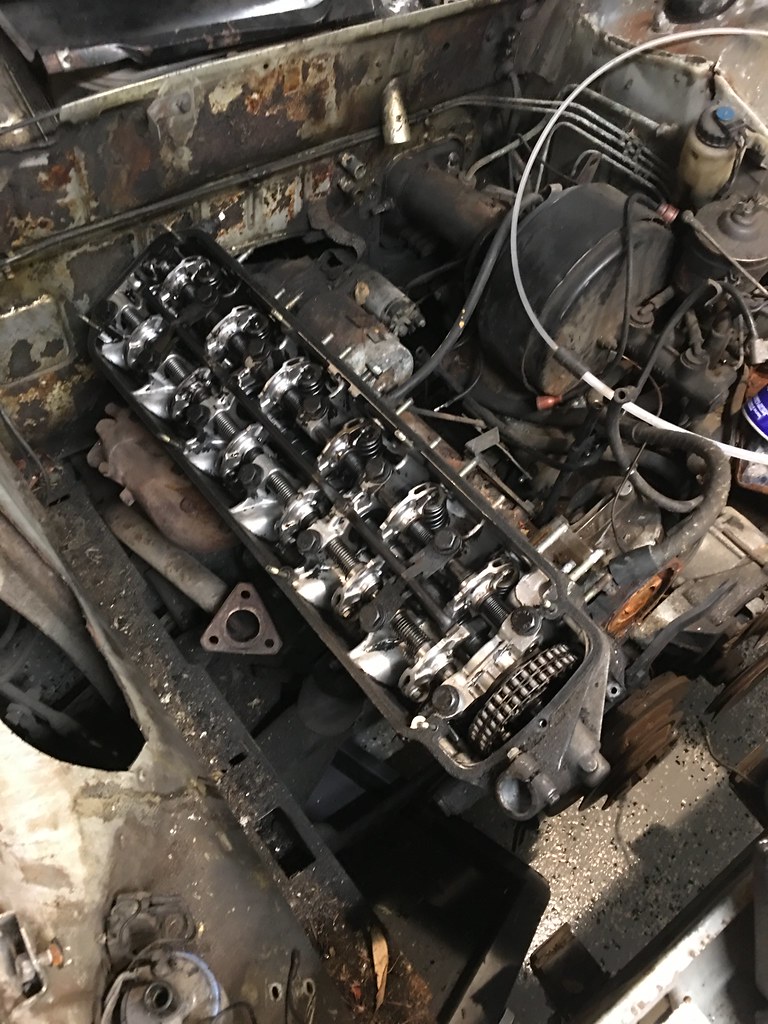

I don't own a cherry picker and I'm hesitant to buy one at this time. I don't plan to remove the motor in my project car for several years. My parts car intention all along has been to wheel the motor out the front of the car after I had cut the nose off. With the nose gone, I began the process this evening.

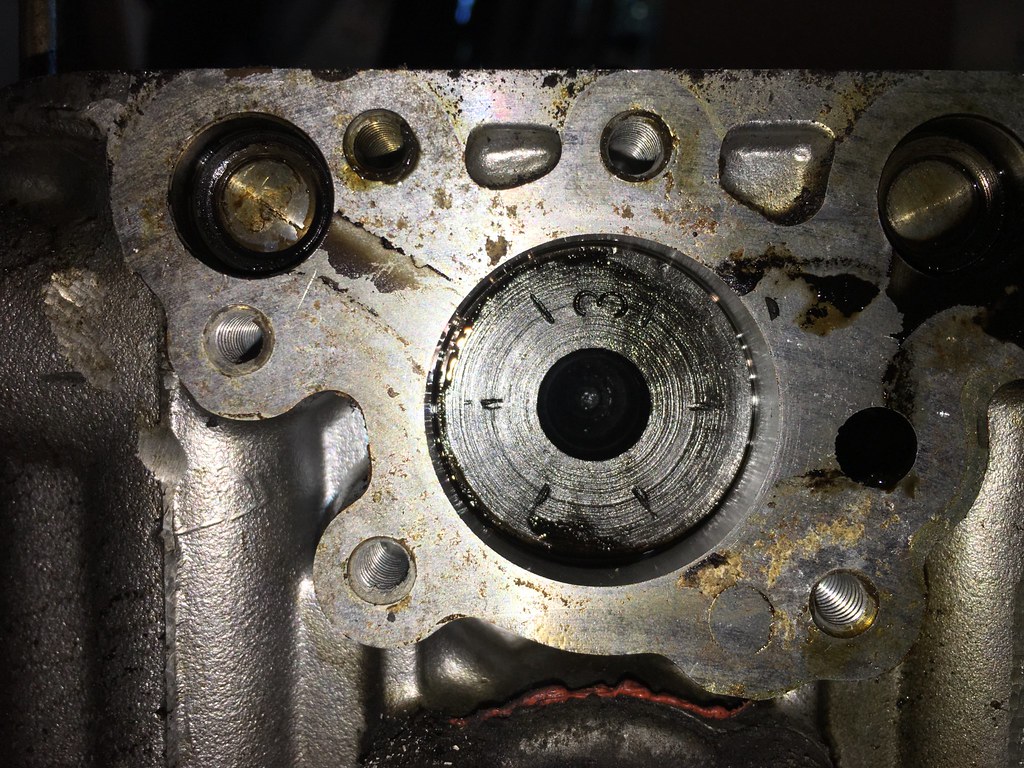

Before getting started my last bit of housekeeping included the removal of the slave cylinder. I'm sure it is well documented on this forum, but this seems like a two person job. You have two 13mm nuts up near the clutch pedal pivot and a corresponding 13mm bolts above and below the cylinder. You need to hold the bolts while loosening the nuts. This wasn't a huge deal for me with the absent windscreen, as I could straddle the firewall with my arms to reach each side. I'll add that the lower bolt head is very difficult to get a grasp on. A thin walled socket may do the trick, or holding the nut with the open end of your wrench positioned vertically over the bolt.

An interior view of the two slave cylinder nuts, above and below the rubber accordion

I also took a moment to pull the reverse switch leads and disconnect the rear braided ground strap found near the engine VIN stamp...

I really wanted to limit the amount of wrenching that has to happen under the car or in the engine bay. It was my hope that I could disconnect the driveshaft, wheel the motor out, use the transmission as leverage to flip the motor on the crate, then remove. For the most part the plan is working as described. I figured that life would be easy if I could drop the driveshaft support and slide the front driveshaft yoke right out of the rear driveshaft.

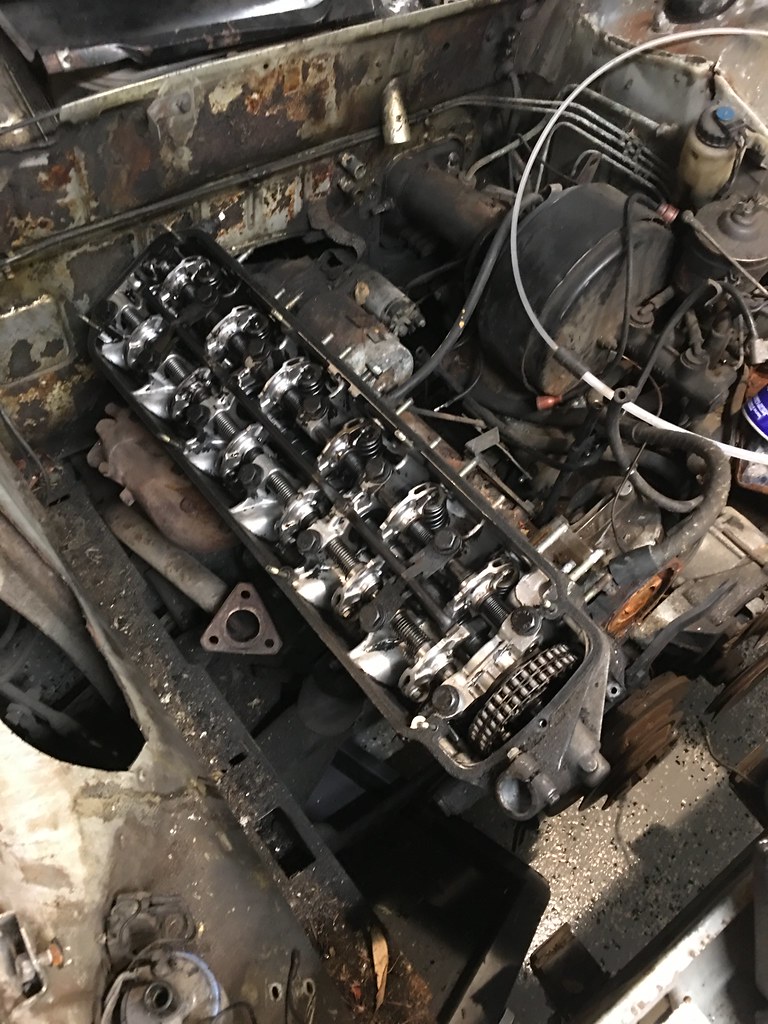

I chalked the rear wheels on both sides, then jacked the car up at the subframe. After getting the car nice and high, I placed jack stands under the frame rails just aft of where the frame curves up into the bay. If lowered the jack slightly and tested the stability of the jack stands. Once stability was confirmed I once again raised the jack until slight pressure was on the subframe. Unsure how far the transmission would drop with the crossmember removed, I stuck another jackstand under the trans. I then removed the two 13mm nuts that hold the crossmember to the car. I left the crossmember bolted to the trans though:

Extra crossmember, undercarriage is clean enough to eat off of...

Removing the driveshaft support, two 13mm nuts - no fussing with the guibo. This photo almost looks upside down but it is not. My exhaust is dropped due to the manifold removal. Note the extension on the yoke:

Next I dropped the strut tops by removing the three 19mm acorn nuts that secure the strut assembly to the inner fender. I also remembered to cut the brake lines right around this time after seeing the hard line mounts pull away from the inner fender. At this time I placed a wheel dolly under the transmission to aid the rolling process later.

Finally, I removed the four bolts holding the subframe in place. I started with the rearmost on each side. I wasn't positive about what to expect when I removed the last bolt. The subframe (and my jack) sits under cylinder number four. If the transmission wasn't attached, the engine would fall forward. I suspected that the extra 60+ lbs of the transmission and driveshaft would keep the motor from tipping. My assumption was correct and the last subframe bolt removal was uneventful.

Riding low...

This is where I called it quits. I tried pulling on the jack to separate the yoke on the driveshaft. The jack slipped off the crossmember and is now sitting under the oil pan. I tried pulling from the engine, but I'm hesitant to wiggle the car too much with the jack stands underneath.

The yoke is very close to separating. Any insight on this would be appreciated!